| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Roof Panel Roll Forming Machine |

|---|---|

| Brand Name: | Sussman |

| Model Number: | SS-KS |

| Certification: | CCC, SGS, ISO9001, CE |

| Place of Origin: | Wuxi Jiangsu China |

| MOQ: | 1 set |

| Price: | negotiable |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 10 sets per month |

| Delivery Time: | 55 - 65 working days after deposit |

| Packaging Details: | Standard package with film, plastic and steel wire. (or customized) |

| Material of cutting blade: | Cr12 steel |

| Roller material: | Cr40 Steel with quenching |

| Control system: | PLC with touch screen |

| Power supply: | 380V, 50Hz, 3Phase |

| Dirve system: | Chain drive |

| Forming speed: | up to12-15m/min |

| Company Info. |

| Sussman Machinery(Wuxi) Co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

Roof panel K-Span Roll Forming Machine

Technical Parameter

Item NO. | Description | Offered Specification |

1 | Product Line speed | 12-15m/min(not include cutting ) |

2 | Suitable material thickness | 0.6-2.0mm |

3 | Raw material | Pre-paint Color Steel Coil yield strength≤G250MPa |

4 | Dimension | 10400mm × 2250mm × 2300mm about |

5 | Levelling device | 7 roller levelling including 3 top rollers and 4 bottom rollers |

6 | Roller stations(stages) | 16 stations |

7 | Roller material | bearing steel, quenching treatment |

8 | Shaft diameter | Φ76mm ,material is 45# forge steel |

9 | Transmission | By chain 1.2 inch 20A double chain with longer shafts |

10 | Material of chain | 45# forged steel with frequency quenching, 12A |

11 | Material of cutting | Cr12Mov with quench HRC58-62° |

12 | Main motor power | 7.5kw |

13 | Motor power of hydraulic station | 5.5kw |

14 | Hydraulic station pressure | 12Mpa |

15 | Machihne Weight | 10 Ton |

15 | Tolerance | 6m+-1.5mm |

16 | Frame | H Beam |

| Main list |

| 1 set |

| 1 set | |

| 1 set | |

| 1 set | |

| 1 unit | |

| 1 unit | |

| 2 units | |

| 1 unit |

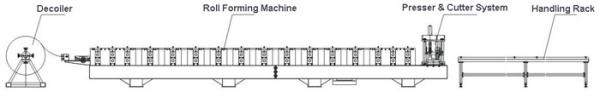

Working Flow of Roll Forming Machine

Uncoiling—Feeding&Leveling--Roll forming—Cutting—Products

collecting

Machine Description

The no girder arch roof roll forming machine is designed and built

to produce large span steel sheet for

roofing panel. It is comprised of mechnical expansion decoiler,

roll forming machine unit, hydraulic mould

cutting device, curving panel machine unit, PLC control system,

hydraulic system, run-out tables for

straight and curve panels and all other accessories. Customer can

choose mobile truck as foundation for

flexible use.

Advantage of machine

1. Reasonable Price

2. High Quality

3. 12 Months Warranty

4. More Than 10 Years Experience

5. Durable

6. Reliable

Profiles

Forming Machine Pictures

|