| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Hydraulic Seals |

|---|---|

| Brand Name: | SUNCAR |

| Model Number: | BRT2 BACK UP RING |

| CertifiC-A-Tion: | ISO9001 |

| Place of Origin: | CN |

| MOQ: | 100 pcs |

| Price: | Negotiable |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, |

| Supply Ability: | 550 Pcs Per Week. |

| Delivery Time: | 3-7 Days After Payment Received(Public Holiday Excluded) |

| Packaging Details: | PP Bag Inside,Carton Box Outside. |

| Material: | PTFE |

| Hardness: | 80 shore A |

| Color: | Black |

| Feature: | Seal performance;Wear resistance and low friction characteristics |

| Media: | Hydraulic oil,water,emulsions |

| Style: | Hydraulic seal,Back up ring |

| Function: | Improve the service life of seals |

| Size: | Standard size;can be customize. |

| Suitable for machine: | Hitachi ,C-A-Terpillar, Sumitomo,Kato, Doosan , Komastu,SUNCARSUNCARVOLVO,H |

| Key words: | hydraulic seal, excavator seal , back up ring , gasket seal, BRT |

| Density: | 1.15 g/cm³(PU) |

| Company Info. |

| GUANGZHOU SUNCAR SEALS CO.,LTD. |

| Verified Supplier |

| View Contact Details |

| Product List |

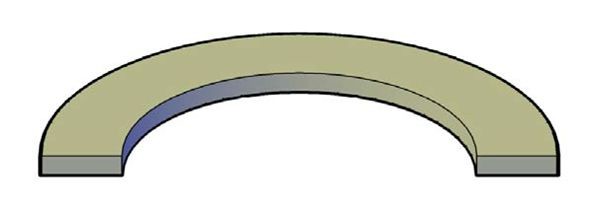

Excavator Hydraulic Seal BRT2 Back-Up Ring

The back-up ring is used to increase the service life of the seal.

For the selection of the retaining ring material, it is required to

have the characteristics of being easy to compress and deform when

pressurized and difficult to be extruded. In addition, during

compression deformation, it moves due to contact with the opposed

sliding surface, so wear resistance and low friction

characteristics are also important

BRT2 Back Up Ring Size:

| Size | Material |

| 10*18*2 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 12*20*2 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 12.5*20*2 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 14*22*2 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 16*24*2 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 17*25*2 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 18*26*2 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 20*28*2 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 20*30*2 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 22*30*2 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 22.4*30*2 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 23.5*31.5*2 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 24*32*2 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 25*33*2 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 25*35*2 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 26*34*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 27*35*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 27.5*35.5*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 28*35.5*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 28*36*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 30*38*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 30*40*2 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 30*40*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 31.5*41.5*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 32*42*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 33*43*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 34*44*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 35*45*2 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 35*45*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 35.5*45*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 35.5*45.5*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 36*46*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 38*48*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 40*50*2 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 40*50*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 45*55*2 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 45*55*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 45*56*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 46*56*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 50*60*2 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 50*60*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 53*63*2 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 53*63*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 55*65*2.5 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 55*65*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 56*66*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 58*68*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 60*70*2.5 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 60*70*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 60*71*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 61*71*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 62*75*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 63*73*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 65*75*2.5 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 65*75*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 65*80*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 67*77*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 67*80*2.5 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 70*80*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 70*85*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 71*80*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 72*85*2.5 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 75*85*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 75*90*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 77*90*2.5 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 80*90*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 80*95*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 85*95*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 85*100*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 85*105*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 86*100*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 89*104*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 90*100*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 90*105*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 90*110*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 95*110*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 95*115*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 96*111*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 98*112*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 100*115*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 100*120*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 105*120*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 105*125*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 106*120*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 110*125*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 110*130*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 112*125*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 115*130*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 115*135*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 118*132*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 118*133*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 120*135*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 120*140*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 125*140*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 130*145*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 130*150*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 132*145*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 135*150*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 136*150*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 140*155*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 145*160*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 150*165*3 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 155*170*4 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 160*175*4 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 165*180*4 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 170*185*4 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 170*190*4 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 175*190*4 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 180*200*4 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 190*210*4 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 190*215*4 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 195*215*4 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 200*220*4 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 200*225*4 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 204*224*4 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 205*225*4 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 210*230*4 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 210*235*4 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 220*240*4 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 220*245*4 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 224*244*4 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 230*250*4 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 240*260*4 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 240*265*4 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 250*270*4 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 255*280*4 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 260*280*4 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 265*290*4 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 275*300*4 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 280*300*4 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 295*315*4 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 300*320*4 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 335*355*4 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 355*375*4 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 380*400*4 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 400*420*4 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 450*470*4 | POLYAMIDE(PA) |

| PTFE 19YF | |

| 500*525*4 | POLYAMIDE(PA) |

| PTFE 19YF |

PU Material Performance Characteristics:

(1) Specific gravity: lighter.

(2) Mechanical properties: good impact resistance, but high water absorption.

(3) Wear resistance: self-lubriC-A-Ting, low abrasion, mostly used in the manufacture of shaft sleeves, gears, scroll bars and other products.

(4) Electrical performance: Due to the influence of moisture and crystallinity, it can only be used for components with comprehensive performance in electronic and electrical.

(5) Flammability: self-extinguishing.

(6) Chemical resistance: In addition to strong acids, strong alkalis, zinc chloride and other chemicals, it is resistant to various chemicals.

(7) Heat resistance: high heat resistance, for example, the softening point of PA66 is 260°C, PA6 is 224°C, and PAl2 is 117°C.

(8) Breathability; low permeability for O and CO, suitable for food packaging film. Due to its high air permeability, it can also be solved by a multilayer composite process with aluminum foil.

(9) After the glass fiber is reinforced, the water absorption and dimensional stability can be greatly improved.

PA Performance Characteristics:

1. High strength: working pressure 0.6~4 OMpa;

2. Maximum working pressure is much higher than existing plastic

pipes;

3. Lightweight: the weight is only 1/7 of the steel pipe, and the

weight in the water is only 1/48 of the steel pipe;.

4. Wear resistance: under the same working conditions, the wear

resistance is 3~4 times that of steel;

5. Temperature resistance: working temperature is-40C~150C, not

cold and brittle at low temperature;

6. Corrosion resistance: resistant to strong alkali, weak acid and

most salt media;

7. Large diameter: the product diameter is 160~1000mm, the maximum

diameter is larger than the existing plastic pipe diameter;

8. Low friction: Under the same working conditions, the pipeline

pressure loss is only 2/3~4/5 of the steel pipe;

9. Impact resistance: impact toughness is equivalent to steel pipe;

10. Anti-aging: The service life in the field can reach more than

50 years;

11. Easy connection.

Back Up Ring OEM Number:

GN5418V0

GN5723V0

GN5724V0

GN5719V0

GN5720V0

GN5725V0

GN4778V0

GN4780V0

GN4781V0

GN5726V0

GN4784V0

GN4786V0

GN5727V0

GNGN5019V1

GN4787V0

GN5728V0

GN5707V0

GN5708V0

GN4791V0

GN5715V0

GN5729V0

GN4662V0

GN4794V0

GN4796V0

GN5730V0

GN5731V0

GN5732V0

GN5765V0

GN4799V0

GN4801V0

GN5716V0

GN5733V0

GN5365V0

GN4672V0

GN4050V0

GN5480V0

GN4804V0

GN4805V0

GN5709V0

GN4976V0

GN4335V0

GN5511V0

GN4693V0

GN5766V0

GN4810V0

GN4766V0

GN5641V0

GN5525V0

GN4676V0

GN4812V0

GN4629V0

GN5712V0

GN4814V0

GN5767V0

GN4816V0

GN4549V0

GN4697V0

GN5768V0

GN4651V0

GN4876V0

GN4818V0

GN5769V0

GN4692V0

GN4971V0

GN5770V0

GN4820V0

GN5023V0

GN4757V0

GN4687V0

GN4821V0

GN4982V1

GN5734V0

GN5735V0

GN4698V0

GN4109V0

GN4822V0

GN4823V0

GN5736V0

GN4824V0

GN4512V0

GN4119V0

GN5198V0

GN4825V0

GN4826V0

GN4480V0

GN4280V1

GN4827V0

GN4593V0

191-5647

1915647

GN4574V0

GN5414V0

GN5718V0

GN5036V0

GN4132V0

GN4481V0

GN4628V1

GN4142V0

GN5737V0

GN5025V0

GN4830V0

GN4526V0

GN4551V0

155-9103

1559103

GN4833V0

GN4834V0

GN4835V0

GN4836V0

GN5464V0

GN4529V0

GN4839V0

GN4470V0

GN4841V0

GN4577V0

GN5746V0

GN4385V0

GN4560V0

GN4842V0

GN5710O0

GN4627V0

GN5758V0

GN4444V0

GN5754V0

GN5132V0

GN4635V0

GN4845V0

GN4428V1

GN4459V0

GN4846V0

GN5563V0

GN4848V0

GN4852V0

GN5459V0

GN5738V0

GN5581V0

|