| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Printer Slotter Machine |

|---|---|

| Brand Name: | KECHENG |

| Model Number: | KC-H1632 |

| Certification: | CE |

| Place of Origin: | CHINA |

| MOQ: | 1 sets |

| Price: | Negotiated |

| Payment Terms: | L/C,TT |

| Supply Ability: | 200 sets per year |

| Delivery Time: | 65 working days |

| Packaging Details: | Plastic film packaging and cartons |

| Name: | Printing Slotting Die Cutting Machine |

| Application: | Corrugated carton printing die cutting |

| Printing type: | Flexo top printing |

| Ink: | Water ink |

| Power: | Customized (220V/380V/420V) |

| Bearings: | NSK/NTN/HRB |

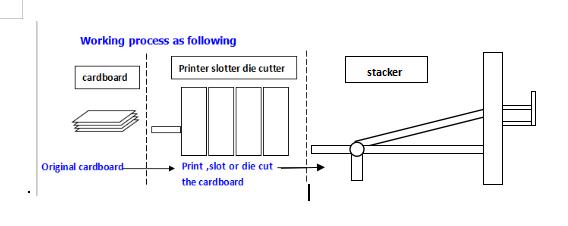

Automatic Top Printing Roller Transfer 3 Color Carton Box Flexo

Printing Die Cutting Machine

Automatic Top Printing Roller Transfer Carton Box Flexo Printing

Die Cutting Machine used for corrugated carton box making

companies, 1) The machine is lead edge feeding, with high speed

2)the machine has roller transfer printing unit and vacuum transfer

printing unit for option .3) Automatic ink washing system for

option will save water and ink. 4) rubber roller ink distribution

and Doctor blade chamber ink distribution for option. 5)All the

rollers, gears and main parts undergoes precise treatment to make

sure running stable and printing precise.6)easy to operate and

maintain.7)We have professional and experienced after sale team for

solving machine problems

Technologic parameter

| Model | KC-H618 | KC-H 920 | KC-H1224 | KC-H1628 | KC-H1632 |

| Max feeding size | 600*1900mm | 900*2100mm | 1200*2500mm | 1600*2900mm | 1600*3300mm |

| Min feeding size | 220*600mm | 300*650mm | 400*720mm | 450*750mm | 450*750mm |

| Max printing size | 550*1800mm | 880*1000mm | 1150*2400mm | 1550*2800mm | 1550*3200mm |

| Skip feeding size | 800*1900mm | 1100*2100mm | 1400*2500mm | 1800*2900mm | 1800*3300mm |

| Max speed | 350pcs/min | 300pcs/min | 250pcs/min | 180pcs/min | 180pcs/min |

| Registering | +/-0.5mm | +/-0.5mm | +/-0.5mm | +/-0.5mm | +/-0.5mm |

| Min slotting gap | 240*60*240*60mm | 250*70*250*70m | 270*80*260*80mm | 280*100*280*100mm | 280*100*280*100mm |

| Slotting precise | +/-1.5mm | +/-1.5mm | +/-1.5mm | +/-1.5mm | +/-1.5mm |

| Die cutting precise | +/-1.5mm | +/-1.5mm | +/-1.5mm | +/-1.5mm | +/-1.5mm |

Feeding Unit

• Lead edge feeder.

• Automatic feeding stroke of “Sun Automation” gear box.

• Maximum speed up to 350sheets per minute.

• Automatically adjust air vent of feeding chamber.

Pringing Unit (Top printing)

• Printer unit by roller transfer or vacuum transfer for option.

• Automatic pneumatic lifting gear working with feeding system(Anilox

roller lowers down to touch printing template during feeding and

rises up to leave printing template after stopping feeding.)

• Ceramic anilox roller with doctor blade champer or rubber roller

ink distribution for option

• Printing phase adopts PLC, touch screen control and electric

numerical inverter adjustment of 360o.(running and stopping can be adjusted)

• Automatic reposition after washing the printing template during

the printing procession.

Slotting Creasing Unit

• Double slotting shafts & double creasing shafts for option

• Enlarge crusher and creaser for getting effective scoring line.

• Stainless strip of defecator for slotting waste paper extrusion.

• Automatic reposition after washing the printing template during the

printing procession.

•Alloy steel double-blade trimming knife after heat treatment with sharp edge can make high precision.

•Slotting phase adopts PLC, touch screen control and electric numerical inverter adjustment of 360o.(running and stopping can be adjusted)

Die Cutting Unit

• Anvil trimming device installed.

• Motorized movement Aluminum circle on die drum.

• Anvil drum oscillation via hydraulic cylinder.

• Waste conveyor underneath die cutter units.

Stacker Machine

• Option for mechanical or hydraulic operation

• Height of piling is 1600mm.

• Added with safety facility to control the lifting of machine and

secure the worker.

• Climbing belt with wrinkled surface prevents sliding of paperboard.

• Back baffle position is adjusted by manual control.

|