| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Valve Body Casting |

|---|---|

| Brand Name: | Rongbao |

| Model Number: | OEM |

| Certification: | ISO9001 |

| Place of Origin: | Xi'an China |

| MOQ: | 100 |

| Price: | $1-500 |

| Payment Terms: | T/T, L/C |

| Supply Ability: | 100000 |

| Delivery Time: | 4 weeks |

| Packaging Details: | Carton and Wood |

| Product Name: | Valve Body Casting |

| Material: | ZL101A |

| Casting Weight: | 4.95KG |

| Casting Process: | Gravity Casting |

| Standards: | ASTM,AISI,DIN,BS |

| Surface treatment: | powder coating, brushing, polishing |

Valve Body Aluminum Casting, Gate valve, globe valve, plug valve, ball valve, butterfly valve

Robot Arm Aluminum Casting is aluminum arm, Hydraulic and electric

Product Introduction

NOTICE:All the products on our website indicate the ranges we can manufacture and our production capability.

We offer cast aluminum products according to customer’s drawings or samples.

Please feel free to contact us if you have any questions or suggestions about our business.

Product Specification

| Dimension Tolerance | CT8 |

| Surface Roughness | Ra6.3-12 |

| Manufacture | OEM/ODM |

| Certificate | ISO9001:2015 |

| Standard | ASTM, DIN,JIS, EN, ISO, GB |

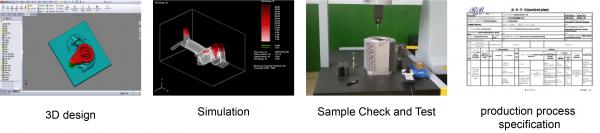

| Software | Pro/E,UG, Solidworks, Auto CAD, PDF |

| Material | A356, A380, aluminum alloy or according to your requirements |

| Machining | CNC turning, milling, drilling, grinding, cutting, reaming and threading |

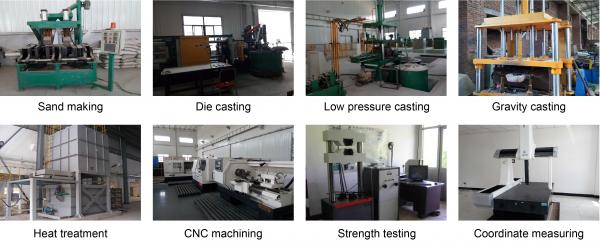

| Service | Sand casting, die casting, low pressure die casting, Gravity casting and CNC Machining |

| Testing facility | Spectrometer, Tensile test machine, Hardness test machine, CMM (Coordinate Measuring Machine) |

| Finished | Polishing, sand blasting, heat treatment, painting, powder coating, anodizing, electroplating, Chrome plating, mirror polishing. |

| Product | All kinds of aluminum casting parts |

Product Feature and Application

Metal casting is unique among metal forming processes for a variety of reasons. Perhaps the most obvious is the array of molding and casting processes available that are capable of producing complex components in any metal, ranging in weight from less than an ounce to single parts weighing several hundred tons. Foundry processes are available and in use that are economically viable for producing a single prototype part while others achieve their economies in creating millions of the same part.

The capability to combine a number of individual parts into a

single integral casting, reducing overall fabrication costs.

The design freedom of casting minimizes machining costs and excess

metal.

Patterns used in casting lower in cost compared to other types of

tooling.

Castings require a comparatively short lead time for production.

Casting are used in 90% or more of all manufactured goods and in

all capital goods machinery used in manufacturing. The diversity in

the end use of metal castings is a direct result of the many

functional advantages and economic benefits that castings offer

compared to other metal forming methods. The beneficial

characteristics of a cast component are directly attributable to

the inherent versatility of the casting process.

Quality Control

Casting Process

Packaging & Delivery

Our Customers

Office & Factory

Production Equipment

Common Problems in Casting Products

Shrinkage refers to the percentage reduction in size of an alloy from liquid to solid, and from cooling to room temperature.

The size of shrinkage is related to the structural features, wall thickness, chemical composition and technological factors of the alloy.

Generally speaking, the linear shrinkage of zinc alloy is 0.6%~0.8% when free contraction and 0.3%~0.6% when blocked contraction.

|