| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | High Carbon Alloy Steel |

|---|---|

| Brand Name: | CF Steel |

| Model Number: | 1.2312 / P20+S / 3Cr2Mo+S |

| Certification: | ISO / Mill Certificate |

| Place of Origin: | China |

| MOQ: | Negotiable |

| Price: | Negotiable |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 1000 t/month |

| Delivery Time: | 10-15 days |

| Packaging Details: | Export Standard Packing or Customers'demand |

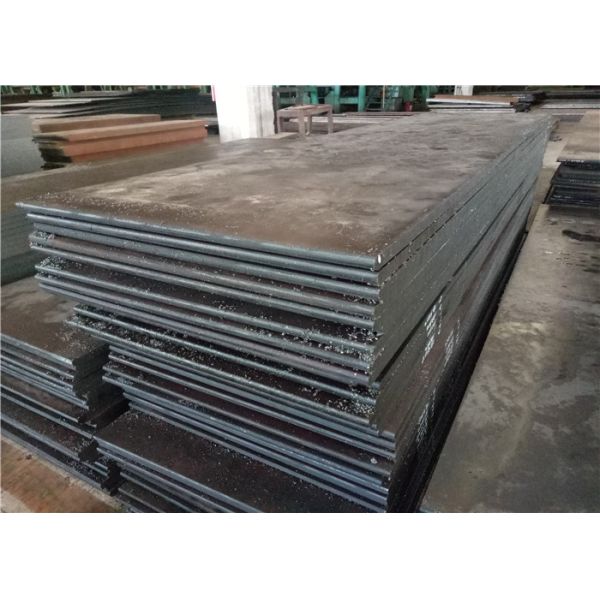

| Shape: | Steel plate / Round bar / Flat bar |

| Grade: | 1.2312 / P20+S / 3Cr2Mo+S |

| Surface treatment: | Polished / Black |

| Heat treatment: | Annealed / Q+T |

| Service: | Sample free and 24 hours online |

| Payment Term: | 30% Deposit, Balance by L/C at Sigth After Shipment |

High Carbon Alloy Steel Plate 1.2312 / P20+S Plastic Mould Steel

Equivalent grades:

| GB | DIN | AISI | JIS |

| 3Cr2Mo+S | 1.2312 | P20+S | PX5 |

Introduction:

High carbon alloy steel plate 1.2312 / P20+S plastic mould steel is

a widely used plastic die steel in the world, as well as its

comprehensive mechanical performance is good. It has high

hardenability, and can makes large section steel earn a relatively

uniform hardness, also it has good polishing performance.

Chemical Composition(%):

| C | Si | Mn | Cr | P | S | Mo |

| 0.35-0.45 | 0.35-0.50 | 1.40-1.60 | 1.80-2.00 | ≤0.035 | ≤0.015 | 0.30-0.55 |

Feature:

Plastic mould steel with excellent machinability properties because

of the high S content, good toughness properties, good dimensional

stability, requiring no heat treatment, 280-325HB hardened and

tempered condition, suitable for nitriding to increase

wear-resistance, not suitable for chrome plating to increase

wear-resistance, not suitable for chrome plating and polishing.

Recommend heat treatment:

| Quenching | Tempering | ||||

| Heating temperature/℃ | Cooling way | Hardness (HRC) | Tempering temperature /ºC | Cooling way | Hardness (HRC) |

| 870-890 | Oil Cooling | 50-54 | 550-640 | Air Cooling | 28-36 |

Applications:

For the production of plastic molds and casting low melting metal

material. This steel has good machinability and mirror grinding

performance.

Delivery condition:

Hot rolled or forged, black surface.

Hardenss: pre-hardening or tempering to 28-33HRC.

| Hot sale products for hot/cold work mould Steel | |||||||||

| STANDARD/GRADE | Flat Bar Size(mm) | Round bar Size(mm) | Technics | ||||||

| DIN | AISM | JIS | GB(China) | Thickness | Width | Length | Diameter | Length | |

| 1.2311 | P20 | PDS-3 | 3Cr2Mo | 10-700 | 155-2200 | 2000-6000 | 20-200 | 2000-6000 | Forged, Hot Rolled |

| 1.2738 | P20+Ni | - | 3Cr2NiMnMo | 10-1100 | 155-2200 | 2000-6000 | 20-200 | 2000-6000 | |

| 1.2379 | D2 | SKD10 | SKD10 | 10-200 | 155-810 | 2000-6000 | 20-200 | 3000-6000 | |

| 1.2080 | D3 | SKD1 | 3Cr2Mo | 10-200 | 155-810 | 2000-6000 | 20-200 | 3000-6000 | |

| 1.2083 | 420 | - | 4Cr13 | 10-500 | 155-1200 | 2000-6000 | 20-300 | 3000-6000 | |

| 1.2344 | H13 | SKD61 | 4Cr5MoSiV1 | 10-500 | 155-1600 | 2000-6000 | 20-400 | 3000-6000 | |

| 1.2510 | O1 | SKS3 | 9CrWMn | 10-200 | 155-810 | 2000-6000 | 20-200 | 3000-6000 | |

| 1.7225 | SAE4140 | SCM440 | 42CrMo | 10-200 | 155-2200 | 2000-6000 | 20-200 | 3000-6000 | |

| 1.2010 | SAE1050 | S50C | 50# | 10-700 | 155-2200 | 3000-6000 | 10-300 | 3000-6000 | Hot Rolled |

| 1.1191 | SAE1045 | S45C | 45# | 10-700 | 155-2200 | 3000-6000 | 10-300 | 3000-6000 | |

|