| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Stainless Steel Bar |

|---|---|

| Brand Name: | UST |

| Model Number: | 300 Series- 303 |

| Certification: | ISO 9001 |

| Place of Origin: | CHINA |

| MOQ: | MOQ: 1/ton |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 1000 Metric Tons per Month |

| Delivery Time: | 5-8 work days |

| Packaging Details: | In standard export packing and seaworthy material with rectangular shape bundle, covered with tarpaulin, in ontainers or in bulk, or upon request |

| Applications: | Nuts and bolts Aircraft fittings Gears Screws Shafts Electrical switchgear components Bushings |

| Techniques:: | Cold Drawn; Hot Rolled; Cold Rolled; Forged |

| Surface:: | Black, Bright, Polished, Peeled, Or Upon Request |

| Quality Inspection:: | SGS, BV Etc. |

| Company Info. |

| SHANGHAI UNITE STEEL |

| View Contact Details |

| Product List |

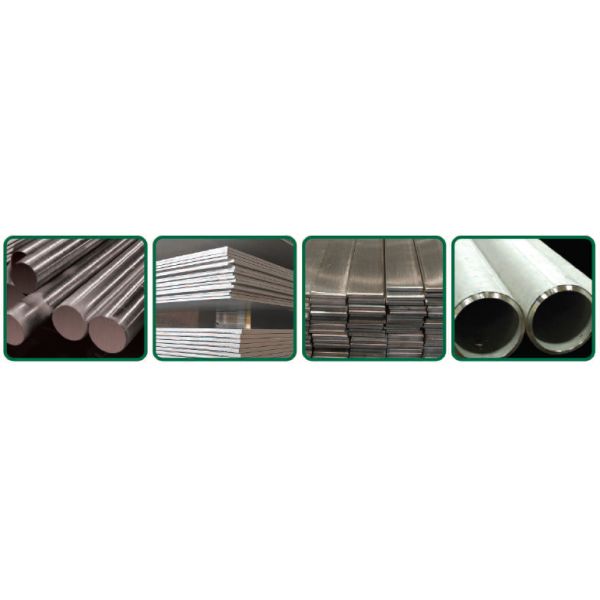

303 Stainless Steel- 300 Series Stainless round bar/ flat bar/ coil

Shanghai unite steel inventory includes 303 grade stainless steel (UNS S30300) in plate, round bar, square bar, hex bar, and rolled flat bar.

Alloy 303 is a non-magnetic, austenitic stainless steel that is not hardenable by heat treatment. It is the free machining modification of the basic 18% chromium / 8% nickel stainless steel. Alloy 303 was specially designed to exhibit improved machinability while maintaining good mechanical and corrosion resistant properties Due to the presence of sulfur in the steel composition, Alloy 303 is the most readily machineable austenitic stainless steel; however, the sulfur addition does lower Alloy 303’s corrosion resistance to below that of Alloy 304. Like other austenitic grades, Alloy 303 demonstrates excellent toughness, although the sulfur does reduce this a little as well.

Alloy 303 is frequently used in applications that require parts to be heavily machined. Some examples include:

ASTM/ASME ……………. UNS S30300

EURONORM ……………. FeMi35Cr20Cu4Mo2

DIN ………………………… 2.4660

| % | Cr | Ni | C | Si | Mn | P | S | Mo | Fe |

|---|---|---|---|---|---|---|---|---|---|

| 303 | min: 17.0 max:19.0 | min: 8.0 max: 10.0 | 0.15 max | 1.00 max | 2.0 max | 0.20 max | 0.15 min | 0.75 | balance |

| Grade | Tensile Strength ksi (min.) | Yield Strength 0.2% Offset ksi (min.) | Elongation - % in 50 mm (min.) | Hardness (Brinell) MAX | Hardness (Rockwell B) MAX |

|---|---|---|---|---|---|

| 303 | 75 | 30 | 35 | 228 |

| Denstiy lbm/in3 | Coefficient of Thermal Expansion (min/in)-°F | Electrical Resistivity mW-in | Thermal Conductivity BTU/hr-ft-°F | Melting Range | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| at 68 °F | at 68 – 212°F | at 68 – 932°F | at 68 – 1450°F | at 68°F | at 212°F | at 392°F | at 752°F | at 1112°F | at 1472°F | at 68 – 212°F | |

| 0.29 | 9.2 | 10.4 | 10.9 | 28.3 | 30.7 | 33.8 | 39.4 | 43.7 | 47.6 | 113.2 | 2552°F |

|