| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Thermocouple Cable |

|---|---|

| Brand Name: | OHMALLOY/OEM |

| Model Number: | SP-N-VS-VA-0.81 |

| Certification: | ISO9001 |

| Place of Origin: | China |

| MOQ: | 50 meters |

| Payment Terms: | L/C, T/T, ,Paypal |

| Supply Ability: | 300000 meters per month |

| Delivery Time: | 3-15working days after payment confirmed |

| Packaging Details: | Coil+plywood case |

| Name: | Vitreous Silica Type N Thermocouple Cable 800℃ |

| Conductor Material: | +NiCrSi -NiSiMg |

| Conductor Size: | 0.81mm |

| Working Temperature: | 0-1000℃ |

| Insulation and Jacket: | Vitreous Silica(long term:800℃,short term:1000℃) |

| Color Code: | IEC(or customized) |

| Guarantee: | 3 Years |

| Company Info. |

| Ohmalloy Material Co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

Vitreous Silica Type N Thermocouple Cable 800℃ High Temperature Furnace Sensor Cable

| Cable Specification | ||||

| Item Name | Thermocouple Type N Cable |  | ||

| Conductor Material | +NiCrSi -NiSiMg | |||

| Conductor Dia | 2*0.81mm(20AWG, 0.5mm2, ±0.01mm) | |||

| Inner Insulation and Thickness | Vitreous Silica (long term: 800℃, short term: 1000℃) | |||

| Inner Insulation Diameter | 1.2mm(±0.2mm) | |||

| Outer Jacket Material | Vitreous Silica (long term: 800℃, short term: 1000℃) | |||

| Finished Diameter | 1.8mmx2.7mm(±0.2mm) | |||

| Weight | 15.6KG/KM | |||

Conductor Chemical Composition

| Material | Chemical composition (%) | ||||

| Cr | Ni | Si | Mg | Al | |

| NP(NiCrSi) | 14.5 | 84 | 1.5 | ||

| NN(NiSiMg) | 94.5 | 4.5 | 1 | ||

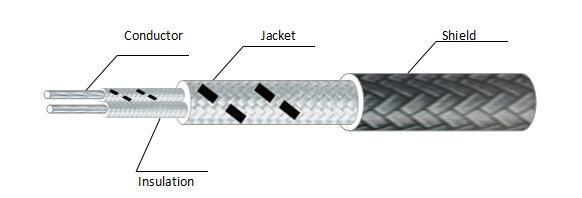

For the extension/compensation cable, the basic structure is conductor and insulation.

To increase its temperature bearing ability and to install easily, jacket is applicable.

In the working environment, there are too much factors will interference the EMF signal, therefore shield layer is practical way to prevent the cable from interference caused by complex environment.

Thermocouple Extension Cable-Know How

The Compensation Wire Name and Code

| Compensation Alloy Wire Name | Positive | Negative | ||

| Name | Code | Name | Code | |

| Copper-Copper Nickel 0.6 | Copper | SPC | Copper Nickel 0.6 | SNC |

| Copper-Copper Nickel 0.6 | Copper | RPC | Copper Nickel 0.6 | RNC |

| Iron-Copper Nickel 22 | Iron | KPCA | Copper Nickel 22 | KNCA |

| Copper-Copper Nickel 40 | Copper | KPCB | Copper Nickel 40 | KNCB |

| Chromel-NiSi3 | Ni90Cr10 | KPX | Ni97Si3 | KNX |

| Iron-Copper Nickel 18 | Iron | NPC | Copper Nickel 18 | NNC |

| NiCr14Si-NiSi4Mg | NiCr14Si | NPX | NiSi4Mg | NNX |

| NiCr10-Copper Nickel 45 | NiCr10 | EPX | Copper Nickel 45 | ENX |

| Iron-Copper Nickel 45 | Iron | JPX | Copper Nickel 45 | JNX |

| Copper-Copper Nickel 45 | Copper | TPX | Copper Nickel 45 | TNX |

The Compensation Wire Nominal Chemical Composition

| Alloy Name | Code | Nominal Chemical Composition(%) | |||||

| Cu | Ni | Cr | Si | Fe | Mg | ||

| Copper | SPC | 100 | - | - | - | - | - |

| RPC | |||||||

| KPC | |||||||

| TPC | |||||||

| CuNi0.6 | SNC | 99.4 | 0.6 | - | - | - | - |

| RNC | |||||||

| NiCr10 | KPX | - | 90 | 10 | - | - | - |

| EPX | |||||||

| NiCr14Si | NPX | - | 84 | 14.5 | 1.5 | - | - |

| NiSi3 | KNX | - | 97 | - | 3 | - | - |

| NiSi4Mg | NNX | - | 94.5 | - | 4.5 | - | 1.0 |

| CuNi40 | KNCB | 60 | 40 | - | - | - | - |

| CuNi22 | KNCA | 78 | 22 | - | - | - | - |

| CuNi18 | NNC | 82 | 18 | - | - | - | - |

| CuNi45 | ENX | 55 | 45 | - | - | - | - |

| JNX | |||||||

| TNX | |||||||

| Iron | NPC | 100 | |||||

| JPX | |||||||

| KPCA | |||||||

|