| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Sealant Extruder |

|---|---|

| Brand Name: | JINAN LIJIANG |

| Model Number: | LJTJ2540 |

| Certification: | CE |

| Place of Origin: | China |

| MOQ: | 1 |

| Price: | Negotiable |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 10set/month |

| Delivery Time: | Within 20days |

| Packaging Details: | Container |

| Name: | Automatic Insulating Glass Silicone Extruder Machine |

| Applicantion: | Insulating glass processing |

| Usage: | Silicone Extruder |

| Max glass size: | 2500*4000mm |

| Min glass size: | 300*300mm |

| Working speed: | 5-40m/min |

| Glass thickness: | 12-50mm |

| Air pressure: | >0.6MPa |

| Power: | 380V 12kw |

| Dimension: | 8700*2000*3500mm |

| Squeeze pressure: | 32MPa |

| Fuction: | Sealant Extruder |

Product overview of sealant sealing machine

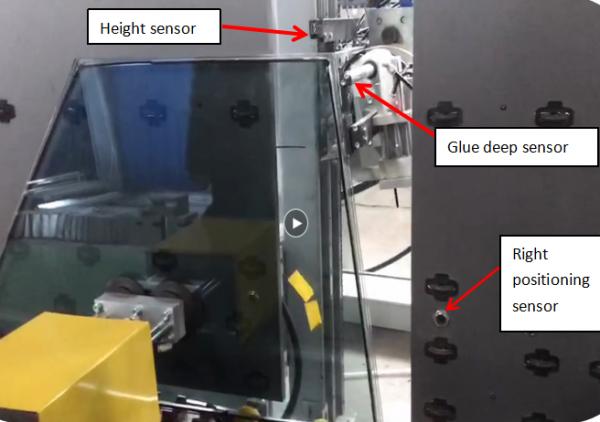

Silicone Extruder Machine can apply the mixed sealant evenly to the outer channel of the insulating glass through the servo mechanism to help the sealing and bonding performance of the insulating glass.It is an important link in the manufacture of hollow glass.

Tech Parameters of Sealant dispensing equipment

| Max.glass size | 2500*4000mm |

| Min.glass size | 300*300mm |

| Glass thickness | 12-50mm |

| Working speed | 5-40m/min |

| Air pressure | 0.6-0.8MPa |

| Squeeze pressure | <350kg/m³ |

| Plane angle | 6°- 9° |

| Max glass weight | 400kg |

| Voltage power | 380V 12kw |

| Overall dimension | 8700mm*2000mm*3500mm |

Main feature of small extruder machine

1.The glass corners are full without air bubbles, smooth surface, no corner trimming required

2.Adopt 8 sets Japan ANCHUAN servo motors

3. Equipped with single A component and single B component. Glue A and B automatic mixing, automatic ratio.

4.Glue system can be selected

One Set of Glue System Equipped with single A component and single B component.

Two Sets of Glue Systems Equipped with two sets of A components and two sets of B components, which can be used for two kinds of different sealants, such as silicone rubber, polysulfide rubber, silicone structural adhesive and so on.

5.Back Glue Device

When the pressure increasing, more Glue B will flow back automatically, saving materials.

6. Automatically measure glass size, glue depth and glue speed with linear adjustment

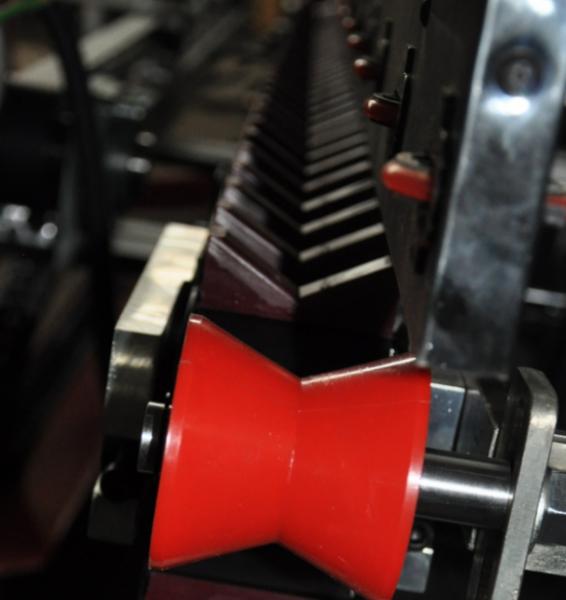

7.Timing belt

The time belt device ensure that glass can be smooth transmission and positioned accurately.

8. Two Suckers Device

Adopting two suckers for preventing to move glass during sealing.

Related products

Automatic spacer bending machine LJZW2020

Automatic spacer bending machine is a special equipment for making aluminum frames of insulating glass, which replaces the traditional fabrication technology. This equipment can make a variety of convex polygonal aluminum frames by one aluminum strip in one time, thus strengthening the strength of the aluminum frame, making the sealing effect of the insulating glass more better.

spacer bending machine details

Company introduction

Jinan Lijiang Automation Equipment Co., Ltd. is an enterprise which integrated glass processing equipment research and development, sales and service into a whole.

Mission:Make glass processing simpler and more intelligent

Vision:Living for 100 years, become refined, specialized and excellent. We will be deeply engaged in the glass machinery industry, and be a high cost-effective specialty in glass machinery industry field. Hope to serve more than 10000 customers around the world by 2030.

|

|