| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | PET Bottle Recycling Machine |

|---|---|

| Brand Name: | XINTING |

| Model Number: | XT300-3000 |

| Certification: | CE ISO |

| Place of Origin: | CHINA |

| MOQ: | 1 set |

| Price: | NEGOTIATE |

| Payment Terms: | L/C, , T/T |

| Supply Ability: | 1 set per month |

| Delivery Time: | 30 days |

| Packaging Details: | film package or wood package |

| Plastic Type:: | PP/PE/PVC/PET/ABS/EVA Brand Name: |

| Automatic Grade:: | Automatic |

| Dimension(L*W*H):: | 115x5x4.5m |

| Capacity:: | 150-850kg/h |

| Blades Material:: | D2 Alloy Steel |

| Color:: | Clients' Demand |

| The size of end powder:: | 20-120mesh |

| Warranty:: | 1 Year, 12 Months |

| Company Info. |

| Xinting Machinery Co., Ltd. |

| View Contact Details |

| Product List |

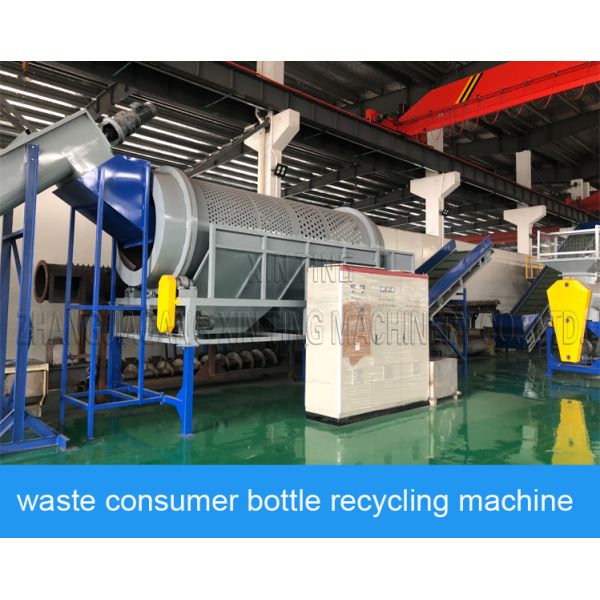

PET Bottle Recycling Machine:

We can manufacturing the production line according to the customer

requirement and final flakes quality requirements;

This production line is high automatic operating and save labor

cost and low after maintenance. Our machinery is widely used in

domestic and abroad in many countries;

Features:

1. We have the Bale opening and feeding system which and equally

feeding the material save labor;

2. You can use the manually sorting system to selecting out

different color bottles and non-PET material;

3- Metal detector is optional for you which used to take out any

kind of metal from the PET bottles;

4- Specially designed PET bottle Crusher Machine can easily get

high output and with water doing wet griding can extension the blades use life, reduce the dust generation;

5- High speed Dewatering machine and the drying system can

guarantee the final PET flakes moisture <1%.

6- The Fin dust separator machine will remove the final labels from

the flakes to guarantee the PVC content..

| Raw Material | PET Bottles |

| Capacity Model | 500kg/hr, 1000kg/hr, 1500kg/hr, 2000kg/hr, 3000kg/hr |

| Machine List Components: | |

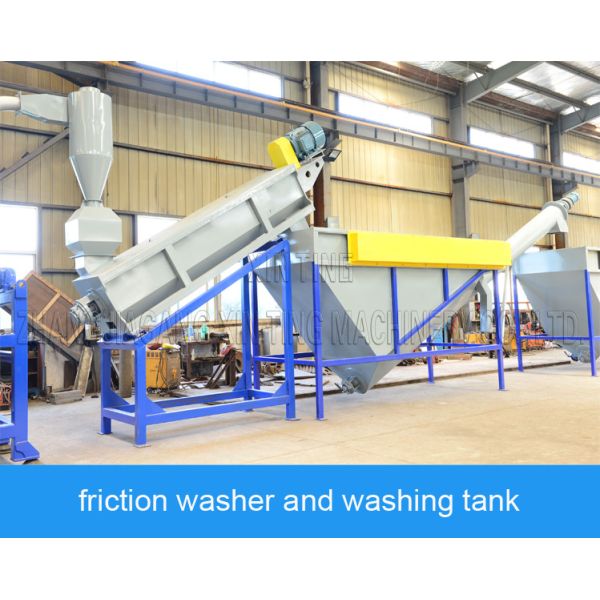

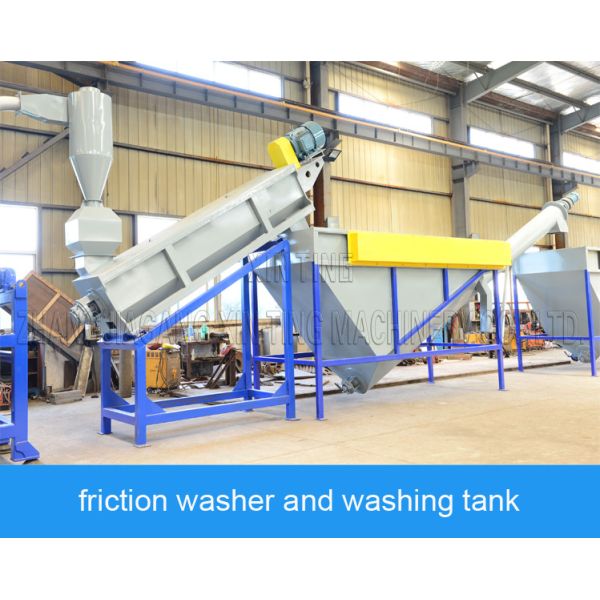

| PVC Label Remover machine---Sorting system---PET Crusher machine---Flakes Floating washing tank---Hot Washing system,---Frication washing system---dewatering machinery and fin dust label separator machine---hot air drying system and the Packing system | |

Ø Machine model: ( PET Bottle Recycling Machine )

· XT 300-3000

Ø Machine Features: ( PET Bottle Recycling Machine )

· Plastic Bottle Recycling Machine

Ø Function description: ( PET Bottle Recycling Machine )

· Plastic Bottle Recycling Machine

Ø Quality Control: ( PET Bottle Recycling Machine )

· We have technical, engineer team design the sample machinery before enter into market

· Production QC team ensure the machine manufacturing quality

· We will running every machine after finished before shipment

· Optional choose by client running the machinery by material

Ø Service System: ( PET Bottle Recycling Machine )

· Pre-sale: we given client the details technician offer, sign the sales contract etc.

· In-sales: we supply the details layout, installation instruction, technician support for the clients;

· After sales: we arrange engineer to install the machinery and training the workers for client;

· We have 24hours team to solve the after sales problem;

· We have free spare parts with the machine;

· We supply long term spare parts for every customer

· We always up date the new technology to every customer

WHAT WE CAN OFFER IS THE FILM WASHING RECYCLING LINE

Ⅰ. PE PP Rigid plastic crushing washing recycling machine line features:

PE PP Rigid plastic crushing washing recycling machine line is widely used to treat waste rigid plastic. It is a crushing, washing and drying line. After finished, these clean flakes could be produced as fibre , straps and so on.

Ⅱ. PE PP Rigid plastic crushing washing recycling machine line working flow:

belt conveyor → crusher → high speed friction washer → floating washer → screw loader → floating washer → screw loader → dewatering machine

|