| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Magnesia Refractory Bricks |

|---|---|

| Brand Name: | ZHENGHZOUXINYU |

| Model Number: | BDMGe-16/18/20/24 |

| Certification: | GB/T19001-2016/ISO9001:2005 |

| Place of Origin: | ZHENGZHOUGONGYI |

| MOQ: | 2T |

| Price: | 1170USD~1670USD/T |

| Payment Terms: | L/C, , T/T, D/P, Western Union, MoneyGram |

| Supply Ability: | 1000T/25D |

| Delivery Time: | 5-8work |

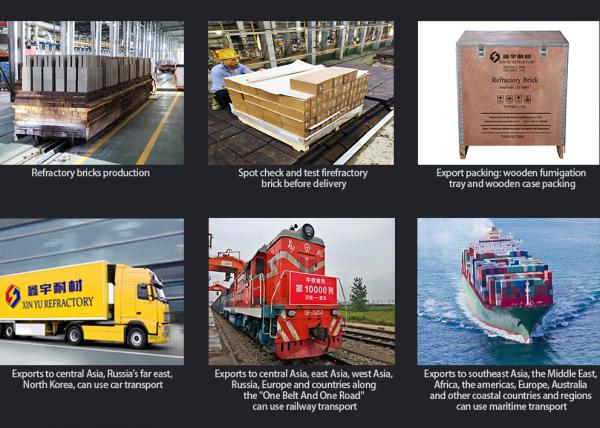

| Packaging Details: | packed on wooden pallets, with water-proof cover, and tightened with plastic/steel bandages |

| Mgo content(%): | ≥16/18/20/24/80 |

| Bulk density: | ≥3.15/cm3 |

| Refractoriness(degree): | 1850℃<Refractoriness<2000℃ |

| Shape: | Brick,Block |

| Material: | square magnesite, magnesia-chrome spinel |

| Size: | according to customer 's requirements |

| Crushing strength/ MPa,≥: | 50 |

| Apparent porosity,≤: | 15/16 |

| Cr2O3 content(%)≥: | 24/20/18/16 |

Electrofused semi - recombined magnesia - chrome brick/Used for steel smelting, refining ladle/VOD furnace/AOD furnace

Product description:

Magnesia-chrome brick made by electrofused magnesia-chrome sand as raw material is called recombined magnesia-chrome brick, and the product with partial electrofused magnesia-chrome sand is called semi-recombined magnesia-chrome brick.

Category of Refractory Brick/Fire Brick:

Magnesia-chrome brick is divided into ordinary magnesia-chrome brick, directly combined magnesia-chrome brick, electrofused semi-recombined magnesia-chrome brick and electro fused magnesia-chrome brick.

Features:

Accordi According to the characteristics of microstructure high temperature crystal phase direct bonding, recombined and semi-recombined magnesia-chrome bricks are the direct bonding bricks with higher direct bonding rate.They are characterized by high strength, erosion resistance, erosion resist -ance, spalling resistance, good slag resistance and thermal shock stability.Mainly used for smelting nonferrous metals, pierrey-smith, Noranda, Ausmelt, Flash famace, electric steelmaking furnace, converter, VOD furnace, refining ladle, etc.The recombined magnesia-chrome brick is more suitable for the high erosion area of the furnace than the semi-combined magnesia-chrome brick.

Physical and chemical indicators:

| Brand | Electrofused semi-recombined magnesia-chrome brick | |||||

|---|---|---|---|---|---|---|

| XY-BDMGe-24 | XY-BDMGe-20 | XY-BDMGe-18 | XY-BDMGe-16 | |||

| MgO | 52 | 60 | 62 | 65 | ||

| Cr2O3 | 24 | 20 | 18 | 16 | ||

| CaO | 1.5 | 1.5 | 1.5 | 1.5 | ||

| Fe2O3 | 9.0 | 9.0 | 8.0 | 8.0 | ||

| SiO2 | 1.2 | 1.2 | 1.2 | 1.5 | ||

| AL2O3 | 8.0 | 8.0 | 8.0 | 7.0 | ||

| Apparent porosity,≤ | 15 | 15 | 16 | 16 | ||

| Bulk density/g﹒cm-3,≥ | 3.15 | 3.15 | 3.15 | 3.15 | ||

| Crushing strength/ MPa,≥ | 50 | 50 | 50 | 50 | ||

| Refractoriness under load,0.2MPa,℃(≥) | 1700 | 1700 | 1700 | 1700 | ||

1100℃ Cair cooling,blowing Themal shock resistanc | 4 | 4 | 4 | 4 | ||

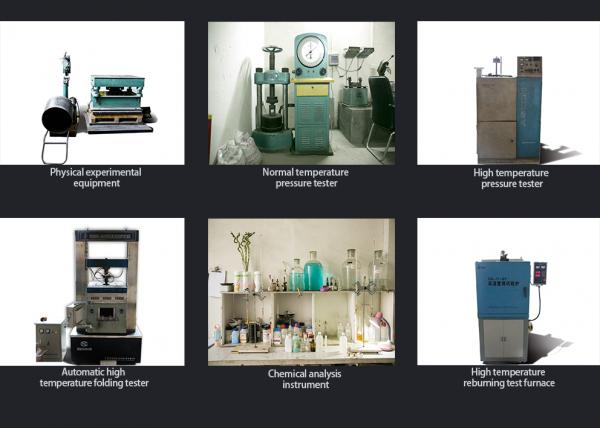

Production and inspection :

Packaging and transportation:

|