| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Downspout Roll Forming Machine |

|---|---|

| Brand Name: | Sussman |

| Model Number: | SS - RM |

| Certification: | CCC, SGS, ISO9001, CE |

| Place of Origin: | Wuxi Jiangsu China |

| MOQ: | 1 set |

| Price: | negotiable |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 10 sets per month |

| Delivery Time: | 55 - 65 days |

| Packaging Details: | Standard packing |

| Forming speed: | 12-15m/min |

| Roller station: | 16 - 18 stations |

| Main motor power: | 11Kw |

| Hydraulic station power: | 7.5Kw |

| Company Info. |

| Sussman Machinery(Wuxi) Co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

Professional 12-18 Station Downspout Roll Forming Machine Automatic Half Rond Type Rain Gutter Roll Former

Technical Parameter

| Item NO | Description | Offered specification |

| 1.0 | Roll forming machine | |

| 1.1 | Rolling speed | 10-15m/min(not include cutting time) |

| 1.2 | Rolling thickness | 0.3-0.6mm |

| 1.3 | Raw material | Galvanized steel sheet |

| 1.6 | dimension | 3500×1600×1500(mm) |

| 1.7 | Effective width | 60mm |

| 1.8 | Roller stations | 13 stations One stage for embossing |

| 1.9 | Roller material | 45#forge steel, coated with chrome |

| 1.10 | Shaft diameter | Φ70mm ,material is 45# forge steel |

| 1.11 | Transmission | By chain 1 inch |

| 1.12 | Material of chain | 45# forged steel with frequency quenching, 12A |

| 1.14 | Material of cutting | Cr12Mov with quench HRC58-62° |

| 1.15 | Tolerance | 6m+-1.5mm |

| 1.16 | Frame | H type steel |

Main Components

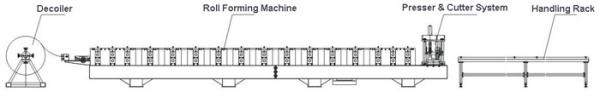

| Machine Component name | Quantity |

| 3 ton passive decoiler | 1Set |

| Main roll forming machine | 1Set |

| Hydraulic station | 1Set |

| Cutting device | 1Set |

| Finished products tabel | 2Set |

| PLC control system | 1Set |

| Spare parts | 1Set |

Advantage for

1. Reasonable Price

2. High Quality

3. 12 Months Warranty

4. More Than 10 Years Experience

5. Durable

6. Reliable

Working Flow

Decoiler ---- Feeding --- Levelling--- Cutting ---Roll forming--- Run out table

Machine picture

Production process

|