| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Alumina Ceramic Parts |

|---|---|

| Brand Name: | Mingrui |

| Model Number: | XF-593 |

| Certification: | ISO2008, ROHS |

| Place of Origin: | Guangdong, China(mainland) |

| MOQ: | 10PCS |

| Price: | USD3.13-21.06/PC |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram, Paypal |

| Supply Ability: | 5000pcs per week |

| Delivery Time: | 10-30 working days after receiving deposit |

| Packaging Details: | Packed in PP bag or sponge tray, then put in standard export carton packing, or OEM packing. |

| Product name: | Alumina Ceramic Strips |

| Material: | Alumina ceramic |

| Insulation breakdown strength: | 15-18KV/mm, or customized |

| Highest application temperature: | 2200 C, or customized |

| Bending strength: | 300 MPA, or customized |

| Density: | 3.9g/cm3 , or customized |

| Color: | White, yellow, or customized |

| Size: | Customized |

Alumina ceramic (Aluminum Oxide or Al2O3) is an excellent electrical insulator and one of the most widely used advanced ceramic materials. Additionally, it is extremely resistant to wear and corrosion. Alumina components are used in a wide range of applications such as electronics, pump components and automotive sensors.

Featurers

1. material: Alumina ceramic

2. method of moulding: thermal casting/drying press/extrusion

3. colour: white

4. sintering temperature: 1580℃

5. surface finish:Ra0.4 &SIM RA 0.8&mum etc, upon your requirement.

6. package: packing with carton and ship with wooden box.

7. we can produce them by your moulds or the drawings you require.

Properties sheet of alumina ceramic :

| Properties | Units | 95 Alumina | 99 Alumina |

| Density | g / cm³ | 3.65 | 3.92 |

| Water absorption | % | 0 | 0 |

| Coefficient of thermal expansion | 10-6/K | 7.9 | 8.5 |

| Modulus of Elasticity Young's Mod | GPa | 280 | 340 |

| Poisson's ratio | / | 0.21 | 0.22 |

| HV Hardness HV | MPa | 1400 | 1650 |

| Flexural Strength @ room temperature | MPa | 280 | 310 |

| Flexural Strength @700°C | MPa | 220 | 230 |

| Compressive Strength @ room temperature | MPa | 2000 | 2200 |

| Fracture Toughness | MPa *m 1/2 | 3.8 | 4.2 |

| Heat conductivity @ room temperature | W/ m*k | 18-25 | 26-30 |

| Electrical Resistivity @ room temperature | Ω*mm2 /m | >1015 | >1016 |

| Max use temperature | °C | 1500 | 1750 |

| Resistance to acid alkaline | / | high | high |

| Dielectric Constant | / | 9.5 | 9.8 |

| Dielectric Strength | KV/mm | 16 | 22 |

| Thermol Shock Resistance | △ T ( °C ) | 220 | 180-200 |

| Tensile Strength @ 25 °C | MPa | 200 | 248 |

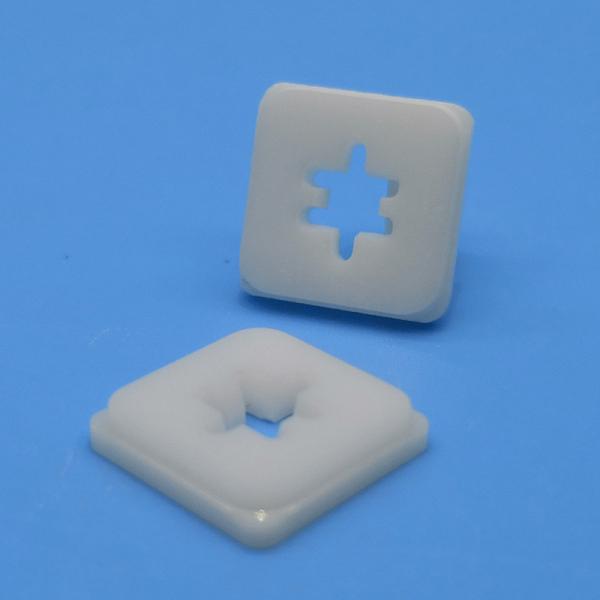

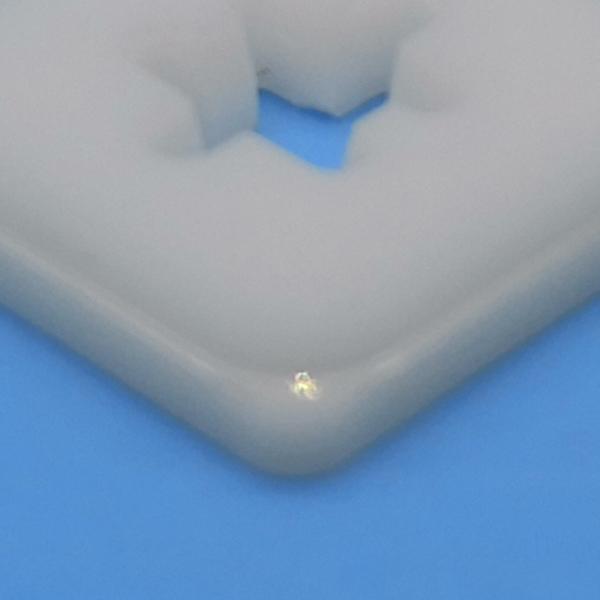

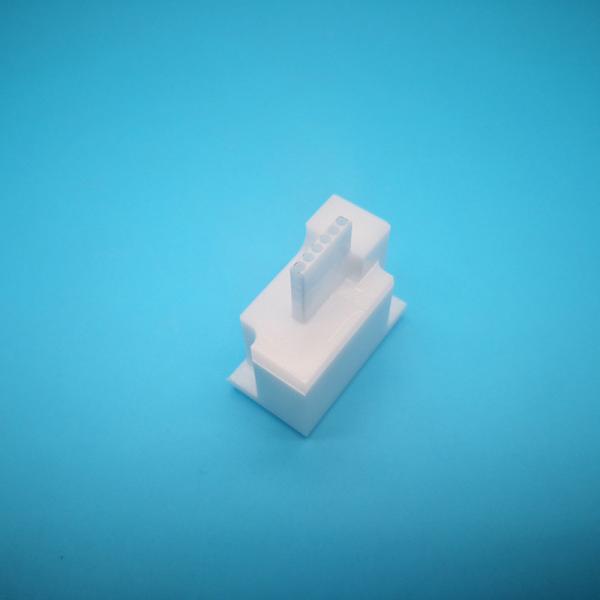

Product Photos Show

Packaging and Shipping

Packed in PP bag or sponge tray, then put in standard export carton

packing, or OEM packing.

Shipped by Air ( DHL, TNT, UPS, Fedex, EMS ), or Sea

transportation.

Company information

Who Are We?

Mingrui is a professional factory with years OEM experience in

manufacturing industrial ceramic parts.

What Do We Do?

We produce (OEM ) strengthened structure zirconia and alumina

ceramic rod,tube, shaft, plate, sleeve, valve, plunger, bearing,

nozzle and ceramic arm, they are applicable to instruments, medical

instruments, clocks and electronic products, mills, energy and

power, machine and metals, autocar and military, spaceflight and

some other high-end fields.

All of our products with certificates, such as , CE, TUV, and so

on.

Factory Show

Production Process Show

Certificates Show

|