| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Liquid Oxygen Plant |

|---|---|

| Brand Name: | HANGYANG |

| Model Number: | KDON |

| Certification: | CE/ASEM/GB |

| Place of Origin: | China |

| MOQ: | 1 set |

| Price: | negotiation |

| Supply Ability: | according to actual requirement |

| Delivery Time: | according to actual requirement |

| Packaging Details: | wooden case, nude packing, container |

| Product Name: | KDON-2100/75 Liquid Oxygen Plant |

| Usage: | Produce LIN/GAN/L/GOX/LOX |

| Output(Nm3/h): | 2000~2500 |

| Service: | Engineers available to commissioning service overseas |

| Material: | Carbon steel, Al, stainless steel |

| Package: | Seaworthy packing |

Liquid Oxygen Plant KDON-2100/75 Nm3/h Coal chemical industry Welding Gas Metal Processing

Specifications:

Liquid Oxygen Plant KDON-2000~2500 Series manufactured by our company

MODEL CONTENTS | KDON-2500/1200 | KDON-2000Y | KDON-2000Y/100Y | KDON-2000Y | KDON-2850Y/900Y | |

GAN/LIN flow | Nm3/h | 4300/1200 | 2000 | 100/100 | 3000 | 4000/900 |

GAN/LIN purity | ppm | ≤1ppmO2 | ≤1ppmO2 | ≤1ppmO2 | ≤10ppmO2 | ≤3ppmO2 |

GOX/LOX flow | Nm3/h | 1500/2000 | 2000Y | 4000/2000 | 2000Y | 1600/2850 |

GOX/LOX purity | ppm | 99.6% O2 | 99.6% O2 | 99.6% O2 | 99.6% O2 | 99.6% |

GAN/LIN pressure | MPa | 0.015/0.2 | 0.01 | 0.005/0.2 | 0.01 | 0.014/0.3 |

GOX/LOX pressure | MPa | 2.5/0.16 | 0.12 | 0.015/0.15 | 0.12 | 0.024/0.3 |

LAr flow | Nm3/h | 110 | 60 | 200 | 150 | |

LAr purity | ppm | ≤2ppm O2,≤2ppm N2 | ≤2ppm O2,≤2ppm N2 | ≤1ppmO2,≤2ppmN2 | ≤2ppm O2,≤3ppm N2 | |

LAr pressure | MPa | 0.16 | 0.16 | 0.16 | 0.16 | |

Typical Product: KDON-2100/75 Liquid Oxygen Plant

Output, purity and pressure

Product | Output Nm3/h | Purity | Pressure MPa(G) |

GAN/LIN | 75 | 10ppmO2 | 0.4 |

GOX/LOX | 2100/900 | ≥99.6%O2 | 0.024/0.12 |

LAr | 100 | ≤2ppm O2,≤2ppm N2 | 0.16 |

Description:

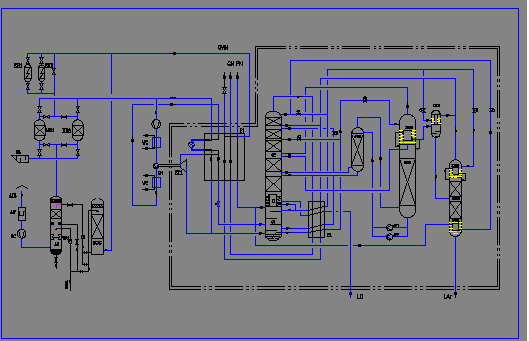

The proposed plant employs a process in which air is purified by molecular sieve and refrigerated by refrigeration boosting turbine single expander; structural packing is applied and argon is extracted through full rectification.

The extraction of argon is achieved by means of complete cryogenic rectification.

LOX is extracted from the main condensation evaporator to effectively prevent the accumulation of such dangerous impurities as hydrocarbons.

The application of DCS can realize the integrated control at center room, local cabinet and on site, and can effectively monitor the production duration of air separation plant.

Applications:

Competitive Advantage:

|