| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Preform Injection Molding Machine |

|---|---|

| Brand Name: | FillPack |

| Model Number: | FP-3850 |

| Certification: | CE. ISO9001 |

| Place of Origin: | China,JiangSu,Zhangjiagang |

| MOQ: | 1 |

| Price: | USD $54050/set |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 1 set / month |

| Delivery Time: | 35-40 days after deposit receipt |

| Packaging Details: | Wooden Case Package |

| Warranty: | 1 Year |

| Clamp tonnage: | 3850KN |

| Mould Thickness: | 280-680mm |

| Type: | Preform Injection |

| Weight: | 11.5T |

| Machine Type: | Hydraulic |

| Condition: | New |

| Company Info. |

| Zhangjiagang City FILL-PACK Machinery Co., Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

Barrel preform injection machine / equipment / device / system /

plant with high quality SUS316 mould

Parameter:

| MODEL | 3850A | ||

| INJECTION UNIT | A | B | |

| Screw diameter | mm | 63 | 65 |

| Shot weight | g | 1008 | 1072 |

| Screw L/D ratio | L/D | 22.7 | 22 |

| Nozzle Diameter | Srmm | 20 | |

| CLAMPING | |||

| Toggle stroke | mm | 660 | |

| Mould Thickness | mm | 280-680 | |

| Ejector tonnage | KN | 80 | |

| Hole Diameter | mm | 160 | |

| OTHERS | |||

| Heat power | KW | 17.5 | |

| Machine dimension | m | 7.0X2.2X2.0 | |

| Oil tank capacity | L | 400 | |

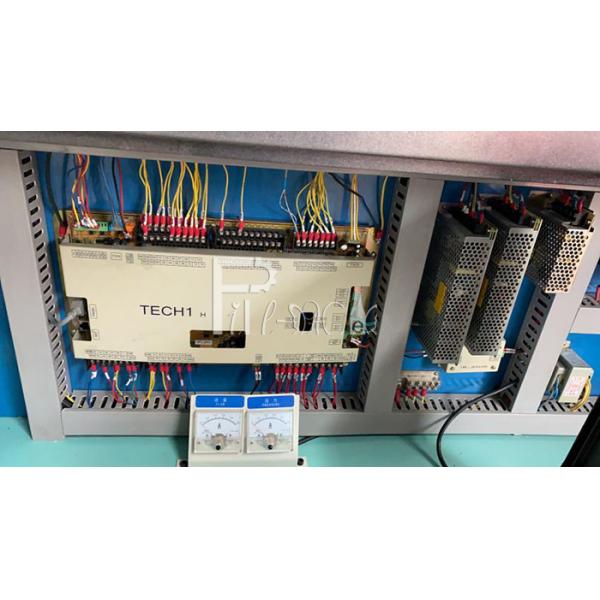

Keyboard input control pannel, electrical components details

PLC control system deatils:

Preform inject mould details for reference:

| Recommended different preform moulds specifications based on standard gram | |||

| Moulds manterial | Cavity(Pcs) | Gram weight(g) | Capacity(pcs/hour) |

Option1:P20 outside, Main accessories S136 Option2: SUS 316 | 1 | 800 | 45 |

| 750 | |||

| 730 | |||

| 700 | |||

| 680 | 50 | ||

| 650 | |||

| 620 | |||

| 600 | |||

| 580 | 55 | ||

| 560 | |||

| 530 | |||

2 | 480 | 120 | |

| 430 | |||

| 400 | |||

| 350 | |||

| 320 | |||

Spare parts list for host inject machine part:

| Item | Free spare parts | Price for additional spare parts/USD |

1, Heating band for barrel | 1pcs | $35 |

| 2, Heating band for nozzle | 1pcs | $26 |

| 3, Sealing rings | 1sets | $25 |

| 4, Solid-state relay | 1pcs | $15 |

| 5, Proximity switch | 2pcs | $12 |

| 6, thermocouple | 1pcs | $12 |

| 7, socket head wrench | 1sets | $16 |

| 8, Mold clip | 8pcs | $180 |

| 9, Level pad | 1pcs | $130 |

| 10, Socket & plug | 2pcs | $17 |

The matching for recommended auxiliaries devices:

| Auto loader | |

| Capacity | 480KG/H |

| Lifting | 5m |

| Static wind pressure | 2400mm/H20 |

| Materials storage tank volume | 7.5L |

| Inner diameter of feeding tube | 38mm |

| Host machine size | 500*400*720mm |

| Materials storage tank size | 450*320*450mm |

| Host machine weight | 66KG |

| Materials storage tank weight | 7KG |

| Water chiller | |

refrigerating output | 99005BTU/H |

| 29KW | |

| 24940kcal/h | |

| 10HP | |

| Compressor power | 8.5KW |

| water pump power | 0.75KW |

| Standard water flow | 95L/MIN |

| Standard water tube diameter | DN40 |

Type of condenser | High efficiency copper tube series aluminum chip + low noise axial flow fan |

| Restrictor | capillary |

| refrigerant | R22 |

| Type of evaporation | Water tank type |

| Water tank volume | 215L |

| dimension | 1300*770*1331mm |

| Weight | 450KG |

| Plastic crusher | |

| Motor power | 20HP(15KW) |

| Diameter | 610*320mm |

| Capacity | 600-800KG/H |

| fixed knife | 2pcs |

| Moving knife | 18pcs |

| dimension | 1200*1120*1630mm |

|