| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Tungsten Carbide Rod |

|---|---|

| Brand Name: | Zhuzhou Jintai Cemented Carbide |

| Model Number: | Various |

| Place of Origin: | Hunan, China |

| MOQ: | 1 - 500 Kilograms sample order acceptable |

| Price: | Negotiable, depends on carbide grade and quantity. |

| Supply Ability: | 300 Ton/Tons per Month |

| Packaging Details: | Pack with shock resistance foam first in plastic box, and then carton boxes outside. Or pack according to your request |

| Certification: | SGS |

| Payment Terms: | Western Union, L/C, T/T |

| Delivery Time: | 7-25 days, depends on quantity. |

| Alloy Specification: | YG6X/YG8/YL10.2 ETC... |

| Particle: | 0.2-1.7um |

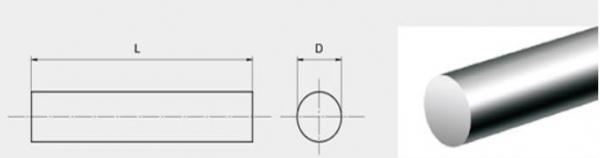

| Product name: | cemented carbide rods yl10.2 solid tungsten carbide round bars |

| Material: | 100% virgin carbide material |

| Surface: | High Polished |

| Certificate: | ISO |

| Type: | Power Tool Parts |

| Application: | for carbide tipped annular cutter |

Features of tungsten carbide rod:

As for tungsten carbide rod, below are the general features for

your reference

For more details of specific type, please inform us:

1. Better wear resistance, higher toughness, better deformation and

fracture resistance, results in a long life and good size accuracy

2. Adopt advanced automatic extrusion equipment

3. HIP sintering and precision grinding to ensure the good

performance

4. Both blank and finished tungsten carbide rods available

5. Can reach a mirror effect surface after accurate grinding and

polishing

| Properties of cemented carbide grades for recommended rods | |||||||

| Grade | Chemical composition | Physical data | Grain size of WC(um) | ||||

| WC | Co | Others | Density(g/cm³) | Hardness(HV3) | TRS(MPa) | ||

| YL10.1 | 93.50% | 6.00% | 0.50% | 14.88-15.04 | 1580±50 | 2500 | 1.2-1.7 |

| YL10.2 | 89.50% | 10.00% | 0.50% | 14.4-14.55 | 1600±50 | 4000 | 0.8 |

| YL10.5 | 89.70% | 9.50% | 0.80% | 14.4-14.55 | 1550±50 | 3800 | 0.7-0.9 |

| YL50 | 85.00% | 15.00% | 13.86-14.10 | 1095 | 2060 | 0.4-0.6 | |

| YU06 | 93.00% | 6.00% | 1.00% | 14.7-14.8 | 2050 | 3000 | 0.2-0.4 |

| YU08 | 91.00% | 8.00% | 1.00% | 14.56-14.65 | 1900 | 4000 | 0.2-0.4 |

| YU09 | 89.80% | 9.00% | 1.20% | 14.36-14.50 | 1950 | 3900 | 0.2-0.4 |

| YU12 | 87.00% | 12.00% | 1.00% | 14.05-14.15 | 1750 | 4000 | 0.2-0.4 |

| YF06 | 93.50% | 6.00% | 0.50% | 14.86-14.96 | 1800 | 3800 | 0.4-0.6 |

| YF08 | 91.40% | 8.00% | 0.60% | 14.55-14.65 | 1800 | 3900 | 0.4-0.6 |

| YG6X | 93.50% | 6.00% | 0.50% | 14.8-15.10 | 91 | 1560 | 1 |

| YG8 | 92.00% | 8.00% | 14.6-14.9 | 89.5 | 1840 | 1.2-1.6 | |

~ Customized Tungsten carbide products are available!

| Type | D(mm) | Tol. Of diameter(mm) | L(mm) | Tol. Of diameter(mm) |

| ¢1.0*330 | 1.0 | +0.2~+0.45 | 330 | 0~+5.0 |

| ¢2.0*330 | 2.0 | +0.2~+0.45 | 330 | 0~+5.0 |

| ¢3.0*330 | 3.0 | +0.2~+0.45 | 330 | 0~+5.0 |

| ¢4.0*330 | 4.0 | +0.2~+0.45 | 330 | 0~+5.0 |

| ¢5.0*330 | 5.0 | +0.2~+0.45 | 330 | 0~+5.0 |

| ¢6.0*330 | 6.0 | +0.2~+0.45 | 330 | 0~+5.0 |

| ¢7.0*330 | 7.0 | +0.2~+0.45 | 330 | 0~+5.0 |

| ¢8.0*330 | 8.0 | +0.2~+0.45 | 330 | 0~+5.0 |

| ¢9.0*330 | 9.0 | +0.2~+0.45 | 330 | 0~+5.0 |

| ¢10.0*330 | 10.0 | +0.2~+0.5 | 330 | 0~+5.0 |

| ¢11.0*330 | 11.0 | +0.2~+0.5 | 330 | 0~+5.0 |

| ¢12.0*330 | 12.0 | +0.2~+0.5 | 330 | 0~+5.0 |

| ¢13.0*330 | 13.0 | +0.2~+0.5 | 330 | 0~+5.0 |

| ¢14.0*330 | 14.0 | +0.2~+0.5 | 330 | 0~+5.0 |

| ¢15.0*330 | 15.0 | +0.2~+0.6 | 330 | 0~+5.0 |

| ¢16.0*330 | 16.0 | +0.2~+0.6 | 330 | 0~+5.0 |

| ¢17.0*330 | 17.0 | +0.2~+0.6 | 330 | 0~+5.0 |

| ¢18.0*330 | 18.0 | +0.2~+0.6 | 330 | 0~+5.0 |

| ¢19.0*330 | 19.0 | +0.2~+0.6 | 330 | 0~+5.0 |

| ¢20.0*330 | 20.0 | +0.2~+0.7 | 330 | 0~+5.0 |

| ¢21.0*330 | 21.0 | +0.2~+0.7 | 330 | 0~+5.0 |

| ¢22.0*330 | 22.0 | +0.2~+0.7 | 330 | 0~+5.0 |

| ¢23.0*330 | 23.0 | +0.2~+0.7 | 330 | 0~+5.0 |

| ¢24.0*330 | 24.0 | +0.2~+0.7 | 330 | 0~+5.0 |

| ¢25.0*330 | 25.0 | +0.2~+0.7 | 330 | 0~+5.0 |

| ¢26.0*330 | 26.0 | +0.2~+0.8 | 330 | 0~+5.0 |

| ¢27.0*330 | 27.0 | +0.2~+0.8 | 330 | 0~+5.0 |

| ¢28.0*330 | 28.0 | +0.2~+0.8 | 330 | 0~+5.0 |

| ¢29.0*330 | 29.0 | +0.2~+0.8 | 330 | 0~+5.0 |

| ¢30.0*330 | 30.0 | +0.2~+0.8 | 330 | 0~+5.0 |

|