| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

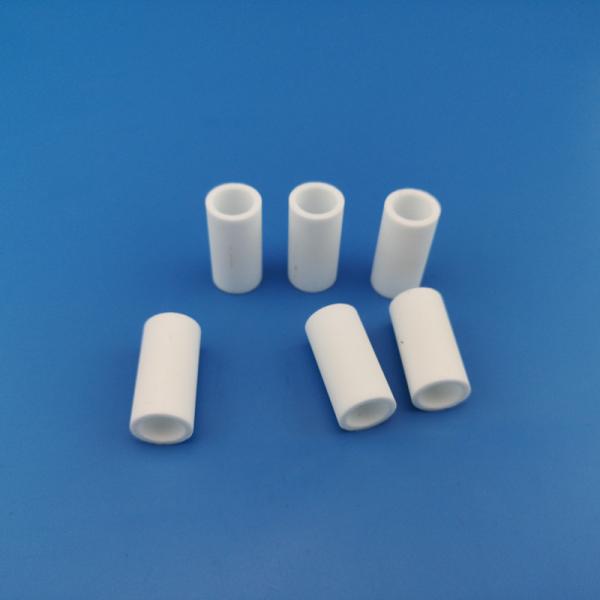

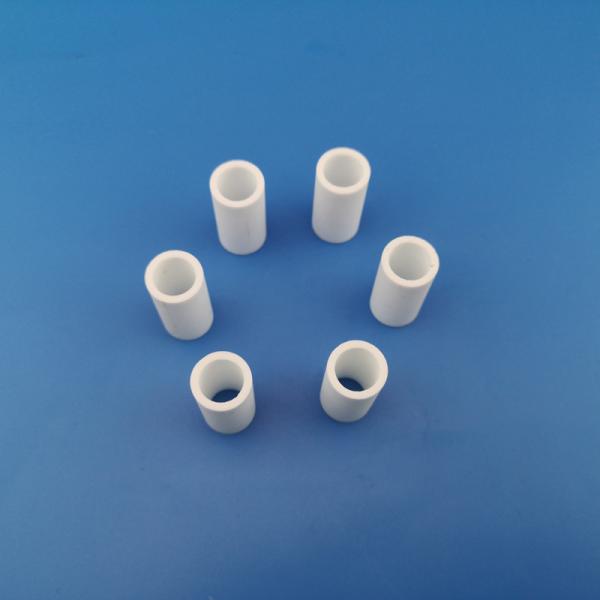

| Categories | Ceramic Tube |

|---|---|

| Brand Name: | Mingrui |

| Model Number: | MR-IN-0674 |

| Certification: | ISO9001 |

| Place of Origin: | China |

| MOQ: | 100 pieces |

| Price: | negotiable |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram, D/P, D/A |

| Supply Ability: | 8000 pieces month |

| Delivery Time: | 23 working days after the order confirmed |

| Packaging Details: | intertional carton box |

| Material: | alumina Ceramic |

| Surface: | Pulishing |

| Dimension: | according your request |

| technology: | machining |

| standard: | International Standard or as your request |

| MOQ: | 5PCS |

| warranty: | 2 years |

| Shipping: | DHL EMS UPS FEDEX TNT |

| Item: | High Temperature Refractory Custom Ceramic Parts Medical Equipment |

| OEM: | yes and |

Alumina Ceramic:

Alumina ceramics are ceramic materials based on alumina (Al2O3) for thick film integrated circuits. Alumina ceramics have good conductivity, mechanical strength and high temperature resistance. It should be noted that ultrasonic cleaning is required. Alumina ceramics is a versatile ceramic. Because of its superior performance, it has been widely used in modern society, satisfying the needs of daily use and special performance.

The applications for alumina advanced ceramics are heavy-duty forming tools, substrates and resistor cores in the electronics industry, tiles for wear protection and ballistics, thread guides in textile engineering, seal and regulator discs for valves, heat-sinks for lighting systems, protection tubes in thermal processes or catalyst carriers for the chemicals industry.

Specification:

1. Refractory, High Temperature Resistance, Maximum Used Temperature: 1800 ºC (3272ºF)...

2. Hardness Strength Up To Mohs 9.0; HRA 80-90, Wear Resistance wear rate 0.68 mm3·m-2·h-1....

3. High Voltage, Good Insulation Performance ,Electrical Resistivity Up To 10∧14 Ohm.Cm...

4. High Polished Surface Up To Rz0.8(Ra0.1) ...

5. Superior Mechanical Strength, Max 10 MPa.m1/2 Fracture toughness,

6. Pressure Resistance, Max 2300MPa compressive strength...

7. Anti-High Corrosion Resistance, Such As Acid Alkali Resistance...

8. Long Service Life...

9. Other excellent property

Data Sheet↓

Alumina Ceramic Properties | 96 Alumina Ceramic | 99 Alumina Ceramic | |

| Item | Unit | Typical Values | |

| Physical Properties | |||

| Color | White | Ivory | |

| Density | g/cm3 | 3.7 | 3.85 |

| Alumina Content | % | 96% | 99% |

| Gas permeability | 0 | 0 | |

| Water Absorption | 0 | 0 | |

| Mechanical Properties | |||

| Rockwell Hardness | HRA | 80 | 82 |

| Vickers Hardness (Hv50) | Gpa(Kg/mm²) | 15.7(1600) | 15.7(1600) |

| Flexural Strength(20°C) | Mpa | 300 | 330 |

| Compressive Strength(20°C) | Mpa | 2000 | 2000 |

| Modulus of Elasticity (20°C) | Gpa | 275 | |

| Poisson's Ratio (20°C) | 0.22-0.23 | ||

| Fracture Toughness(20°C) | MPam1/2 | 3.5 | 4 |

| Thermal Properties | |||

| Thermal Conductivity(20°C-400°C) | W(m.K) | 25 | 27.5 |

| Thermal Expansion Coefficient | 10-6/°C | 6.5-7.5 | 7.6 |

| Thermal Shock Resistance | T°C | 200 | 200 |

| Maximum Use Temperature | °C | 1600 | 1650 |

| Electronic Properties | |||

| Dielectric Strength | KV/mm | >12 | >10 |

| Dielectric Constant | Er | 9-10 | 9.1 |

| Dielectric Loss Angle(1MHz) | 0.0002 | 0.0002-0.0003 | |

| Volume Resistivity(20°C) | Ω.cm | >1014 | >1014 |

Application industry: Machinery, fiber optic, knife, medical, food,

petroleum etc.

Specific application: plunger, ceramic shaft, fiber optic bushing,

stub, grinding, ceramic knife, ceramic slide guide, machined

plunger, mobile phone shell, watch case, haircut razor blade etc.

Delivery:

Custom OEM will be shipped within 15 days after determining the

parameters

The samples will be shipped within 3 days

Quick Delivery Via Fedex,DHL,UPS,TNT Etc.

Support customer to designate shipping company

For more informations (the price,delivery time,moq etc)about the

ceramic plates, please contact us or email:admin@cerampart.com

CEO: Admin deng

Dongguan Mingrui Ceramic Tech. Co. Ltd.

Add: No.21 Chuangxing Rd., 2nd Industrial Zone of Shangsha,

Chang'an town, Dongguan city, Guangdong, China 523867

Email: admin@cerampart.com

FAQ

1. Monthly Capacity: 50,000-60,000 pcs;

2. Material: OEM or as per your suggestion;

3. Lead time: about 7-20 days, pls confirm the quantities required;

4. Incoterm: FOB, CFR, CIF;

5. Delivery Cost: It is determinated by the destination port;

6. Payment Term: PayPal; T/T; L/C.

7. Shipment: by sea, by air, by courier, by post, etc.

|