| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Stainless Steel Plate |

|---|---|

| Brand Name: | HT |

| Model Number: | Hot sale UNS S32750 Duplex stainless steel 2507 plate sheet China supply |

| Certification: | ISO,BV,SGS |

| Place of Origin: | China,USA,GERMANY,JAPAN |

| MOQ: | 100kg |

| Price: | Negotiation |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 100kg per month |

| Delivery Time: | 3-50 days |

| Packaging Details: | steel frame or as per the clients' request |

| Type: | Plate, Sheet,Strip, Coil |

| Length: | 0~12m or as per the client's requirements |

| Width: | 0~2500mm or as per the client's requirements |

| Thickness: | 0.3~1200mm or as per the client's requirements |

| Process: | Hot/Cold Rolled |

| Surface: | No.1 No.2D No.2B BA No.3 No.4 No.6 No.7 |

| Packing: | Steel Frame, waterproof paper, wooden pallet, wooden case or as per the client's requirements |

| Origin: | USA, GERMANY,JAPAN,China |

Hot sale UNS S32750 Duplex stainless steel 2507 plate sheet China supply

2507 (UNS S32750) is a super duplex stainless steel designed for applications which require exceptional strength and corrosion resistance. 2507 is a 25% chromium, 4% molybdenum, and 7% nickel alloy resulting in excellent resistance to chloride pitting and crevice corrosion attack. The duplex structure provides 2507 with exceptional resistance to pitting and chloride stress corrosion cracking.

Usage of 2507 should be limited to applications below 600° F (316° C). Extended exposure to elevated temperatures can reduce its toughness and corrosion resistance.

Inventory

2507 Fittings, 2507 Flanges, 2507 Pipe, 2507 Plate, 2507 Round Bar, 2507 Sheet

General Corrosion

The high chromium and molybdenum content of 2507 makes it extremely

resistant to uniform corrosion by organic acids like formic and

acetic acid. 2507 also provides excellent resistance to inorganic

acids, especially those containing chlorides.

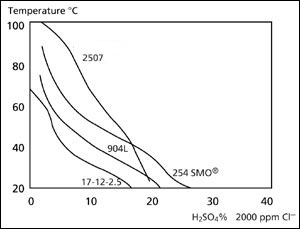

In dilute sulfuric acid contaminated with chloride ions, 2507 has better corrosion resistance than 904L, which is a highly alloyed austenitic steel grade specially designed to resist pure sulfuric acid.

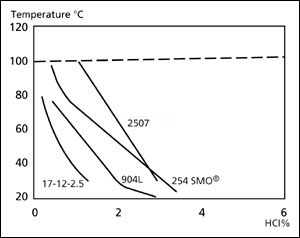

Stainless steel of type 316L (2.5%Mo) cannot be used in hydrochloric acid due to the risk of localized and uniform corrosion. However, 2507 can be used in dilute hydrochloric acid. Pitting need not be a risk in the zone below the borderline in this figure, but crevices must be avoided.

Isocorrosion curves, 0.1 mm/year, in sulfuric acid with an addition of 2000 ppm chloride ions

Isocorrosion curves, 0.1 mm/year, in hydrochloric acid. Broken line curve represents the boiling point

Critical Pitting Temperature (CPT) range for various alloys in 1M NACl

Critical Crevice Corrosion Temperature (CCT)for various alloys in 10% FeCl3

Intergranural Corrosion

2507's low carbon content greatly lowers the risk of carbide

precipitation at the grain boundaries during heat treatment;

therefore, the alloy is highly resistant to carbide-related

intergranular corrosion.

Stress Corrosion Cracking

The duplex structure of 2507 provides excellent resistance to

chloride stress corrosion cracking (SCC). Because of its higher

alloy content, 2507 is superior to 2205 in corrosion resistance and

strength. 2507 is especially useful in offshore oil and gas

applications and in wells with either naturally high brine levels

or where brine has been injected to enhance recovery.

Pitting Corrosion

Different testing methods can be used to establish the pitting

resistance of steels in chloride-containing solutions. The data

above were measured by an electrochemical technique based on ASTM G

61. The critical pitting temperatures (CPT) of several

high-performance steels in a 1M sodium chloride solution were

determined. The results illustrate the excellent resistance of 2507

to pitting corrosion. The normal data spread for each grade is

indicated by the dark gray portion of the bar.

Crevice Corrosion

The presence of crevices, almost unavoidable in practical

constructions and operations, makes stainless steels more

susceptable to corrosion in chloride enviroments. 2507 is highly

resistant to crevice corrosion. The critical crevice corrosion

temperatures of 2507 and several other high-performance stainless

steels are shown above.

|