| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Stainless Steel Tube |

|---|---|

| Brand Name: | Torich |

| Model Number: | ASTM A312 |

| Place of Origin: | zhejiang, China |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Delivery Time: | 30-45days |

| Packaging Details: | In hexagonal bundles or wooden box |

| Product Name: | Large Big Diameter Industrial Stainless Tube Pipe |

| Technique: | Cold Rolled |

| Section Shape: | Round |

| Production Process: | ERW |

| Usage: | Fluid Pipe, Gas Pipe, OIL PIPE |

| Brand: | Torich |

| Certificate: | ISO9001,ISO14001,TS16949 |

| Company Info. |

| TORICH INTERNATIONAL LIMITED |

| Verified Supplier |

| View Contact Details |

| Product List |

TORICH ASTM A312 Large Big Diameter Industrial Stainless Steel Tube and Pipe

Size

| Seam Type | OD | WT |

| Single Seam | 6-914mm | 0.5-60mm |

| Double Seam | 630-1524mm | 2-80mm |

| Circular Seam | over 630mm | 2-100mm |

Material Available

| Material | Grade |

| Austenitic Stainless Steel | 310S, 309S, 316L, 321, 304, 304L |

| Duplex | S32750, S32760, S31803, S32205 |

| Nickel-Based Alloy | N08904, N06600, N08825 |

| Copper Nickel Alloy | C70600, C70620 |

| Ferrite | 430, 409L |

| Other Special Material | 254SMO, 253MA |

| High-Temp Material | 310S, 309S, S30815 |

| Titanium Alloys | TA2, TA10, TC4 |

Density

| Grade | ρ (kg/dm³) | Calculation Formula | |

0Cr18Ni9 (06Cr19Ni10) SUS304 TP304 | 00Cr19Ni10 (022Cr19Ni10) SUS304L TP304L | 7.93 7.9 | W=0.02491 t(D-t) W=0.02482 t(D-t) |

0Cr17Ni12Mo2 SUS316 TP316 | 00Cr17Ni14Mo2 SUS316L TP316L | 8.0 | W=0.02513 t(D-t) |

Production process of JCOE large diameter straight seam welded pipe:

Steel Coil→ Re-test→ Flat Open and Transverse Shear→ Shear (Longitudinal Shear)→ Edge Planning and Milling→

Butt Welding of Plate→ Forming (Bending/Reeling)→ End Squaring&Tack Welding→ Welding Seam Cleaning→

Automatic Welding→ Radiographic Test→ Solution Treatment→ Rounding→ Straightening→ End Facing Treatment→

Hydrostatic Test→ Pickling Passivation→ Rinse and Dry→ Radiographic Test→ Finished Product Testing→ Marking→

Packing→ Finished Product Warehousing→ Shipping

Application:

Electric Power, Oil Refining, Nuclear Power, Drinking Water, Offshore Engineering&Shipbuilding, Natural Gas, Paper Making, Construction

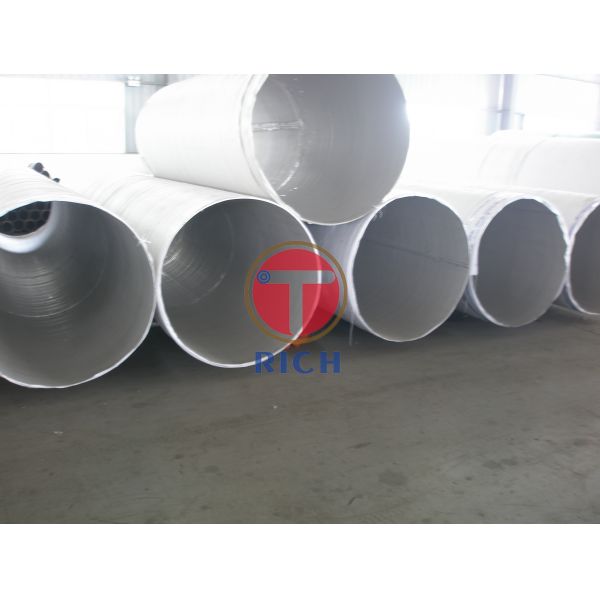

Product Pictures

Company Introduction

QUALITY CONTROL

1. Incoming Raw Material Inspection

2. Raw Material Segregation to avoid steel grade mix-up

3. Heating and Hammering End for Cold Drawing

4. Cold Drawing and Cold Rolling, on line inspection

5. Heat Treatment, +A, +SRA, +LC, +N, Q+T

6. Straightening-Cutting to specified length-Finished Measuring

Inspection

7. Machanical Testing in own labs with Tensile Strength, Yield

Strength, Elongation, Hardness, Impact, Mictrostruture etc

8. Packing and Stocking

100% of our steel tubes are dimensionally checked

100% of our steel tubes are visually checked to assure they have a

perfect surface condition and no surface defects.

100% eddy current test and ultrosonic test to eliminate

longitudinal and transversal defects

|