| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

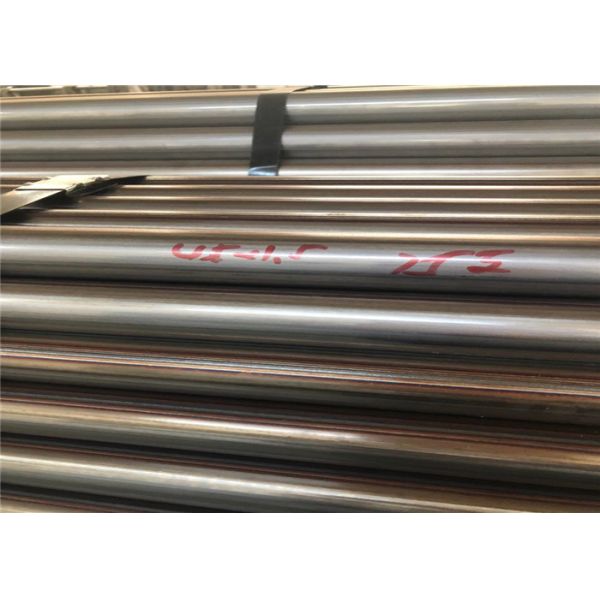

| Categories | Ss Stainless Steel Welded Tubing |

|---|---|

| Brand Name: | HDT |

| Model Number: | TP304 TP304L TP316 TP316L |

| Certification: | ASME, TUV, SGS, ABS, PED, ISO9001, Grade A |

| Place of Origin: | China(Mainland) |

| MOQ: | 5T |

| Price: | 800 - 9000 USD / ton |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | About 10000 ton / month |

| Delivery Time: | 60-75days |

| Packaging Details: | seaworthy packing for exporting |

| Material: | TP304 TP304L TP316 TP316L |

| Finishing: | Solution Annealed & Pickled |

| Application: | boiler&heat exchanger, energy, petrochemical, mining, food, paper, gas and fluid industry |

| Shape: | Welded Tube |

| OD: | 15.9mm to 406.4mm |

| WT: | 0.89mm to 5mm |

| Company Info. |

| ZHANGJIAGANG HUA DONG ENERGY TECHNOLOGY CO.,LTD |

| Verified Supplier |

| View Contact Details |

| Product List |

Production

| Stainless Steel Mechanical Properties | ||||||

| Grade | Tensile Strength | Yide Strength | Elogation | Hardness | Solution Annealing | |

| kgf/mm²(N/mm²) | kgf/mm²(N/mm²) | % | HRB(HV) | ℃ | ||

| ASTM | TP 304 | ≥53 (515) | ≥21 (205) | ≥35 | ≤90 (200) | 1040℃-1150℃ Water Quenching |

| TP 304L | ≥50 (485) | ≥17 (170) | ||||

| TP 316 | ≥53 (515) | ≥21 (205) | ||||

| TP 316L | ≥50 (485) | ≥17 (170) | ||||

| JIS | SUS 304 | ≥53 (520) | ≥21 (205) | 1010℃-1150℃ Water Quenching | ||

| SUS 304L | ≥49 (480) | ≥18 (175) | ||||

| SUS 316 | ≥53 (520) | ≥21 (205) | ||||

| SUS 316L | ≥49 (480) | ≥18 (175) | ||||

| GB | 06Cr19Ni10 | ≥53 (520) | ≥21 (210) | 1010℃-1150℃ Water Quenching | ||

| 022Cr19Ni10 | ≥49 (480) | ≥18 (180) | ||||

| 06Cr17Ni12Mo2 | ≥53 (520) | ≥21 (210) | ||||

| 022Cr17Ni12Mo2 | ≥59 (480) | ≥18 (180) | ||||

| EN | 1.4301 | (500-700) | ≥20 (195) | ≥40 | 1000℃-1100℃ Water Quenching | |

| 1.4307 | (470-670) | ≥18 (180) | ||||

| 1.4401 | (510-710) | ≥21 (205) | 1020℃-1120℃ Water Quenching | |||

| 1.4404 | (490-690) | ≥19 (195) | ||||

| Size OD | Nominal Wall | Outside Diameter | Length | Wall |

| 1/2" (12.7) | 0.065" (1.65)/0.049" (1.25) | +/-0.005 (0.13) | +1/8" (3.18) - 0 | +/-10.0% |

| 3/4" (19.1) | 0.065" (1.65)/0.049" (1.25) | +/-0.005 (0.13) | +1/8" (3.18) - 0 | +/-10.0% |

| 1" (25.4) | 0.065" (1.65)/0.049" (1.25) | +/-0.005 (0.13) | +1/8" (3.18) - 0 | +/-10.0% |

| 1-1/2" (38.1) | 0.065" (1.65)/0.049" (1.25) | +/-0.008" (0.20) | +1/8" (3.18) - 0 | +/-10.0% |

| 2" (50.8) | 0.065" (1.65)/0.049" (1.25) | +/-0.008" (0.20) | +1/8" (3.18) - 0 | +/-10.0% |

| 2-1/2" (63.5) | 0.065" (1.65) | +/-0.010" (0.25) | +1/8" (3.18) - 0 | +/-10.0% |

| 3" (76.2) | 0.065" (1.65) | +/-0.010" (0.25) | +1/8" (3.18) - 0 | +/-10.0% |

| 4" (101.6) | 0.083" (2.11) | +/-0.015" (0.38) | +1/8" (3.18) - 0 | +/-10.0% |

| 6" (152.4) | 0.083" (2.11) | +/-0.030" (0.76) | +1" (25.4) - 0 | +/-10.0% |

| 6" (152.4) | 0.109" (2.77) | +/-0.030" (0.76) | +1" (25.4) - 0 | +/-10.0% |

| 8" (203.2) | 0.109" (2.77) | +0.061" (1.55)/-0.031" (0.79) | +1" (25.4) - 0 | +/-10.0% |

Material Grade :

| American Standard | TP304 , TP304L , TP310S , TP316 , TP316L , TP316Ti , TP321 , TP347 , 904L , S31803 Etc |

| European Standard | 1.4301 , 1.4306 , 1.4845 , 1.4401 , 1.4404 , 1.4571 , 1.4541 , 1.4550 , 1.4539 , 1.4462 Etc |

| German Standard | X5CrNi18-10 , X2CrNi19-11 , X12CrNi25-21 , X5CrNi17-12-2 , X5CrNi17-12-3 , X2CrNiMo18-14-3 , X6CrNiTi18-10 , X6CrNiTb18-10 Etc |

1 . OD ( Outer Diameter ) : 15.9mm to 406.4mm

2 . WT ( Wall Thickness ) : 0.89mm to 5mm

3 . Length : According to customer's requirement

4 . Standards : ASTM A312; ASTM A269; ASTM A789; ASTM A790 ect

5 . Process Method : ERW, EFW etc

| Application : | a) For fluid and gas transport |

| b) Structure and machining | |

| c) Heat exchanger pipes etc | |

| Advantages : | a) Superior surface finish |

| b) Better mechanical property | |

| c) More precise dimension | |

| d) Perfect inspection method and inspection equipment | |

| Price Item : | FOB, CFR, CIF or as negotiation |

| Payment : | T/T, LC or as negotiation |

|