| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Railway Axle |

|---|---|

| Brand Name: | Railteco |

| Certification: | ISO9001,ISO14001, OHSAS18001, AAR, IRIS, TSI |

| Place of Origin: | China |

| MOQ: | One pcs |

| Payment Terms: | L/C, T/T |

| Supply Ability: | Annual capacity of 40,000 pcs |

| Delivery Time: | 60 days after advance payment and drawing confirmation |

| Packaging Details: | Railteco's Standard Packing |

| Price: | Negotiable |

| Name: | Railway Locomotive Axle |

| Material: | LZ50, AAR Grade F, EA1N, IRS 16/95, and etc. |

| Standard: | TB, AAR, UIC, EN, BS, IRS, JIS, KSR, GOST and etc. |

| Test: | Chemical, Metallographic, Mechnical, UT, MT and etc. |

| Process: | Cutting, Heating, Forging, Straightening, Rough and Semi-Finish Machining |

| Company Info. |

| Jiangsu Railteco Equipment Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

Railway Axle Locomotive Axle Train Axle Metro Axle Wagon Axle

AAR Axle GOST Axle TSI Axle

Description of Railway Locomotive Axle:

| Product Name | Railway Locomotive Axle |

| Wide Material | Axles wide range of raw material steel support LZ50, JZ45,AAR Grade F, EA1N, EA1T, EA4T, IRS 16/95, SFA60A, and etc. |

| Wide Standards | Axles confirm to every recognized international quality standard: TB/T 2945, AAR M-101, UIC 811-1, EN 13261, BS 5892 PART 1, IRS 16/95, JIS E 4502, KSR 9220, GOST 31334 and other customer's requirement. |

| Size | According to customers' drawings. We can produce all kinds of truck gauges Railway Locomotive Axle. The axle length range from 1200 to 2800mm |

| Test | We can do all the tests according to different standards. Such as: Chemical analysis, Metallographic, Mechnical analysis, Ultrasonic testing, Magnetic testing, Impact testing, Hardness testing, Surface quality and dimensions. |

| Certifications | ISO9001,ISO14001, OHSAS18001, AAR, IRIS, TSI |

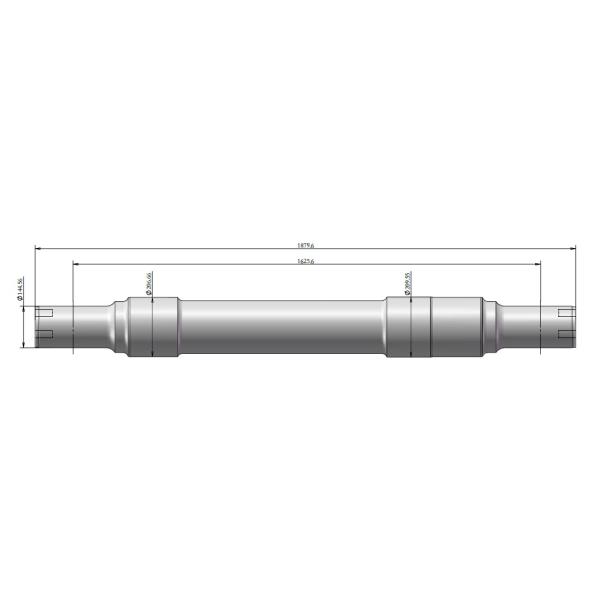

Locomotive Axle

| Parameter | |

| Axle length | 1879.6mm |

| Journal Diameter | 144.56mm |

| Wheel seat Diameter | 206.66mm |

| Gear seat Diameter | 209.55mm |

| Bearing center distance | 1625.6mm |

Manufacturing Process:

Billet Steel Review→ Cutting→ Heating→ Forging→ Straightening→ Heat Treatment→ Sampling Test→ Rough Machining→ Semi-Finish Machining→Ultrasonic Inspection→ Finish Machining→ Grinding→ Magnetic Particle Testing→ Packing

| The tests we conduct to ensure best quality | |||

| Chemical Analysis | Metallographic | Mechanical Analysis | Ultrasonic Testing |

| Magnetic Testing | Impact Testing | Hardness Testing | Surface Quality |

| Diemension Checks(CMM) | Customers' acceptance check or third party check | ||

|