| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Stud And Track Roll Forming Machine |

|---|---|

| Brand Name: | Sussman |

| Model Number: | SM-CM |

| Certification: | CE |

| Place of Origin: | Wuxi Jiangsu China |

| MOQ: | 1 set |

| Price: | USD15000-16500 per set |

| Payment Terms: | T/T L/C, D/P, Western Union, MoneyGram |

| Supply Ability: | 10 sets per months |

| Delivery Time: | 45-55 days after deposit |

| Packaging Details: | Film and Steel |

| Rolling speed: | 10-12m/min(not include cutting time) |

| Rolling thickness: | 3mm |

| Raw material: | Galvanized steel sheet |

| Roller material: | 45#forge steel, coated with chrome |

| Material of chain: | 45# forged steel with frequency quenching, 12A |

| Tolerance: | ±1.5mm |

| Transmission: | By chain 1.5 inch |

| Roller stations: | 13 stations |

| Frame: | H type steel |

| Company Info. |

| Sussman Machinery(Wuxi) Co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

13 Stations Roof Batten Roll Forming Machine For Light Steel

Trusses

Technical Parameter

| Item NO |

|

|

| 1.0 | Roll forming machine | |

| 1.1 | Rolling speed | 10-12m/min(not include cutting time) |

| 1.2 | Rolling thickness | 3mm |

| 1.3 | Raw material | Galvanized steel sheet |

| 1.6 | dimension | 5500×600×1200(mm) |

| 1.7 | Effective width | 91mm |

| 1.8 | Roller stations | 13 stations |

| 1.9 | Roller material | 45#forge steel, coated with chrome |

| 1.10 | Shaft diameter | Φ60mm ,material is 45# forge steel |

| 1.11 | Transmission | By chain 1.5 inch |

| 1.12 | Material of chain | 45# forged steel with frequency quenching, 12A |

| 1.14 | Material of cutting | Cr12Mov with quench HRC58-62° |

| 1.15 | Tolerance | 10m+-1.5mm |

| 1.16 | Frame | H type steel |

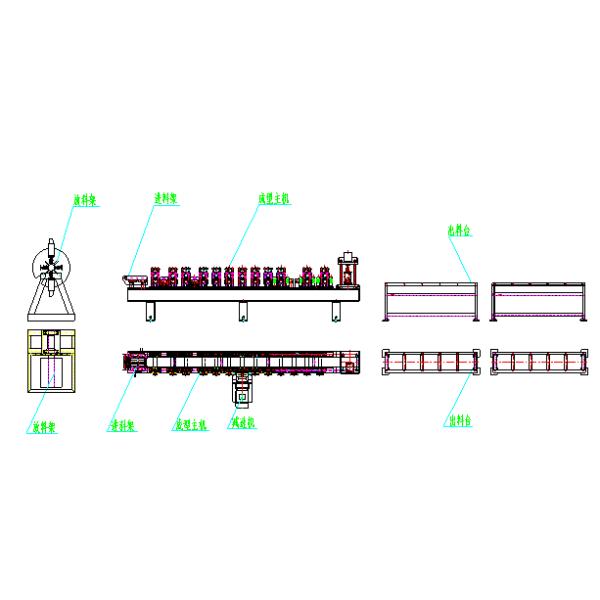

Technological process

Decoiling - Feeding with guide - Roll forming - Cutting - Products

Output

Machine profile

Features and Components of the machine

--Simple structure & beautiful appearance, we adopt the shape-steel

structure and process as a whole after welding. It has the ability

of strong loading and stable operation when running the machine.

--Main parts of machine are famous brand, to ensure the machine

normal function very effectively.

-- Length of panel forming and cutting adopts automatically to

guarantee the length to be precise and the finished product clear

without deforming.

-- Install the equipment and suitable for producing in the factory

easily

-- Low noise and high efficiency.

Loading Photo

|