| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Metal Stamping Dies |

|---|---|

| Brand Name: | METS |

| Place of Origin: | XIAMEN.CHINA |

| MOQ: | 1 |

| Price: | Negotiable |

| Payment Terms: | TT,LC |

| Supply Ability: | 25 sets per month |

| Delivery Time: | 7days-35days |

| Packaging Details: | Wooden case without need of fumigation |

| Model Number: | P001 |

| Type of die: | Progressive die |

| Treatment: | Normalizing |

| Mould life: | 4 million strokes |

| press force: | 45Ton |

| Tolerance: | ±0.06mm |

| Main tooling material: | D2 |

| Production material: | aluminum |

| Cavity: | 4 rows |

| Thickness: | 0.5mm |

| Processing way: | WEDM |

| Company Info. |

| Xiamen METS Industry & Trade Co., Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

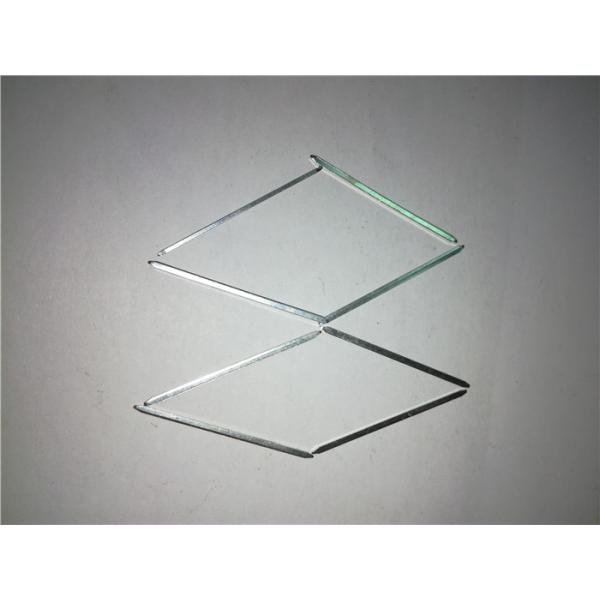

Multi-cavity compound die / mold for aluminum blunt needles

Compound Die Stamping is the process where the die separates or blanks the part from a steel strip in one stroke. A Compound Die will perform multiple cuts or punches in one stroke, as compared to multiple strokes. This is a very cost effective method for stamping medium to high volume parts while keeping labor and die costs down. Compound Dies are often used to stamp simpler flat parts such as washers.

Here at METS Precision-Tool it’s our goal to design and build our Compound Dies to exceed 100 strokes per minute to support high volume production. We can achieve this by building in sensors and other accessories to protect the die from damage. Cycle time is always kept in mind when designing and building our Compound Die tooling. We can build the die to stamp the part at the accuracy you need.

Parts are produced when the feed system pushes (strip or coil stock) of raw material into the Compound Die; at each stroke or cycle a finished flat part will blanked or released from the raw material. The feed rate of the material is determined by the size of the part. Larger parts need more time to exit the die, where smaller parts exit quicker allowing for faster run times. Typically, compound dies do not require a cut-off station because the parts are blanked through from the strip, but many times is added to help manage scrap material. Finished parts will be removed from the die by a knock-out and will fall onto a chute or slider where they flow into the collection bin. The scrap will exit the die in strip form or in piece form depending on if you’ve included a scrap cut-off station. Scrap can be collected in bins or hoppers on the exit end of the die

| General Capabilities | Design Modeling 2D, 3D,processing,assembling | Die Location Technical Support | Inspection |

| Detail Tooling Documentation | DFMEA/PFMEA | Quick Building Prototypes | |

| Die Types | Forming Dies | Precision Progressive Stamping Dies | Secondary Dies |

| High Speed Steel Stamping Dies | Precision Blanking Dies | Forming Die | |

| Tooling Material | Carbide(CD650,V3,KD20) | ASP-23 | ASP-60 |

| S55C---45#55 | AL7075 | SKD11 | |

| Tooling Life | 50 Million to 1000 Million Times | ||

| Die Concept | 2-Plate Die | 3-Plate Die | Module Die |

| Production Equipment | CNC | SODICK Nice Surface EDM | P/G |

| Drill | SODICK Wire Cutting Machine | J/G | |

| Milling Machine | WAIDA Profile Grinder Machine | ||

| Stamping Equipment | AIDA | PURDER | MICO |

| MICO | |||

| Stamping Product | Custom Stamping | SIM shrapnel | Spring clip |

| Battery shrapnel | Shield Drawing | Press-Fit Terminal | |

| Lead Frame | Power Contact Terminal | PC Terminal parts | |

| Additional Services Provided | Custom Packing | Packaging | Heat Treat |

| Plating | |||

| Delivery | 3-5 Week | 3-6 Week | 4-7 Week |

Q: What’s your manufacture capability?

---- We use Sodick/Charmilles to frabricate die inserts,dimension

we can do is +/-0.002mm.

Q: Can you make all the dimensions are according to our

design/samples?

---- We can guarantee that all the dimensions are made according to

your drawing/sample.Please notice that dimension tolerence we can

do is +/-0.003mm.

Q: Did the stamping die suit for my press machine?

--- The stamping die is made according to your press machine’s

specification.Before start making die parts,we will send the design

for your approval.

Q: What’s your advantage compare with other supplier’s on the

market?

---- We are stamping factory,have a team contains die

design,making,maintance and stamping production.We know how

important the good mold for stamping production.

---- All our engineers are with more than 10 years working

experience.They are more professional on precision stamping field.

---- All the die parts we made are by Slow-speed wire EDM,can

gurantee the dimension.Many of them make it by middle-speed wire

EDM/fast-speed wire EDM

Stamping die details:

|