| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Castings And Forgings |

|---|---|

| Brand Name: | ZTIC |

| Model Number: | Castings And Forgings |

| Certification: | ISO/CE |

| Place of Origin: | Henan, China |

| MOQ: | >=1 Sets |

| Price: | negotiable |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 5000.0 Set/Sets per Year |

| Packaging Details: | Standard packing or according to customer's requirement |

| Product Name: | Slag pot,slag bowl,slag ladle |

| Appro.Net weight: | 10 -100 t |

| Application: | Metallurgy, chemical industry |

| Fact cubage(CBM): | 22 |

| Quality Control: | Professional Inspection |

| Smelting and casting process: | Cupola smelting, single bale pouring |

| Product application: | Steel works |

| Classification: | Castings And Forgings |

| Warranty: | 12 months |

| Company Info. |

| Luoyang Zhongtai Industries CO.,LTD |

| Verified Supplier |

| View Contact Details |

| Product List |

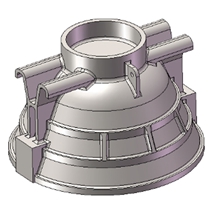

Metallurgical Castings And Forgings Slag Pot Slag Bowl Slag Ladle

1. Metallurgical slag ladle castings and forgings product introduction

Slag ladle is the equipment used to load slag before steelmaking furnace. Its use environment is bad, it is changeable when heated, and it requires high use times. The larger the slag ladle volume, the more difficult it is to cast.

Slag ladle is the place where iron and slag are produced. The modern blast furnace iron extraction field is equipped with mud gun (plugging machine), opening machine, swing flow groove, crane, iron tank, slag ladle and other equipment. The mud cannon was pneumatic, then electric.

2. Smelting and casting process of metallurgical slag ladle castings and forgings

Cupola smelting, single bale pouring, first fast then slow, one pouring.

3.Slag pot,slag bowl,slag ladle castings and forgings technical parameters

| Product name | Slag pot,slag bowl,slag ladle castings and forgings |

| Material | DIN 17182 GS-16Mn5 1.1131 |

| Fact cubage | 22 CBM |

| Appro.Net Wt | 10 -100 t |

| Product application | Steel works |

| OEM service offered | According to customer’s drawings |

4. Principle of slag ladle

Slag ladle is mainly used for bearing converter slag, refining slag and continuous casting of large bales and so on. Under the condition of steel slag in converter smelting process temperature is higher than the temperature of the liquid steel (because the steel slag is located in the high temperature of oxygen blowing reaction area), after the smelting in converter slag splashing process, the composition such as falls or furnace slag, such as operation, can make cover on the surface of the liquid steel, a drop in the temperature of the liquid steel slag, in theory, such a high temperature molten steel slag have to wear the risk of slag pot. But the slag film once formed, combined with cast steel material possesses the advantages of fast heat fast, thermal conductivity, slag pot body surface to convection, will therefore not be slag pot red deformation caused by the temperature too high, the temperature of the tank of liquid steel slag and slag is gradually reduced, so the slag film is hard to melt, it is fully guarantee the safety of slag ladle has enough. Of course, if the high temperature molten steel continues to enter the slag ladle before the steel slag, its impact kinetic energy and high temperature are likely to cause the slag ladle penetration accident; On the other hand, if the slag enters the slag ladle first, then the risk of wearing the tank is much smaller, which is also the technical principle of casting steel slag ladle can safely carry high temperature steel slag.

FQA

Q: Why we believe in luoyang zhongtai industries co., ltd:

A: 1. More than 30 years experience.

2.We are the leading professional supplier of mining machinery, construction machinery, machines casting and forged parts.

3. All products achieved ISO9901:2000 quality management certificate and CE, ROHS certificates.

Q:Delivery time :

A: Parts lead time 1-2months, machines 2-3months.

Q:Payment terms :

A: Accept payment type: T/T, L/C, Western union,Cash. 30% deposit when signed contract. Full payment paid before shipping.

Q: Quality warranty?

A: Guarantee time: one year for main machinery. If something wrong we will provide the technical advice and find solution immediately. For those wearing parts we guarantee high quality parts for long-term supply.

Q: After sales service?

A: We can supply technical guide for machines running test and parts maintenance if end user needs.

|