| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Digital Parts |

|---|---|

| Brand Name: | OEM/ODM |

| Model Number: | HW-017 |

| Certification: | ISO9001 |

| Place of Origin: | China |

| MOQ: | 1000 pieces |

| Price: | negotiable |

| Payment Terms: | T/T, L/C |

| Supply Ability: | 15000 pieces per month |

| Delivery Time: | 15-30days |

| Packaging Details: | PE bag , as customer requested |

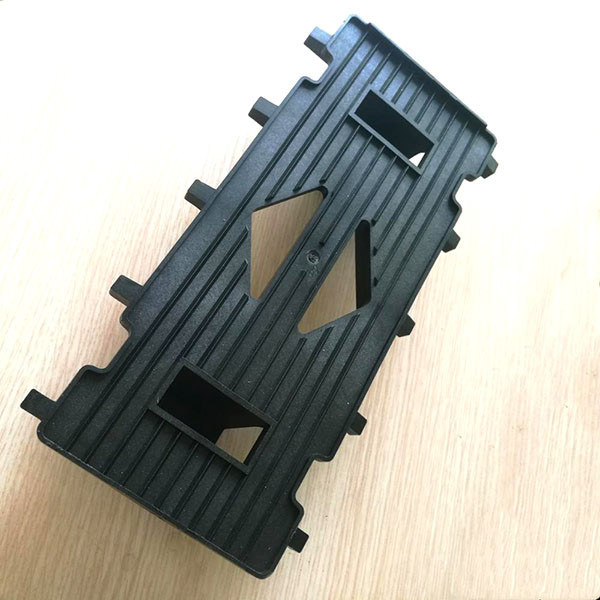

| Plastic mould: | Home appliance plastic printer injection mould/mold maker/molding parts |

| Specification checking: | Caliper, Quick checking tools |

| Mould Type: | Injection Plastic Mould |

| Surfce Treatment: | Texture Polishing |

| plastic material: | HIPS ABS, PC, PP, PS |

| Tool Material: | 1.2738H |

| Runner: | Cold Runner |

| Gate Type: | Pin Point Gate |

| Mould standard: | Hasco, DME |

| Mould cavity: | single cavity |

Home appliance plastic printer injection mould/mold maker/molding parts

Mould Information:

| Type of mould | Injection mould Small, medium, large mold |

| Mold Material | S136, SKD61,H13,SKD11, NAK80, 2738,718,etc, High hardness alloy steel with heat treatment, wear resistance, corrosion resistance. |

| Mold Cavity | Single-cavity or Multi-cavity, as per customers requirement and part structure |

| Cycle Time | 10-300 seconds, according to the products, cavity, and equipment |

| Injection Equipment | Injection machines from 15T to 1200T--56 sets |

| Mold Life | 300,000 shots, 1,000,000 shots |

| Product Material | Normal Plastic: PP,PE,EVA,PS; Engineering Plastic: PA,PA6,PA66,PC+ABS,PA46,PA+60%GF,PC,ABS,POM, PBT; High Engineering Plastic: PEEK, PPS, PPO, PEI, PES, LCP, antistatic plastic, etc. |

| Injection Type | Hot runner, Cold runner, as customers' requirement and part structure. |

| Software | UG, Proe, Solidworks, Autocad, etc. |

| Main Processing Equipment | CNC, Slow Wire, EDM, CNC lathe, precision grinder, milling machine, driller, wire cutting machine, etc |

| Surface Finish | Tech polish, High gloss, Texture, Printing, Painting, Plating |

| Product Color | White, black, red, yellow, blue, green, as per your requirement |

| Equipment | Manufacturer | Specification | Number |

| Injection Molding Machine | FANUC | 15-ton | 1 |

| Injection Molding Machine | Nissei | 20-ton | 13 |

| Injection Molding Machine | Nissei | 40-ton | 2 |

| Injection Molding Machine | Kawaguchi Tetsuku | 140-ton | 2 |

| Injection Molding Machine | Kawaguchi Tetsuku | 180-ton | 1 |

| Injection Molding Machine | Kawaguchi Tetsuku | 280-ton | 4 |

| Process of making moulds | |

| 1.Sample/Drawing | After receiving your detail information like 2D & 3D drawings or sample for reference, will pass to the R&D team to do Moldflow analysis. |

| 2.Negotiation | Material, cavity, price, delivery time, payment term etc. |

| 3.Place Order | when all terms are agreed by both sides, then we will accept an order. |

| 4.Mould Design | Our R&D team will design the mould per customer requirements and send drawings for approval. |

| 5.Tooling Mould | Once the mould design is approved will start mould tooling. |

| 6.Mould Process | CNC grinding and milling, Heat Treatment, Wire Cut, Polish, Tool assembling and testing etc. Our good QC system can guarantee the product quality. |

| 7.Sample Confirmation | Send samples for confirmation, if not approved we will adjust the mould structure. |

| 8.Mass Production | After the customer approves the sample, we will arrange mass production. QC will inspect after products finished. |

| 9.Package | PE film for plastic parts, wooden case for moulds or as customer's requirement. QC will inspect packing. |

| 10.Delivery | By sea or by air according to customer requirement. |

| 11.After-sales Service | Ready to help customers solve any possible problems. |

| Item Name | Expert of Precision Injection Plastic Tooling Design and Mold Maker |

| Service | 1.CNC Plastic/Metal Prototypes |

| 2.Vacuum casting/vacuum forming(Silicon Mould) | |

| 3.Low Volume Production | |

| 4.Rapid Hardware/Sheet Metal Prototypes | |

| 5.CNC Aluminum/Brass/Copper/Bronze CNC machining/machined parts | |

| 6.Automotive and medical equipment Prototypes | |

| 7.SLA/SLS prototype | |

| 8.Metal Stamping&NCT Stamping | |

| 9.3D Printing | |

| 10.Die-casting, hardware machining | |

| 11.Electronic Manufacturing Service | |

| 12.Injection mould&Plastic Injection | |

| 13. Lathing parts | |

| 14.Design service (OEM service) | |

| Certification passed | Bureau Veritas, ROHS, ISO |

1. What is your business?

A. Precision Plastic Mold manufacture

B. Medium and large plastic mold manufacture

C. Injection molding

D. professional designing and making

E. R&D service

2. How about tolerance?

Mold tolerance is 0.005 mm, Product tolerance is 0.02 mm.

3. What steel do you usually use?

We usually use steel of P20, P20H, H-13,O-1,S-7,420,420H,D2, NAK80,

1.2311, 1.2711,1.2344,1.2510,1.2083,1.2316 and 1.2379.

4. What standard components do you usually use?

We use standard components from LKM, DAIDO, HASCO, DME. (Hot

Runner: MOLD MASTER, HUSKY, DME, HASCO, INCOE, THERMOPLAY, YUDO.)

5. What do you need for a quotation?

We need 2D part drawing & 3D drawing, and specific mold or part

requirements.

2D File Format dwg /dxf /pdf/jpg ,3D Model Format step /x_t /igs

/prt

6.How about your mold payment terms?

Mold payment terms:40%-30%-30%.The first payment is when you sign

the order, you should pay us 40% of the total value; the second

payment is when you receive our sample product, you should pay us

30% of the total value; the last payment is when we deliver the

mold for you, you should pay off the balance payment,30% of the

total value.

7. How about your part payment terms?

Part payment terms:50%-50%.The first payment is when you sign the

order, you should pay us 50% of the total value to purchase the

material; The last payment is when we deliver the part for you, you

should pay off the balance payment,50% of the total value.

8. What’s your after-sales?

After-sales: Our customer’s mold drawings and the whole data will

be kept in a database for 5 years at least.so that when you need

our technical support or service, we can be easy and possible to

serve you and your customers.

|