| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Alumina Ceramic Parts |

|---|---|

| Brand Name: | Mingrui |

| Model Number: | XF-590 |

| Certification: | ISO2008, ROHS |

| Place of Origin: | Guangdong, China(mainland) |

| MOQ: | 10PCS |

| Price: | USD3.13-21.06/PC |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram, Paypal |

| Supply Ability: | 5000pcs per week |

| Delivery Time: | 10-30 working days after receiving deposit |

| Packaging Details: | Packed in PP bag or sponge tray, then put in standard export carton packing, or OEM packing. |

| Material: | Alumina ceramic |

| Insulation breakdown strength: | 15-18KV/mm, or customized |

| Highest application temperature: | 2200 C, or customized |

| Bending strength: | 300 MPA, or customized |

| Compressive Strength: | 3400 MPA, or customized |

| Density: | 3.9g/cm3 , or customized |

| Size: | Customized |

Aluminas (aluminum oxide, Al2O3) are the most commonly used technical ceramics due to their generally useful properties and good price/performance ratio. Alumina ceramics are commonly subdivided according to their alumina content ranging from 80% to more than 99%. Higher purity alumina demonstrates enhanced wear and corrosion resistance — creating a continuous scale of various alumina grades, compositions, and performance.

Aluminas are used in both general use and specialized applications. A grade is selected to fit the application environment. Alumina compositions and microstructures can be formulated to meet the specific performance requirements of more demanding applications.

General use

Wear resistance

Electrical insulator

Dielectric strength

Low dielectric loss

Product Description

Performance For Industrial Ceramic | |||

Item | Character | Unit | Zirconia |

Physical Characteristics | Heat resistance | 0C | 2000 |

Bulk density | g/cm3 | 6.00 | |

Water absorption | % | 0 | |

| Flexural strength | Mpa | 950 |

Hardness vickers | Gpa | 89 | |

Elastic modulus | Gpa | 200 | |

Poisson’s ratio | 0.31 | ||

Thermal Characteristics | Linear expansion coefficient | (20-5000C)10-6/0C | 10 |

Thermal conductivity | w/(m.k) | 2.5 | |

Specific Heat | *10-3J/(kg*K) | 0.5 | |

Electrical Characteristics | Dielectric constant (1MHZ) | - | N.A. |

Dielectric loss angle | *10-4 | N.A. | |

Dielectric strength | *106V/m | N.A. | |

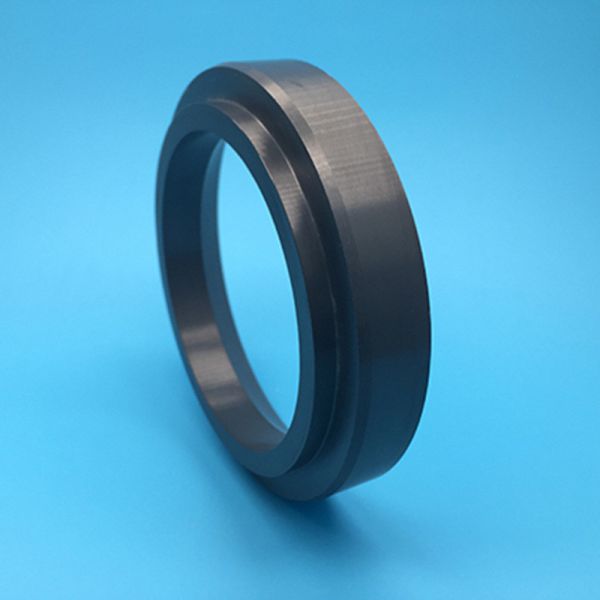

Product Photos Show

Packaging and Shipping

Packed in PP bag or sponge tray, then put in standard export carton packing, or OEM packing.

Shipped by Air ( DHL, TNT, UPS, Fedex, EMS ), or Sea transportation.

Company information

Who Are We?

Mingrui is a professional factory with years OEM experience in

manufacturing industrial ceramic parts.

What Do We Do?

We produce (OEM ) strengthened structure zirconia and alumina

ceramic rod,tube, shaft, plate, sleeve, valve, plunger, bearing,

nozzle and ceramic arm, they are applicable to instruments, medical

instruments, clocks and electronic products, mills, energy and

power, machine and metals, autocar and military, spaceflight and

some other high-end fields.

All of our products with certificates, such as , CE, TUV, and so on.

Factory Show

Production Process Show

Certificates Show

Our service

FAQ

Our Factory Welcomes Your Visiting!

|