| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Stainless Steel Tube |

|---|---|

| Brand Name: | TORICH |

| Model Number: | GB13296 |

| Certification: | ISO 9001 ISO 14001 TS 16949 EN 10204.3.1 LR KR |

| Place of Origin: | CHINA |

| MOQ: | 0.5 Tons |

| Price: | negotiable |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 60000 Tons per Year |

| Delivery Time: | 30-45 Days |

| Packaging Details: | in wooden, hexagonal box or other seaworthy ways |

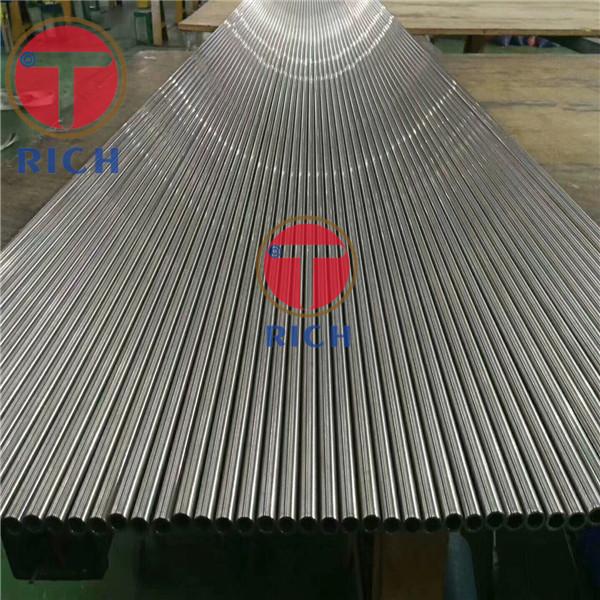

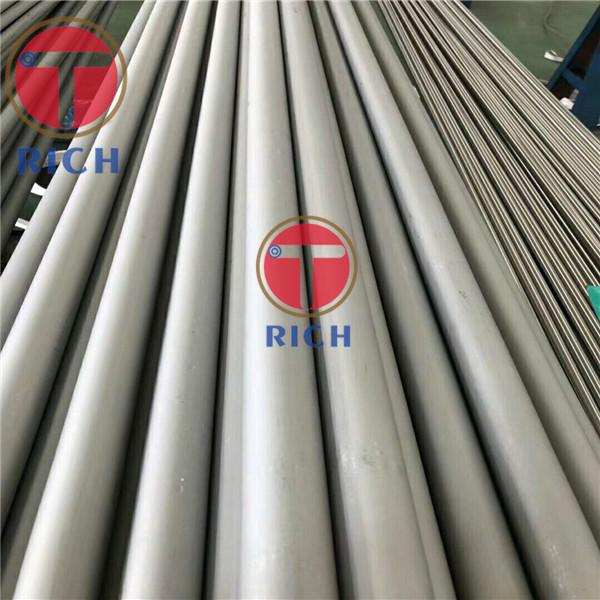

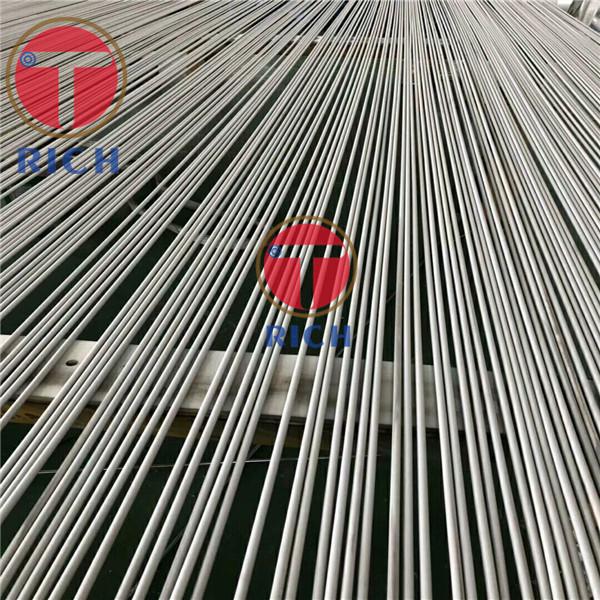

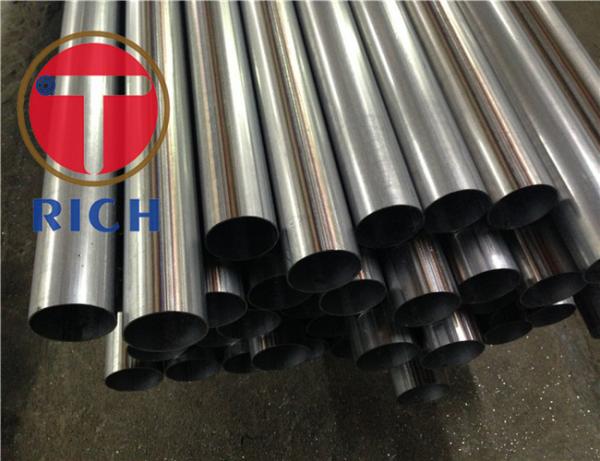

| Product name: | GB13296 0Cr18Ni9 Seamless Stainless Steel Tubes for Boiler and Heat Exchanger |

| Keyword: | 0Cr18Ni9 Seamless Stainless Steel Tubes for Boiler and Heat Exchanger |

| Type: | Stainless Steel Tubes |

| Surface: | Galvanized Coated |

| Material: | 0Cr18Ni9 1Cr18Ni9 1Cr19Ni9 |

| Usage: | Boiler and Heat Exchanger |

| Shape: | Round Shape |

| Length: | 4-12m |

| OD: | 6-159mm |

| WT: | 1-14mm |

| Company Info. |

| TORICH INTERNATIONAL LIMITED |

| Verified Supplier |

| View Contact Details |

| Product List |

GB13296 0Cr18Ni9 Seamless Stainless Steel Tubes for Boiler and Heat Exchanger

Application: Boiler and Heat Exchanger

Size:WT 1~14mm

OD 6-159mm

L 4-12m

Production Method of Steel:Refining outside the furnace or electric arc furnace slag remelting process

Production Method of Steel Tube:Hot rolled(extrusion and expansion)or cold drawn seamless method.

Permissible deviation of outside diameter and wall thickness

| Classification | Nominal size | Allowable deviation | |

| W-H | OD | ≤140 | ±1.25%D |

| >140 | ±1%D | ||

| S | ≤3 | -40%S | |

| >3~4 | -35%S | ||

| >4~5 | -33%S | ||

| >5 | -28%S | ||

| W-C | OD | 6~30 | +0.15 -0.20 |

| >30~50 | ±0.30 | ||

| >50 | ±0.75%D | ||

| S | D≤38 | +20%S | |

| D>38 | -22%S | ||

Steel grade and chemical composition

| Number | Steel grade | Chemical Composition % | ||||||||

| C | Si | Mn | P | S | Ni | Cr | Mo | Ti | ||

| 1 | 0Cr18Ni9 | ≤0.07 | ≤1.00 | ≤2.00 | ≤0.035 | ≤0.030 | 8.00~ 1.00 | 17.00~ 19.00 | — | — |

| 2 | 1Cr18Ni9 | ≤0.15 | ≤1.00 | ≤2.00 | ≤0.035 | ≤0.030 | 8.00~ 10.50 | 17.00~ 19.00 | — | — |

| 3 | 1Cr19Ni9 | 0.04~0.10 | ≤1.00 | ≤2.00 | ≤0.035 | ≤0.030 | 8.00~ 12.00 | 18.00~ 20.00 | — | — |

| 4 | 00Cr19Ni10 | ≤0.030 | ≤1.00 | ≤2.00 | ≤0.035 | ≤0.030 | 8.00~ 12.00 | 18.00~ 20.00 | — | — |

| 5 | 0Cr18Ni10Ti | ≤0.08 | ≤1.00 | ≤3.00 | ≤0.035 | ≤0.030 | 9.00~ 12.00 | 17.00~ 19.00 | — | ≥5C |

| 6 | 1Cr18Ni11Ti | 0.04~0.10 | ≤0.75 | ≤2.00 | ≤0.030 | ≤0.030 | 9.00~ 13.00 | 18.00~ 20.00 | — | 4Xc~ 0.60 |

| 7 | 0Cr18Ni11Nb | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.035 | ≤0.030 | 9.00~ 13.00 | 17.00~ 20.00 | — | — |

| 8 | 1Cr19Ni11Nb | 0.04~0.10 | ≤1.00 | ≤2.00 | ≤0.035 | ≤0.030 | 9.00~ 13.00 | 17.00~ 20.00 | — | — |

| 9 | 0Cr17Ni12Mo2 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.035 | ≤0.030 | 11.00~ 14.00 | 18.00~ 20.00 | 2.00~ 3.00 | — |

| 10 | 1Cr17Ni12Mo2 | 0.04~0.10 | ≤0.75 | ≤2.00 | ≤0.030 | ≤0.030 | 11.0~ 14.00 | 16.00~ 20.00 | 2.00~ 3.00 | — |

Hardness

| Organization type | Steel grade | Hardness | ||

| HBW | HRB | HV | ||

| Austenitic | 00Cr18Ni10,0Cr19Ni9N,00Cr17Ni13Mo2,0Cr17Ni12Mo2N | ≤217 | ≤95 | ≤220 |

| 0Cr18Ni13Si4 | ≤207 | ≤95 | ≤218 | |

| Others | ≤187 | 90 | 200 | |

| Ferrite | 1Cr17 | ≤183 | — | — |

| 00Cr27Mo | ≤219 | — | — | |

|