| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Horizontal Glass Washing Machine |

|---|---|

| Brand Name: | Lijiang |

| Model Number: | LJWBQJ2500 |

| Certification: | CE |

| Place of Origin: | China |

| MOQ: | 1 |

| Price: | Negotiable, |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 20set/month |

| Delivery Time: | 30days |

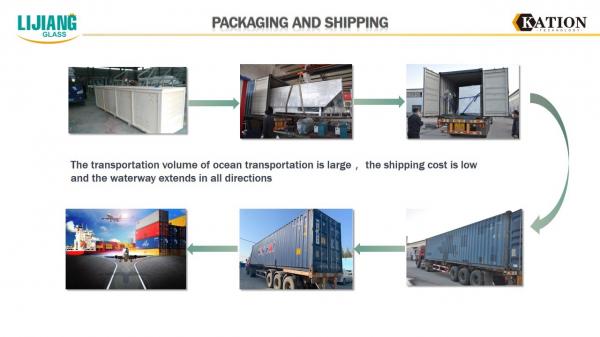

| Packaging Details: | wooden case or container |

| Name: | Horizontal Insulating glass making washing and drying machine |

| Advantage: | easy operate |

| Material: | stainless steel touching water part |

Horizontal Insulating glass making washing and drying machine

Horizontal Insulating glass making washing and drying machineused for cleaning and drying the upper and lower surfaces of ordinary plate glass and high quality low-e glass,it is composed of incoming segment, cleaning air-drying segment and out goingsegment.

►►►Stainless Steel parts showing

►►►The drying part is composed of 2 sets of high-pressure professional air knives.

►►►Glass washer installition in factory

1.Main drive, brush speed regulation method: frequency control

2. Minimum glass specification: 400mm×400mm (limited to single row on left and right sides)

3. Glass thickness: 3mm-25mm (digital display)

4. Speed range: glass thickness within 3-25mm Vmax=1-12m/min

5. Maximum glass width: 2500mm (effective maximum: 2650mm)

6. Table height :900±25mm

| Maximum glass width | 2500mm (effective maximum: 2650mm) |

| Minimum glass specification | 400mm×400mm (limited to single row on left and right sides) |

| Glass thickness | 3mm-25mm (digital display) |

| Speed range | glass thickness within 3-25mm Vmax=1-12m/min |

| Main drive, brush speed regulation method | frequency control |

| Table height | 900±25mm |

| Total power | 42KW(water-bearing wind heating: 15KW) |

| Water source | self-circulation, tap water (according to civil water standards) and deionized water water supplement (deionized water equipment shall be provided by the buyer) |

| Power source | 380V 50Hz |

| Dimensions (length × width × height) | approximately 6260*4800*3100mm |

| Weight | 3940kg |

| Main drive motor | Zhejiang province |

| Brush motor | Zhejiang province |

| High pressure air blower | Guangdong province |

| The water pump | Shanqing |

| brush | Anhui province |

| Rubber roller | Guangdong province |

| Frequency converter | VEICHI/Rexroth |

| Electric parts | Schneider |

Horizontal Insulating glass making washing and drying machine adopts horizontal structure, which is used for cleaning and drying plate type glass;

-The main part consists of inlet, washing, drying, and out of film

-Conveyor adopts chain transmission

-The machine has 1 water tank. primary washing

-There are 4 groups of brushes and 3 groups of absorbent cotton

within the machine

-Reliable, good cleaning effect, easy to adjust;

-Conveying glass Frequency Control, easy to control, is more conducive to connect the bilateral edging production lines, glaze line, insulating glass production line, safety glass production lines

- the transmission adopts gear transmission, variable frequency speed regulation, digital display, easy to operate, it is conducive to connecting the production line

- by three to two on the hard brush brush cleaning, in front of the available cylinder lifting, cleaning all kinds of Low-e glass on soft brush with third.

- the cleaning department and the wind cadres overall lifting, the highest lift is 400mm, easy to clean the internal rubber roller and maintenance

- wind cadres use professional design of two pairs of wind knife, wind knife wind dry better effect!

-special cleaning requirements or attached features can be customized

We could supply one section cleaning, two-section cleaning or multi-sections cleaning.

Related product

Automatic Aluminum Spacer Bending Machine LJZW2020

Main feature

• Adopt Siemens PLC control system, touch screen interface

• Four spacer size storage units

• Siemens servo control system

• Automatically cut and feed aluminum spacers

• Auxiliary function of adjustment for bending large aluminum frame

• Aluminum spacers are available in different sizes and sizes

• Separated guard board outside of bender

• Automatically avoid the connection while bending and cutting

• Pause and Reset device for handling equipment failures

• Bend shaped spacer frames continuously

• USB input function, read the excel format file directly etc (Optional)

• Spacer printing code function (Optional)

• Printing label sticker function (Optional)

• Automatic drill gas filling hole (Optional)

• Connect to ERP system (Optional)

• Can bend aluminum spacer and stainless steel ( Optional)

Technical data

| Max. bending size | 2000mm*2000mm (2500*2500mm) |

| Min. bending size | 250mm*200mm |

| Aluminum spacer width | 5.5-27mm |

| Dimensional error | ±0.5mm |

| Angle error | ±1º |

| Processing speed | ≤26s |

| Air supply | ≥0.65MPa |

| Total power | AC220/380V 50Hz 2.5KW |

| Dimension | 10500mm*2200mm*2600mm |

|