| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Seamless Steel Tube |

|---|---|

| Brand Name: | Torich |

| Model Number: | ASTM A106 |

| Certification: | ISO 9001-2008 ISO 14001 TS 16949 DNV LR |

| Place of Origin: | China |

| MOQ: | 0.5 Ton/Tons |

| Price: | negotiable |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 60000 Tons per Year |

| Delivery Time: | 30-45 Days |

| Packaging Details: | oil antirust In hexagonal bundles |

| Product Name: | ASTM A106 Seamless Carbon Steel Pipe for High-Temperature Service |

| Type: | Seamless Steel Tubes |

| Surface: | Black Painted |

| Material: | 10#.20#.16Mn.A106(B,C).ST35-ST52 |

| Length: | 1-12m Or As Your Request |

| OD: | 6-1000mm |

| WT: | 1-80mm |

| Shape: | Round |

| Company Info. |

| TORICH INTERNATIONAL LIMITED |

| Verified Supplier |

| View Contact Details |

| Product List |

ASTM A106 Seamless Carbon Steel Pipe for High-Temperature Service

This covers seamless carbon steel pipe forhigh-temperature service in NPS !/8 to NPS 48 [DN 6 ItoDN 1200] inclusive, with nominal (average) wallthickness as given in ASME B 36.10M. It shall be permissibleto furnish pipe having other dimensions provided such pipecomplies with all other requirements of this specification. Pipeordered under this specification shall be suitable for bending,flanging, and similar forming operations, and for welding.When the steel is to be welded, it is presupposed that a weldingprocedure suitable to the grade of steel and intended use Orservice will be utilized.

Size: Outer Diameter: 6-1000 mm,Wall Thickness: 1- 80 mm,Length :1-12m or as your request

Application:High-Temperature Service

Material:10#.20#.16Mn.A106(B,C).ST35-ST52

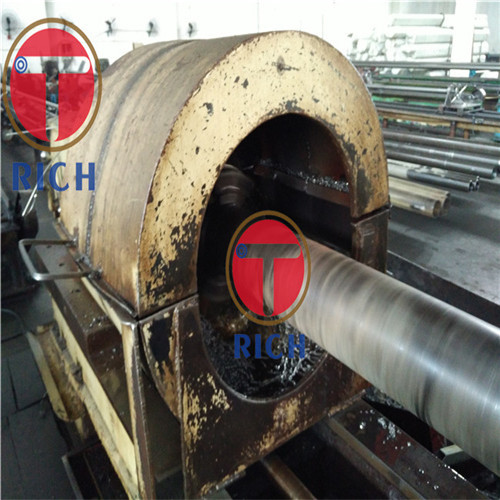

Manufacture :Tubes shall be made by the seamless process and shall be cold drawn.

Heat Treatment:

1)Cold-drawn tubes shall be heat treated after the finalcold-draw pass at a temperature of 1 200F [640C] or higher toensure ductility satis factory for rolling into tube sheets and tomeet mechanical properties as specified.

2)If stress -relief anneal of the U-bends is specified, theanneal shall consist of heating the bent portion within a rangeof 1100 to 1200F [585 to 640C].

Outside diameter and wall thickness allow deviation mm

| sort code | Manufacturing method | Steel tube size | Allowable deviation | |

WHR (WHEX) | Hot rolled(extruded)steel tube | OD | all | ±1%Dor±0.50(choose the bigger) |

| WT | ≤20 | -15% +0.45 -10%S or –0.30 (choose the bigger) | ||

| >20 | ±10%S | |||

| WHE | Heat expand steel tube | OD | all | ±1%D |

| WT | all | ±15%S | ||

WCD (WCR) | Cold drawn(rolled) steel tube | OD | ≤30 | ±0.20 |

| 30<D≤50 | ±0.30 | |||

| >50 | ±0.8%D | |||

| WT | 1.5≤S≤3 | +12.5% -10% S | ||

| >3 | ±10%S | |||

Bending of steel tube per meter

| OD/mm | Bending per meter(mm/m) |

| ≤15 | ≤1.5 |

| >15~30 | ≤2.0 |

| >30 or D≥351 | ≤3.0 |

The length of the steel tube bending should be not more than 1.5% of the steel tube length

|