| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Alloy Steel Pipe |

|---|---|

| Brand Name: | Torich |

| Model Number: | C10200 B75 |

| Certification: | ISO 9001 ISO14001 TS16949 |

| Place of Origin: | China |

| MOQ: | 200 pcs |

| Price: | negotiable |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 20000 Ton per Year |

| Delivery Time: | 30-45 days after order confirmed |

| Packaging Details: | In plywood case, In wooden box. |

| Characteristic: | Low Fin Tube |

| Material: | C10200, C11000 etc |

| Production Method: | Seamless |

| Package: | In bundles or as per requests |

| Finish: | Annealed |

| Length: | 1-12m |

| Type: | Copper Low Fin Tube |

| MTC: | EN10204.3.1 |

| Company Info. |

| TORICH INTERNATIONAL LIMITED |

| Verified Supplier |

| View Contact Details |

| Product List |

Products Description:

for Heat Exchanger Seamless Copper Low Fin Tube C10200 B75

Quick Detail:

Low-finned tubes are a reliable solution for controlling the temperature of gases and liquids, or for evaporating and condensing refrigerants. Thanks to their larger heat transfer surface area, they offer considerable potential to save in terms of materials and fill volumes.

Size:

| Plain tube (mm) | Finned section dimensions (mm) | Ratio | De | |||

| D×t | Tp | dd | dr | di | η | mm |

| 19×2 | 0.8 | 18.8 | 17 | 134 | 2.8 | 17.9 |

| 19×2 | 1 | 18.8 | 16.8 | 13.4 | 2.5 | 17.8 |

| 19×2 | 1.25 | 18.8 | 16.6 | 13 | 2.2 | 17.8 |

| 19×2 | 1.5 | 18.8 | 16.6 | 13 | 2 | 17.7 |

| 19×2 | 2 | 18.8 | 16.4 | 13 | 1.7 | 17.5 |

| 25×2.5 | 0.8 | 24.8 | 23 | 18.8 | 2.8 | 23.9 |

| 25×2.5 | 1 | 24.8 | 22.6 | 18.8 | 2.75 | 23.7 |

| 25×2.5 | 1.25 | 24.8 | 22.3 | 18 | 2.5 | 23.6 |

| 25×2.5 | 1.5 | 24.8 | 22.3 | 18 | 2.2 | 23.5 |

| 25×2.5 | 2 | 24.8 | 22 | 18 | 1.8 | 23.4 |

| 25×2.5 | 2.5 | 24.8 | 22 | 18 | 1.6 | 23.3 |

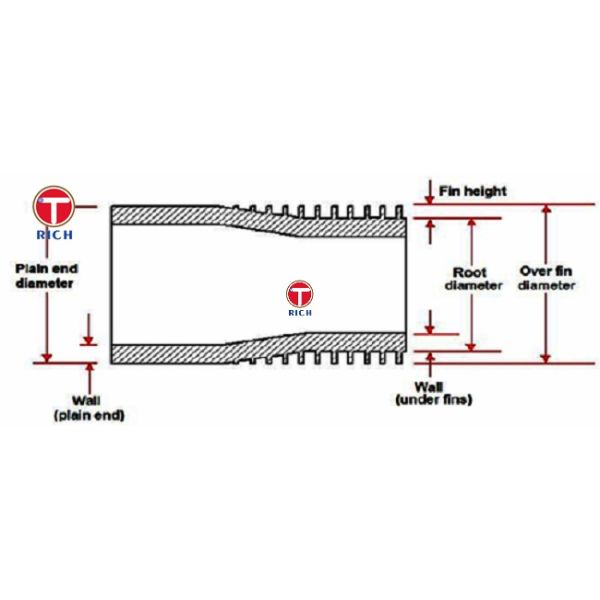

| D------Outside diameter of plain end section Dof----Diameter of top fins Dr-----Root diameter of finned section Di-----Inside diameter of finned section T------Wall thickness of plain end section Tp-----Fin pitch De----Equivalent diameter of finned tube L------Plain tube end length | ||||||

Applications: Heat Exchanger Tube

The Benefits:

1. Offers 2.5-3 times the external surface area of bare tube

2. Enhanced heat exchanger efficiency means less tube is required to accomplish the same heat transfer as a bare tube

3. Low finned tube can increase the performance of an existing exchanger without the difficult and expensive task of building new shells etc

4. Reduced space and weight can be extremely valuable in offshore production or high elevation distillation columns. Low finned technology can transform large shell and tube exchangers into compact heat exchangers

Production Steel Tube:

Application:

|