| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Garage Steel Frame |

|---|---|

| Brand Name: | SPDAR |

| Model Number: | 100x20x8m Height Steel Structure Warehosue |

| Place of Origin: | DONGGUAN, GUANGDONG, CHINA |

| MOQ: | 20tons |

| Price: | Negotiable |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 10000 metric ton/month |

| Delivery Time: | 15~45days |

| Packaging Details: | Packed in a iron holder and then by a container, normally 15tons ~25tons per 40HQ container, loading quantity according to member's shape and length |

| Certification: | ISO |

| Steel material standard: | Q235B/Q345B; |

| Main Structure Parts: | Welded 6mm~25mm thickness H beams & Round pipes |

| Bracing Parts: | 2.5mm thickness Galvanized C purlins & Steel Angles |

| Surface Treatment: | Red Paint |

| Clading Systerm: | Colored Steel Sheet and FRP Lighting Tiles |

| Drainage System: | Galvanized water gutter & PVC Down Pipe |

| Accessories: | High Strength Bolt & Self-tapping Screw |

| Loading: | By 40 HQ Contianer |

| Installation Time: | One Month |

| Installation Method: | By bolt |

| Application: | Warehouse/ workshop |

| Design software: | PKPM, TEKALa |

Garage Steel Frame / Steel Warehouse / Red Color Steel

Members-30000square meters

1. General Description

Garage Steel Frame / Steel Warehouse use pre-fabricated steel H

beams to build the main steel frames and use galvanized C & Z beams

as the roof and wall purlin, cladding systerm can do the glass

curtain wall , or aluminum curtain wall or use colored steel wall

and roof , or can use FRP light tiles.

Quick to fabricate,Easy to assemble,

Long using time over 50 years,

Low cost and maintenance,

Environment friendly,

Recyclable,

Lighter weight,

Excellent anti-shock and anti-impact ability.

Main component:

| 1 | Main steel frame | H section steel beam and columns, painted or Hot-dip galvanized |

| 2 | Secondary frame : | Hot-dip galvanized C/Z purlin, steel bracing, tie bar, knee brace, edge cover etc. |

| 3 | Roof panel : | EPS sandwich panel , glass fiber sandwich panel , rock wool sandwich panel , and PU sandwich panel or Single steel sheet |

| 4 | Wall panel : | Sandwich Panel or Corrugated Steel Sheet |

| 5 | Tie Rod: | Circular Steel Tube |

| 6 | Brace: | Round Bar |

| 7 | Knee Brace: | Angle Steel |

| 8 | Roof Gutter: | Color Steel Sheet or galvanized plate sheet |

| 9 | Rainspout: | PVC Pipe |

| 10 | Door: | Sliding Sandwich Panel Door or Rolling Metal Door |

| 11 | Windows: | PVC/Aluminum Alloy Window |

| 12 | Connecting: | High strength bolts |

| 13 | Packing: | There are a steel holder to support all steel members |

| 14 | Drawing: | We can make the design and offer according to your requirement or your drawing |

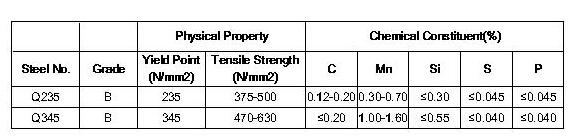

2. Material Specification Datas for reference

3. Process method

CNC Steel plate cutting---- H Shape Forming ------ Welding By ARC

Soldering Machine---- Straight/ Shape Fixing --- Joint Steel plate

weld by manual--- Sand-blasting---- Paint Treatment Step----Loading

Packing

4. Loading & Installation for reference

Loaidng in factory

Loading at the project site

Installation a job site

5. Before sales service

We have professional engineer teams to make the structural drawing

and building drawing according to customer's requirements.

If you are planing to build a Garage Steel Frame Building, please

send your requirements to me, and then we can give you the best

solution.

| BUILDING INFORMATION FORM | ||||||||

| We will give you professional technical solution if you can fill this for and contact with us by e-mail, fax or tel which listed at the bottom of this form. | ||||||||

| Compay Name: | ||||||||

| Client | Tel/Fax: | E-mail: | ||||||

| Building Basic Information | ||||||||

| Project: | Project No.: | |||||||

| Location | Building Usage | Total area | ||||||

| Length (m) | Width (m) | Eave Height (m) | ||||||

| Roof material | ||||||||

| Wall material | ||||||||

| Design Load and Meteorological Conditions | ||||||||

| Wind load (kn/m2) | Wind speed (m/sec) | Snow load (kn/m2) | ||||||

| Rainfall Capacity | Earthquake Grade | |||||||

| Please fill out the below information if your building has the mezzanine | ||||||||

| Height of Mezzanine(m) | Usage of mezzanine | |||||||

| Live load on mezzanine(kn/m2) | ||||||||

| Please fill out the below information if your building has the crane | ||||||||

| Capacity (t) | Span (m) | Quantity | ||||||

| Hoisting height (m) | Other information about crane | |||||||

| Building sketch | ||||||||

6. After- Sales

We can offer you the whole set installation drawings for assembly

conduction.

Also we have professional installation teams, if you need , we can

offer the installation engineers to help you to conduct the whole

buildings installation.

|