| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Stainless Steel Tube |

|---|---|

| Brand Name: | TORICH |

| Model Number: | TP201 TP304 TP304L |

| Certification: | SO9001:2008 ,TS16949 |

| Place of Origin: | China |

| MOQ: | 1 ton |

| Price: | negotiable |

| Payment Terms: | T/T, L/C, D/A, D/P, Western Union, MoneyGram |

| Supply Ability: | 6000ton |

| Delivery Time: | 45-60days |

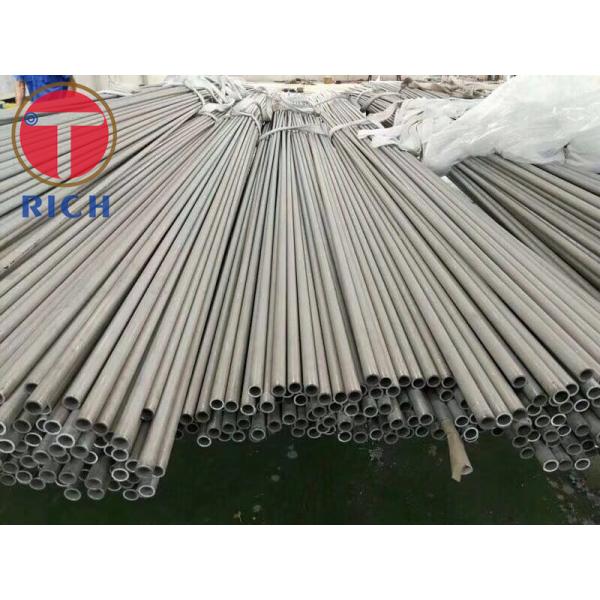

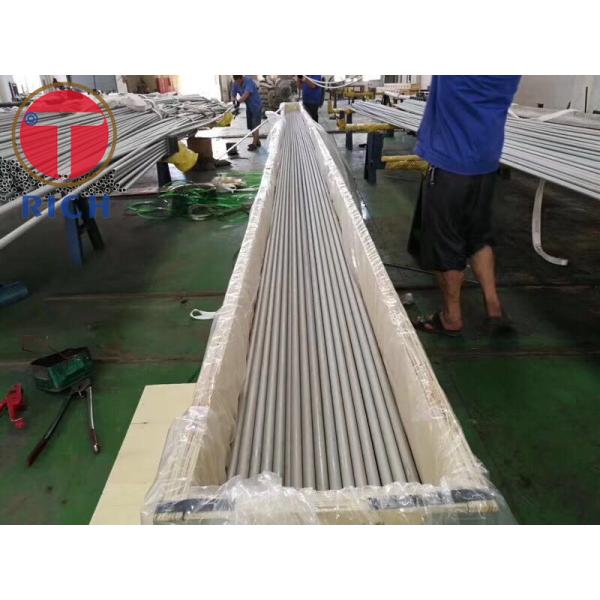

| Packaging Details: | In bundles with seaworthy packing |

| Product name: | Seamless Stainless Steel Tube |

| Standard: | ASTM A269 |

| Material: | TP201 TP304 TP304L |

| Type: | Seamless |

| Terms Of Trade: | FOB or CIF |

| Brand: | TORICH |

| Transportation: | Ocean, air |

| Certificate: | ISO9001, TS16949 |

| End protector: | Plain |

| MTC: | En10204.3.2B |

| Company Info. |

| TORICH INTERNATIONAL LIMITED |

| Verified Supplier |

| View Contact Details |

| Product List |

ASTM A269 TP201 TP304 TP304L Seamless Stainless Steel Tube

Size range: I.D.≥6.4mm W.T. ≥0.51mm L: according to customer requirement

Steel Grade and Chemical Compositions:

| Grade and chemical composition% | |||||||||

| C | Si | Mn | P≤ | S≤ | Cr | Mo | Ni | Other | |

| 201 | ≤0.15 | ≤1.00 | 5.5-7.5 | 0.06 | 0.03 | 16-18 | - | 3.5-5.5 | N≤0.25 |

| 202 | ≤0.15 | ≤1.00 | 7.5-10.0 | 0.06 | 0.03 | 17-19 | - | 4.0-6.0 | N≤0.25 |

| 301 | ≤0.15 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 16-18 | - | 6.0-8.0 | - |

| 302 | ≤0.15 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 17-19 | - | 8-10.0 | - |

| 303 | ≤0.15 | ≤1.00 | ≤2.00 | 0.2 | ≥0.015 | 17-19 | ≤0.6 | 8.0-10.0 | - |

| 304 | ≤0.08 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 18-20 | - | 8-10.5 | - |

| 304L | ≤0.03 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 18-20 | - | 9-13 | - |

| 305 | ≤0.12 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 17-19 | - | 10.5-13 | - |

| 309S | ≤0.08 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 22-24 | - | 12-15 | - |

| 310S | ≤0.08 | ≤1.5 | ≤2.00 | 0.045 | 0.03 | 24-26 | - | 19-22 | - |

| 316 | ≤0.08 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 16-18 | 2-3 | 10-14 | - |

| 316L | ≤0.03 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 16-18 | 2-3 | 12-15 | - |

| 317 | ≤0.08 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 18-20 | 3-4 | 11-15 | - |

| 317L | ≤0.03 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 18-20 | 3-4 | 11-15 | - |

| 321 | ≤0.08 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 17-19 | - | 9-13 | Ti≥5×C |

| 405 | ≤0.08 | ≤1.00 | ≤1.00 | 0.04 | 0.03 | 11.5-14.5 | - | ≤0.6 | AL0.1-0.3 |

| 420F | 0.26-0.4 | ≤1.00 | ≤1.25 | 0.06 | ≥0.15 | 12-14 | ≤0.6 | ≤0.6 | - |

| 430 | ≤0.12 | ≤0.75 | ≤1.00 | 0.04 | 0.03 | 16-18 | - | ≤0.6 | |

Manufacture:

Tubes are made by seamless process.

At the manufacturer’s option,, tubing may be furnished either hot finished or cold finished.

Surface Condition:

The tubes shall be pickled free of scale,. When bright annealing is used, pickling is not necessary.

Test and Inspection:

- Mechanical Test

- Tension Test

- Flaring Test

- Flange Test

- Reverse Test

- Hardness Test

- Hydrostatic or Nondestructive Electric Test

|