| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

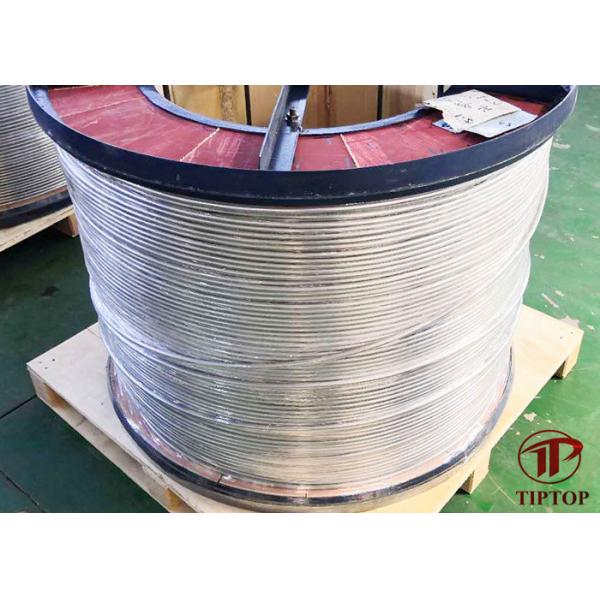

| Categories | SS Stainless Steel Coiled Tubing |

|---|---|

| Brand Name: | TIPTOP |

| Model Number: | 304,316,625,825,2205,2507 |

| Certification: | ISO 9001 |

| Place of Origin: | CHINA |

| MOQ: | Negotiable |

| Price: | Negotiable |

| Payment Terms: | T/T |

| Supply Ability: | 1000 tons per month |

| Delivery Time: | 10 days |

| Packaging Details: | Seaworthy wooden cases or wooden reels |

| Material: | 304,316,625,825,2205,2507 |

| Standard: | ASTM A269 |

| Length: | Maximum 2300 Feets |

| Product: | Maximum Length 2300 Feets Welded SS Stainless Steel Coiled Tubing ASTM A269 |

| OD: | 1/16"~1" |

| Thickness: | 0.02"~0.083" |

| Company Info. |

| Xi'an Tiptop Machinery Co.,Ltd |

| View Contact Details |

| Product List |

Stainless Steel Coil Tube Specification

| Outside Diameter | 1/16” to 3/4" |

| Thickness | 0. 010" to 0.083” |

| Grades | TP - 304,304L,316,316L |

| Seamless Coil Tubing Specifications | ASTM A213 (average wall) and ASTM A269 |

| Welded Coil Tubing Specifications | ASTM A249 and ASTM A269 |

(WELDED 304/L OR 316/L)

| Outside Diameter (OD) | Wall Thickness |

| 1/8” – 3/4” | 0.5mm – 4mm |

Stainless Steel Coil Tube Tolerance

Stainless Steel Coil Tube Specifications – Restricted Tolerance Controls

OD Tolerance: +0.005/-0 in.

Hardness: Maximum 80 HRB (Rockwell)

Wall Thickness: ±10%

Chemistry: Min. 2.5% Molybdenum

Stainless Steel Coil Tube Chemical Composition

The below table shows the chemical composition of the used for Stainless Steel Coil Tubes:

| UNS | C | Mn | P | S | Si | Cr | Ni | Mo | Ti | Nb | N |

| S30400 | 0.08 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-11.0 | ||||

| S30403 | 0.035 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-13.0 | ||||

| S3160 | 0.08 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 11.0-14.0 | 2.0-3.0 | |||

| S31603 | 0.035 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 11.0-14.0 | 2.0-3.0 |

Stainless Steel Coil Tube Mechanical Properties

| Material | Heat | Temperure | Tensile Strength | Yield Strength | Elongation %, Min |

| Treatment | Min. | Ksi (MPa), Min. | Ksi (MPa), Min. | ||

| º F(º C) | |||||

| TP304 | Solution | 1900 (1040) | 75(515) | 30(205) | 35 |

| TP304L | Solution | 1900 (1040) | 70(485) | 25(170) | 35 |

| TP316 | Solution | 1900(1040) | 75(515) | 30(205) | 35 |

| TP316L | Solution | 1900(1040) | 70(485) | 25(170) | 35 |

Application

Industrial use: heat exchanger, boiler, petroleum, chemical, fertilizer, chemical fiber, pharmaceutical, nuclear power.

FAQ

Q1: Can you arrange the shipment?

A: Sure, we have permanent freight forwarder who can gain the best

price from most ship company and offer professional service.

Q2: How long is your delivery time?

A: Generally it is 7-14 days if the goods are in stock. or it is

25-45 days if the goods are not in stock, it is according to

quantity.

Q3. Can you provide customize service?

A: Yes.Pipes can be customized as per the customers' request.

Q4. How to ensure the quality?

A:Mill Test Certificate is supplied with shipment.

If needed, a Third Party Inspection is acceptable.

|