| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

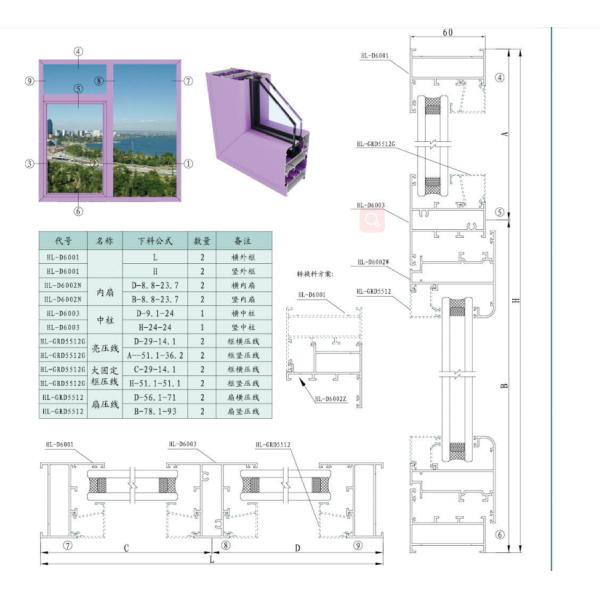

| Categories | Window Aluminum Profile |

|---|---|

| Brand Name: | Huilv |

| Model Number: | HL-D60 |

| Certification: | ISO9001:2008/ ISO14001:2004/ OHSAS 18001:1999/PPG/TUV/CE |

| Place of Origin: | China |

| MOQ: | 300Kg |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 50 000 Tons/Year |

| Delivery Time: | Within 5-15 working days |

| Packaging Details: | inner protection film stick on each profile, outter packed by the carton. |

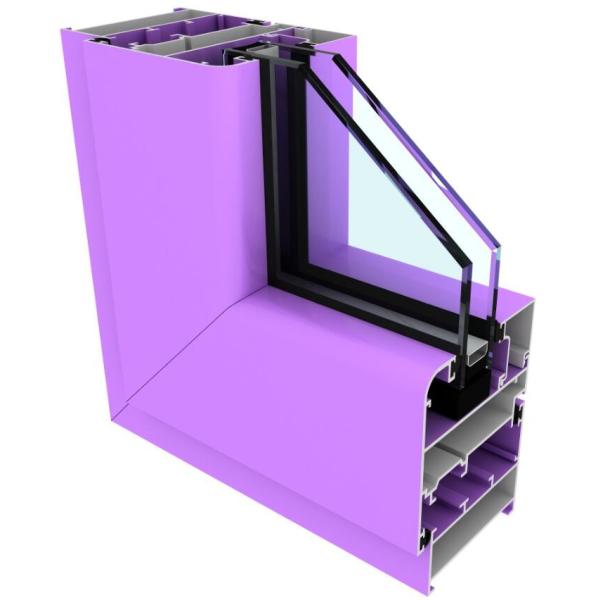

| Material: | 6063 aluminum alloy |

| Colour: | customized |

| Glass: | 6mm+12A+6mm |

| Frame thickness: | 1.4mm , customized |

| Glass material: | tempered glass, customized |

| Guarantee: | 10 years |

| Aging: | T4 T5 T6 |

| Opening way: | casement |

| Energy-efficient: | no, general profiles |

| glass layers: | double |

Inward Outward Casement Window General Aluminium Frame

| Description | Casement Window Frame |

| Window profiles Thickness | ( 0.6, 0.7, 0.8, 1.2, 1.4, 2.0 ) mm OR customized |

| Material | Aluminum Alloy 6061 6063 6005 6060 T5 T6 |

| Colors | Silver White ,Grey, Bronze , Champagne, Black, (RAL series)etc. Or According to your sample. |

| Glass specification | 8mm+12A+8mm ,or customized |

| Surface treatment | mill finish, powder coating, anodize, polish, electrophoresis, wood grain |

| Decoration Film thickness | Anodizing 10um, electrophoresis 20um, powder coating 40um |

Mold fee | Refund after quantity reach 5 tons appoximately for each kind |

| Package | 1. foam paper for each profile; |

| Advantages/Features | We have our own design and manufacturing departments workshops. |

| Payment | 30% down payment by T/T and rest after the copy of BL. Or L/C. Or we can discuss. |

| Shipping term | EXW, FOB, CIF or discussed. |

| Shipping port | Shanghai/Nanjing/Wuhu Port |

Aluminium Profile Materials:

Aluminium Alloy: 6063, 6061, 6005, 6060 Thermal Treatment: T5-T6

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other Impurity | Al | |

| Unit | Total | ||||||||||

| 6063 | (0.2-0.6)% | <0.35% | <0.1 | <0.1 | 0.45-0.9 | <0.1 | <0.1 | <0.1 | <0.05 | <0.15 | all the rest |

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.4 | <0.15 | 0.8-1.2 | 0.04-0.35 | <0.25 | <0.15 | <0.05 | <0.15 | all the rest |

| 6005 | 0.6-0.9 | <0.35 | <0.1 | <0.1 | 0.4-0.9 | 0.1 | <0.1 | <0.1 | <0.05 | <0.15 | all the rest |

| 6060 | 0.3-0.6 | 0.35-0.6 | 0.1-0.3 | <0.1 | <0.1 | <0.15 | <0.05 | <0.1 | <0.05 | <0.15 | all the rest |

T5: After extruding aluminum profiles from the extruder, the temperature is rapidly reduced by air cooling to meet the required hardness (8 to 12 degrees Webster).

T6: After extruding aluminum profiles from the extruder, then cooled by water to achieve higher hardness (over 13.5 Webster’s).

|