| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Bottom Track Rollers |

|---|---|

| Brand Name: | YT |

| Model Number: | ZX210 |

| Place of Origin: | China (Mainland) |

| MOQ: | 1 PCS |

| Price: | Negotiable |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 10000 PCS/Month |

| Delivery Time: | 7-30 Days |

| Packaging Details: | Standard Export Packaging |

| Material: | 50Mn Steel |

| Technique: | Forging/Casting |

| Quality: | Heat Treatment HRC 40-55 |

| Color: | Black or Yellow |

| Features: | Durable |

| Warranty Time: | 12-18 months |

| Shipment: | By Air, Ship |

| Package: | Export Packaging |

| Company Info. |

| XIAMEN YINTAI MACHINERY CO., LTD. |

| Verified Supplier |

| View Contact Details |

| Product List |

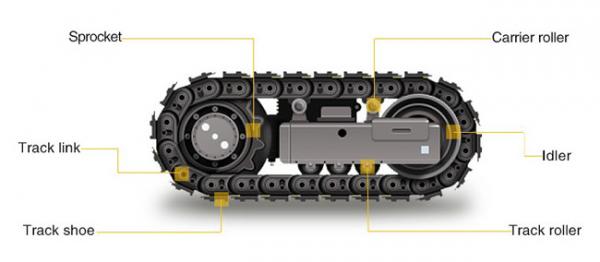

Conveyor belt systems utilize track rollers to bear the weight of both the belt and the conveyed materials. These rollers can be welded using two methods: the traditional approach or friction welding. Friction welding is a solid-phase joining technique that ensures dependable welds and produces joints of superior quality and strength, while minimizing distortion.

* Friction-welding track roller is better in the wear-resistance and has a longer working lifetime.

* Consumption of raw material: the roller bodies of traditional track rollers are connected by the welding rod. but the friction ones are connected by the friction between rollers' bodies. So the friction-welding roller will be added more raw material to make sure the roller is perfect to the standard size after welding.

* Inner parts: For the traditional rollers, the welding is done after two processes of machining, so the size of the inner parts is not so precise as friction-welding ones. For the friction-welding ones, after the welding, there is one more precise machining with concentric loing to make sure the conformity of inner size, this means the inner parts are more precise with a higher standard.

* Single and double-edge track roller suits for er excavating machines and special machinery ranging from 3 to 50 tons.* Double conical sealing and lifelong lubriion designing enable the track roller to have a longer lifetime and perfect performance in any circumstances.

* The shell made by hot forging treatment obtains the superior structure of internal materials and fiber.

* Different quenching or feed-through quenching heat treatment is effective in crack resistance.

6. Hot Sale Products

|