| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Hot Rolled Alloy Steel |

|---|---|

| Brand Name: | CF STEEL |

| Model Number: | 1.2083 SUS420J2 420 S136 4Cr13 |

| Certification: | ISO/Mill Certificate/SGS |

| Place of Origin: | China |

| MOQ: | Negotiable |

| Price: | Negotiable |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 3000t/Month |

| Delivery Time: | 7-15 days |

| Packaging Details: | standard export packing or customers' request. |

| Standard: | DIN,ASTM,AISI,GB,JIS |

| Surface treatment: | Black / Milling / Machined |

| Hardness: | Pre-hardened HRC 30-36; Annealing <235 |

| Test: | SGS / Ut 100% / Element Testing |

| Heat Treatment: | Annealing +Q+T |

| Technology: | Forged or Hot Rolled |

Black Surface of Hot Rolled Stainless Steel Plate 1.2083 S136 4Cr13

1.2083 mould steel is a kind of plastic mould steel with high

chromium element which is up to 13%.1.2083 mould steel has good

wear resistance and good polishing, it widely used for acid proof

plastic mold.

Grades Comparison

| Germany(DIN) | Japan(JIS) | USA(AISI) | Sweden(SS) | China(GB) |

| 1.2083 | SUS420J2 | 420 | S136 | 4Cr13 |

Avaialbe Size

| Steel plate | Thickness | Width | Length |

| 10-195mm | 205-2000mm | 1600-6000mm |

Chemical composition (%)

| Grade | delivery hardnessºC | C | Si | P | S | Cr | Ni | Mo | Mn |

| 420 | HRC32-36 | 0.4 | 0.8 | ≤0.03 | ≤0.03 | 13.5 | ~ | 0.6 | 0.5 |

| 4Cr13 | HB≤201 | 0.36-0.48 | ≤0.6 | ≤0.035 | ≤0.03 | 12-14 | ≤0.6 | ~ | ≤0.8 |

| 1.2083 | HB≤235 | 0.26-0.35 | ≤0.6 | ≤0.03 | ≤0.03 | 12.5-14 | ≤0.5 | ~ | ≤0.8 |

| S136 | HB≤235 | 0.38 | 0.8 | ≤0.03 | ≤0.03 | 13.6 | ~ | ~ | 0.5 |

Recommend heat treatment:

| Heating temperature/ºC | Cooling way | Hardness(HRC) | Tempering temperature /ºC | Hardness(HRC) | |

| Preheating temperature | Solution temperature | ||||

| 920-980 | 1050-1100 | Oil Cooling | 48-54 | 200 | ≥48 |

Package: Standard export packing or according to customers' request.

Features:

1) Excellent corrosion resistance;Excellent abrasion resistance and

elasticity;

2) Excellent high-temperature abrasion resistance;

3) medium toughness,d imensionally stable, high compressive

strength;

Application:

1) highly stressed cutting and punching tools for thin sheets;

2) stone processing tools and knives for paper and plastics, shear

knives

3) Chemical Resistance plastic mold, Corrosion of thermoplastic

plastics;

Delivery: For abundant stock, 7-15 days.For customized products, 30-50 days.

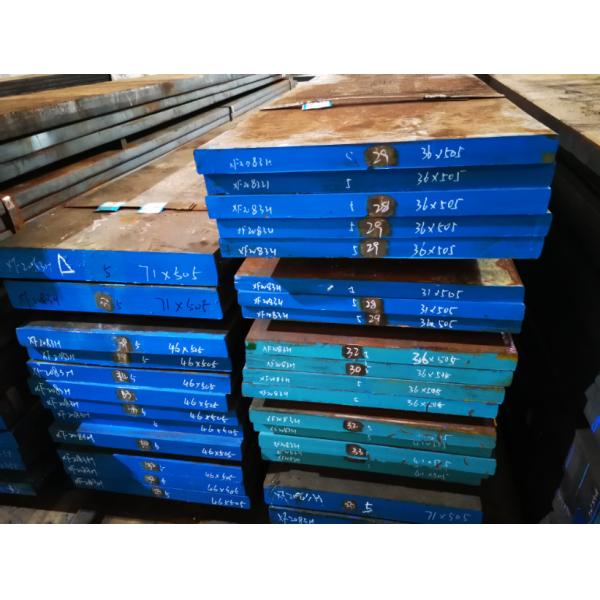

Product Photo

Strict Quality Control

Loading Photo

Changfeng Steel hot sale product:

| STANDARD/GRADE | Flat Bar Size(mm) | Round bar Size(mm) | Technics | ||||||

| DIN | AISM | JIS | GB(China) | Thickness | Width | Length | Diameter | Length | |

| 1.121 | SAE1050 | S50C | 50# | 10-450 | 155-2200 | 2000-12000 | Forged, Hot Rolled | ||

| 1.2311 | P20 | PDS-3 | 3Cr2Mo | 10-460 | 155-2200 | 2000-10000 | 20-200 | 2000-6000 | |

| 1.2738 | P20+Ni | - | 3Cr2NiMnMo | 21-300 | 155-2200 | 2000-8000 | 20-200 | 2000-6000 | |

| 1.2379 | D2 | SKD10 | SKD10 | 10-200 | 155-810 | 2000-6000 | 14-80 | 3000-6000 | |

| 1.2080 | D3 | SKD1 | 3Cr2Mo | 10-200 | 155-810 | 2000-6000 | 20-200 | 3000-6000 | |

| 1.2083 | 420 | - | 4Cr13 | 10-500 | 155-1200 | 2000-6000 | 12-300 | 3000-6000 | |

| 1.2344 | H13 | SKD61 | 4Cr5MoSiV1 | 10-500 | 155-1600 | 2000-6000 | 16-400 | 3000-6000 | |

| 1.2510 | O1 | SKS3 | 9CrWMn | 10-200 | 155-810 | 2000-6000 | 20-200 | 3000-6000 | |

| 1.7225 | SAE4140 | SCM440 | 42CrMo | 10-280 | 155-2200 | 2000-6000 | 16-450 | 3000-6000 | |

|