| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Alumina Ceramic Rod |

|---|---|

| Brand Name: | Custom |

| Model Number: | Customer's requirment |

| Certification: | ISO2008, ROHS |

| Place of Origin: | Guangdong, China(mainland) |

| MOQ: | 5 PCS |

| Price: | Negotiable |

| Payment Terms: | T/T, Western Union, Paypal |

| Supply Ability: | 3000 pcs per month |

| Delivery Time: | 15-30 working days after receiving deposit |

| Packaging Details: | Hollow Alumina Ceramic Rod / Tube will be packed in PP bag or sponge tray, then put in standard export carton packing, or OEM packing. |

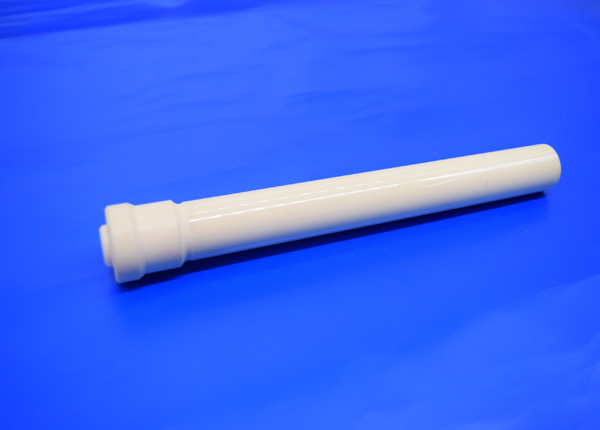

| Product name: | Hollow Alumina Ceramic Rod / Tube |

| Material: | Zirconia / alumina ceramic |

| HV Hardness: | 1300 - 1650 Mpa |

| Flexural Strength @ Room Temperature: | 280 Mpa ( 95 alumina ), 310 Mpa ( 99 alumina ), 950 Mpa ( zirconia ) |

| Compressive Strength@Room Temperature: | 2000 - 2200 Mpa |

| Fracture Toughness: | 3.8 Mpa * m½ ( 95 alumina ), 4.2 Mpa * m½ ( 99 alumina ), 10 Mpa * m½ ( zirconia ) |

| Heat Conductivity @ Room Temperature: | W / m * k / 18 - 25 ( 95 alumina ), 26 - 30 ( 99 alumina ), 2.0 - 2.2 ( zirconia ) |

| Max Application Temperature: | ℃ / 1500 ( 95 alumina ), 1750 ( 99 alumina ), 1050 ( zirconia ) |

| Color and size: | White, ivory, customized |

| Application: | Industrial alumina ceramic rod / tube parts |

Polished Hollow Alumina Ceramic Rod / Tube OD 12mm Al2O3 99.5 %

with Superior Mechanical Strength

Product Description

Advantages of Hollow Alumina Ceramic Rod / Tube:

1. Refractory.

2. Isostatic Pressed.

3. Long Service Life.

4. Superior Mechanical Strength.

5. High Corrosion and Wear Resistance.

6. Good Insulation Performance Precision.

7. High Temperature and Pressure Resistance.

8. High Purity Zirconia and Alumina Ceramic Material.

They are high corrosion and wear resistance and strong impact

resistance and delivers 10 times longer working life than metal rod

/ tube. They give a longer life to the sealed packing material.

Dimension and tolerance:

·Diameter as small as 0.2mm, depends on length

·Length as long as 550mm, as short as 0.5mm

·Diameter tolerance we could make as fine as 0.001mm

The length and special sizes can be customized, As per 100% drawing

Data Sheet of Product

| Properties | Unit | Alumina | Zirconia | ||||

| 96%Al2O3 | 99%Al2O3 | 99.5%Al2O3 | 99.8%Al2O3 | 99.9%Al2O3 | 3Y-TZP | ||

| Colour | - | White | White | Ivory | Ivory | Translucent | white/black |

| Bulk density | g/cc | 3.78 | 3.88 | 3.93 | 3.93 | 3.98 | 6.03 |

| Water Absorption | % | 0 | 0 | 0 | 0 | 0 | 0 |

| Grain size | μm | 5-10 | 2-5 | 2-5 | 2-5 | 2-4 | 0.4 |

| Bending strength | MPa | 380 | 350 | 360 | 380 | 300 | 1000 |

| KIC | MPa.m1/2 | 3~4 | 4 | 3~4 | 3~4 | 3~4 | 5~8 |

| Vickers Hardness | GPa | 13 | 14 | 14.5 | 14.5 | 15 | 13 |

| Young's Modulus of Elasticity | GPa | 360 | 370 | 370 | 380 | 390 | 200 |

| Thermal Conductivity | W/m° K | 24 | 28 | 32 | 32 | 34 | 2 |

| Coefficient of Linear Expansion | 10-6/°C | 6.7 | 7.2 | 7.2 | 7.2 | 7.2 | 10.5 |

| Dielectric Constant (1MHz) | - | 9.1 | 9.5 | 9.6 | 9.6 | 9.9 | 33 |

| Dielectric Loss Angle (1MHz) | - | 0.0002 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.002 |

| Dielectric Strength | V/m | 15×106 | 15×106 | 15×106 | 15×106 | 15×106 | 11×106 |

| Volume Resistivity | Ohm.cm | >1014 | >1014 | >1014 | >1014 | >1014 | 1013 |

| (RT) | |||||||

Produce and machining

We can produce different sizes and shapes of the rod for specific applications to different custom products.Such as drilling, polishing, stripes, concave and convex, screw holes, metal parts position and so on

1. Can Be Custom By Drawing Or The Parameter

2.Can Be Offer a Samples Within 1--10 Qty

3. The Shipping Time Of The Samples Within 2days

4. Quick Delivery Via Fedex,Dhl,Ups,Tnt Etc.

For more informations (the price,payment etc), Please contact us or email: admin@cerampart.com

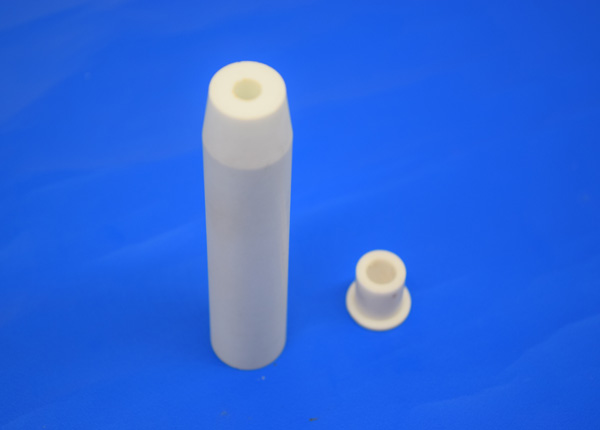

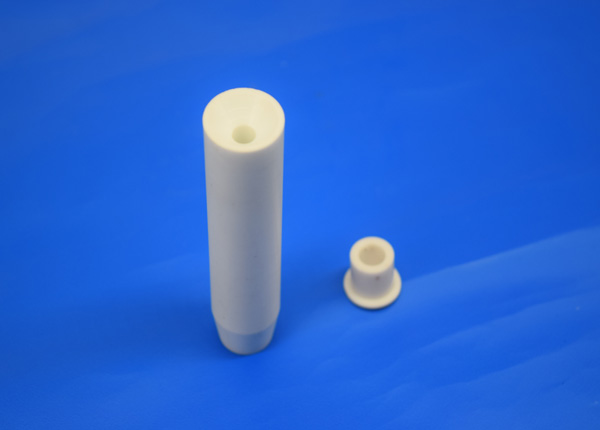

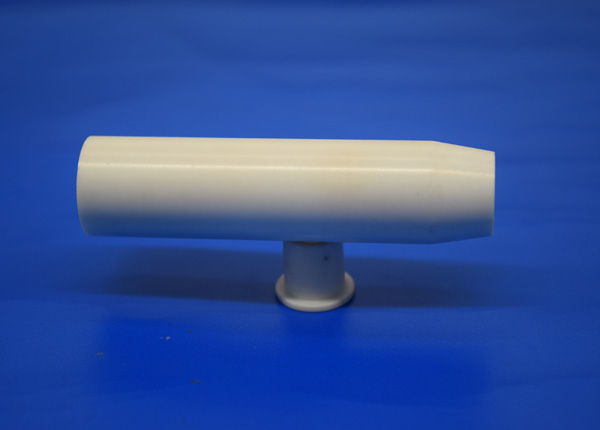

Detailed Images

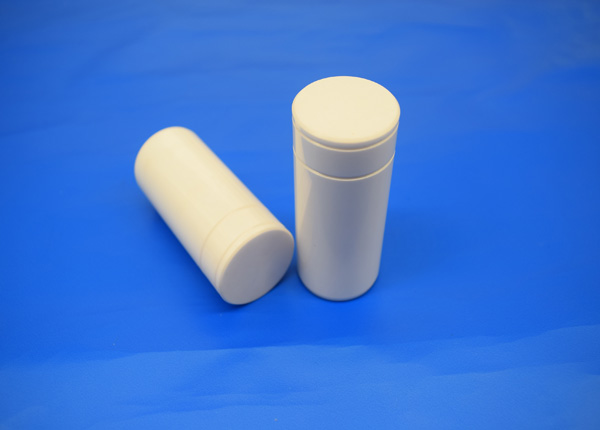

Related Products

Packaging and Shipping

Hollow Alumina Ceramic Rod / Tube will be packed in PP bag or

sponge tray, then put in standard export carton packing, or OEM

packing.

Shipped by Air ( DHL, TNT, UPS, Fedex, EMS ), or Sea

transportation.

Company information

Who Are We?

Mingrui is a professional factory with years OEM experience in manufacturing industrial ceramic

parts.

What Do We Do?

We produce (OEM ) strengthened structure zirconia and alumina ceramic rod, ring, tube, shaft, plate, sleeve,

bushing, washer, valve, plunger, pin, nozzle and ceramic arm, etc., they are applicable to instruments, medical instruments,

clocks and electronic products, mills, energy and power, machine

and metals, autocar and military, spaceflight and some other

high-end fields.

All of our products with certificates, such as , CE, TUV, etc..

Factory Show

Production Process Show

One-stop production, from the raw material to final product.

|