| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

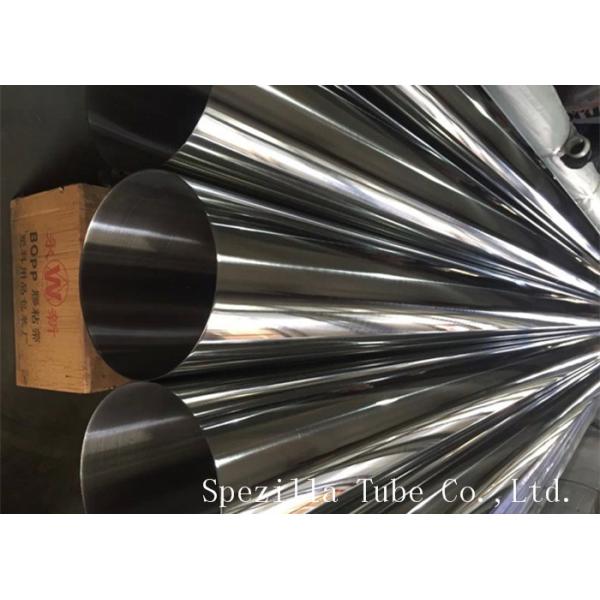

| Categories | High Purity Stainless Steel Tubing |

|---|---|

| Brand Name: | SPEZILLA |

| Model Number: | ASTM A270 ASME SA270 |

| Certification: | ISO9001:2008, PED 97/23/EC |

| Place of Origin: | CHINA |

| MOQ: | Negotiation |

| Price: | Negotiation |

| Payment Terms: | T/T or L/C |

| Supply Ability: | 1000 TONS / MONTH |

| Delivery Time: | 10 DAYS |

| Packaging Details: | PLY-WOODEN CASE / BUNDLE WITH PLASTIC CAP |

| Materials: | AISI TP316L,304L |

| O.D.: | 3/4"-6" |

| W.T.: | 1.65mm,2mm,1.5mm,1.2mm |

| Length: | 20ft |

| Pipe Finish: | Polished |

| Standard: | ASTM A270 |

| Company Info. |

| Spezilla Tube Co., Ltd. (Shanghai) |

| Verified Supplier |

| View Contact Details |

| Product List |

Matte Polished 20ft Fixed Stainless Steel Sanitary Pipe Size 38.1x1.65MM

SPEZILLA is leading manufacturer & suppliers of stainless steel seamless and welded tubing manufactured as per ASTM A270 standards in grades SS304L, 904L, 321, SS316L with bright annealed finish, electropolished finish or mechanical polish & all stainless steel pipes, with strategic inventories for quick call-outs. Spezilla sanitary tube is ideal for the dairy food and beverage industries where the highest degree purity and cleanliness is essential. It is certified to the requirements of ASTM A270 standards, and most user specifications.

304/304L:

304 is the standard '18/8' stainless and known to be the most

versatile and most widely used stainless steel. It is chosen for

its suitability for use in highly corrosive environments,

resistance to chromium carbide precipitation, high formability and

high weldability. 304L grade is an extra low carbon version of 304

which offers additional resistance to carbide precipitation during

welding, therefore eliminating the need for post weld annealing in

most cases. Applications include kitchen equipment, welded

components of chemical, textile, pharmaceutical and paper

processing equipment, cosmetic automotive trim, air bag inflator

tubes, automotive and truck exhaust components.

TP316/316L:

This stainless grade is similar to that of the 304 grade, but with

additions of molybdenum, greater corrosion resistance and improved

high temperature strength is achieved. Corrosion resistance to

lower pH and chloride solutions can be attributed to this

particular grade's combination of stainless alloying elements. 316L

grade is an extra low carbon version of 316 which offers additional

resistance to carbide precipitation during welding, therefore

eliminating the need for post weld annealing in most cases.

Applications include parts exposed to marine atmospheres, furnace

components, heat exchanger tubes, and exhaust manifolds.

Quality Control:

To assure the highest quality standards, our stainless steel sanitary pipe is subjected to extensive testing and inspection programs that meet or exceed ASTM A270/A1016/A1016M test requirements. Testing includes reverse bend, reverse flattening, and flange tests. Eddy current testing is performed on 100% of the stainless steel sanitary pipe produced.

Available Sizes:

OD from 1/2'' to 8'' (12.7MM to 203.20MM)

Wall thickness: 0.065'' to 0.083'' (1.65MM to 2.11MM)

Length: 20ft ( 6100MM)

Surface Polish:

Surface finish is 20 u-in Ra (0.5um) ID maximum, 30 u-in Ra (0.8um) OD maximum surface roughness measured per ASME/ANSI B46.1 with the profilo-meter reading at 90 degree to the lay. Other finishes available upon request.

Applications:

1. Heat Exchangers, Condensers & Pressure Vessels

2. Chemical & Petrochemical

3. Gas Industry

4. Power Generation

5. Pressure Vessels

6. Marine Equipments

7. Food & Beverage Processing

8. Automotive

9. Pulp & Paper

| Grades | TP 304 | TP 304L | TP 316 | TP 316L |

| C max | 0.07 | 0.03 | 0.08 | 0.03 |

| Mn max | 2.00 | 2.00 | 2.00 | 2.00 |

| P max | 0.045 | 0.045 | 0.045 | 0.045 |

| S max | 0.03 | 0.03 | 0.03 | 0.03 |

| Si max | 0.75 | 0.75 | 0.75 | 0.75 |

| Cr | 17.5 -- 19.5 | 17.5 -- 19.5 | 16 -- 18 | 16 -- 18 |

| Ni | 8 -- 10.5 | 8 -- 12 | 10 -- 14 | 10 -- 14 |

| N max | 0.10 | 0.10 | 0.10 | 0.10 |

| Mo | -- | -- | 2.00-3.00 | 2.00-3.00 |

| Size Range Governing Production Specifications - ASTM A270/A269/A249 | |||||||||||||||||||||||

|