| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Roof Tile Roll Forming Machine |

|---|---|

| Brand Name: | CHBEST |

| Model Number: | CHBEST-800 |

| Certification: | CE/ISO |

| Place of Origin: | China,Hebei |

| MOQ: | 1set |

| Supply Ability: | 15sets/month |

| Delivery Time: | 35days |

| Packaging Details: | Standard |

| Name: | Trapezoidal Roof Tile Metal Making Roll Forming Machine PLC Control 380V |

| Cutting Type: | Hydraulic |

| Thickness: | 0.3-0.8mm |

| Color: | As your require |

| Material: | PPGI/GI |

| Warranty: | 2 year |

| Company Info. |

| Cangzhou Best Machinery Co., Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

Trapezoidal Roof Tile Metal Making Roll Forming Machine PLC Control 380V

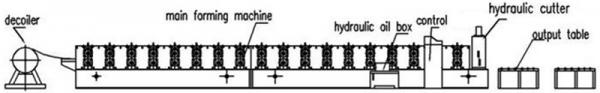

Machine Component

| Decoiler | 1set |

| Roll Forming | 1set |

| Pressing And Cutting Device | 1set |

| PLC Control System | 1set |

| Hydraulic Pump | 1set |

| Output Table | 1set |

Decoiler

| Width | 1500mm |

Inner Diameter | 450-550mm |

| Out Diameter | 1500mm |

Max. Loading Capacity | 5000kgs |

| Type | Manual Or Hydraulic |

Roll Forming Machine

Material Thickness: 0.3-0.8mm PPGI and GI

NO. of roller Stations: 11roller stations

Material for Rollers: high grade 45# steel polished and coated with

chrome HRC55-60°

Frame panel thickness: 20mm

Bottom frame: 36# H-section steel

Motor Power: 3kw

Driven type: 1.0"Chain

Diameter of shaft: 70mm

Material for shaft: high grade 45# steel polished and coated with chrome HRC55-60°

Pressing And Cutting Device

Material for Cut-Off Modular:Cr12 steel after treatment

Hardness for Heat Treatment:HRC55 – 60°

Cut-Off Type:Hydraulic, Automatic Cut-Off

Motor for Hydraulic Stand: 3kW

Press tool material: Cr 12 steel after heat-treated

Control System

| Type | PLC Frequency Control System with touch screen |

PLC Brand | Delta |

Encoder Brand | Omron |

Length Error | ±2mm |

Language | English and Chinese |

| Voltage | 380v/50HZ, 3Phase |

Hydraulic Pump

Motor power: 3 kw

Oil type: 46# hydraulic oil

Pump brand: China brand

Output Table

No power type

Length: 2m

Main machine

The function of the main machine is roll forming the steel sheet to the profile customer the steel sheet to the profile customer want and then cut the steel sheet into piece.

The material of our roller is GCR15/CR12/CR12MOV,and our shaft and roller all be electroplate to keep from rust.

The advantage of metal roofing machine, double layer roll forming machine:

1. Good quality: We have a professional designer and experienced engineer team.And

the raw material and accessories we use are good.

2. Good service: we provide the technical support for whole life of our machines.

3.Guarantee period: within one year since the date of finishing commissioning. The guarantee covers all the electric, mechanic and hydraulic parts in the line except for the easy-worn parts.

4. Easy operation:All machine cotrolling by PLC computer controlling systerm.

5. Elegant apperance:Protect the machine from rust and the painted colour can be customized

6. Reasonable price:We offer the best price in our industry.

Maintance and the service of the machine

Daily maintenance with meticulous care plays an important part in

extension the equipments’ operation time and the quality of rolling plank. Therefore, please do the following things in your

daily

1.The hydraulic tank must be filled with 32# or 46# hydraulic oil

before using. The amount of oil is subject to the oil mark

2. Add and daub lube often to the outside parts. (Such as driving

chain,Scissors, gears, rollers, )

3. Wipe the surface dust of roller often and particularly work

outside. If you do not use it for long time ,you should daub

machine and lube in the roller surface and you need clean it when

you use next time.

4. If the equipment does not use for long time, you should use

plastics cloth or other articles to cover it and notice to avoid

rain and damp, especially electrical controlling box

5. Cutting device should add lube to the places where need lube to

the request

6. Usually look into hydraulic station and the oil quantity of

deceleration machine, you should add in time when oil quantity

shortage

7. Electrical components should be guaranteed to work in a dry

environment, such as damp. Rain should continue to work after

drying.

Work Flow

Decoiler--------feeding--------roll forming--------pressing and cut to length-----output table

Our Service

| Pre-Sales-Service | If buyers visit our factory and check the machine, we will teach you how to install and use the machine, and also train your workers/technician face to face. Without visiting, we will send you user manual and video to teach you to install and operate. |

| After-Sales-Service | Training how to instal the machine, training how to use the machine. Engineers available to service machinery overseas. If buyer needs our technician to go to your local factory,please arrange board and lodging and other necessary things. |

Packing Detall

1*40 GP container ; main machine naked and fastened with iron wire

in the container.

2.rollers were painted with oil and packed with plastic film.

3.electrics devices be packed with wooden box.for Standard export packing.

4. All Components Fixed by steel wire with Container.

|