| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Bending Sheet Metal Parts |

|---|---|

| Brand Name: | PFT |

| Model Number: | OEM |

| Certification: | ISO9001:2015, ISO13485:2016 |

| Place of Origin: | Guangdong, China |

| MOQ: | 1PC |

| Price: | Negotiable |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 10000Pcs/ Month |

| Delivery Time: | 7-15 work days |

| Packaging Details: | As the requirement of customer |

| Material: | Stainless Steel |

| Size: | Custom size |

| Service: | OEM/ODM |

| Surface treatment: | Powder Coating |

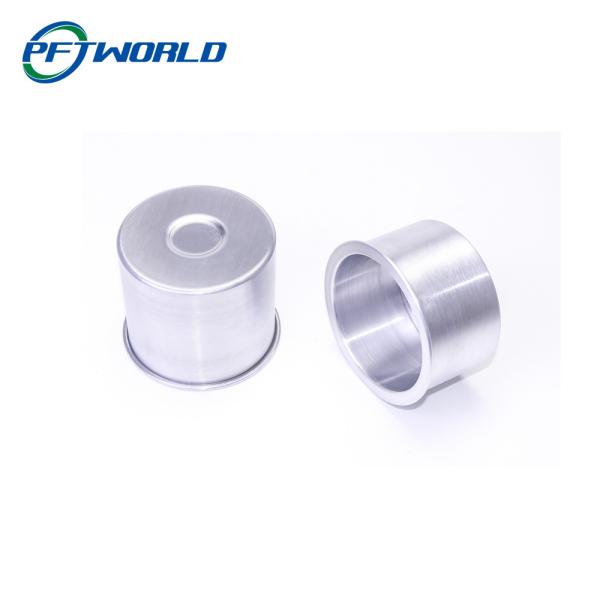

| Product name: | Custom Sheet Metal Fabrication Parts |

| Technology: | 15 Years Experience |

| Diameter: | 0.325inch, 0.13inch |

| Fine Blanking: | Multi-Position |

| Acceptable: | OEM/ODM |

| Industry: | Steel Fabrication |

| Item: | Machining Mental Parts |

| Processing: | Bending, Punching, Cutting, Etc. |

| Process: | Bending |

| Weight: | Lightweight |

| Cutting Thickness: | Materials |

| Finish: | Customer request |

| Thickness: | 0.1mm-12mm |

| Company Info. |

| Shenzhen Perfect Precision Product Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

In today’s fast-moving industries—from electronics to automotive to consumer products—precision metal components are a key part of how things work. And when it comes to strength, durability, and clean finish, bending sheet metal parts and stainless steel stamping accessories are often the go-to choice for manufacturers worldwide.

What Are Bending Sheet Metal Parts?

Sheet metal bending is exactly what it sounds like—taking a flat piece of metal and shaping it into a functional form using pressure and tooling. These parts are often used in:

The beauty of bending is that you get strong, lightweight parts with high dimensional accuracy. Whether it’s a simple angle or a complex multi-bend component, the process ensures consistent results.

Why Stainless Steel?

When you need toughness and a clean finish, stainless steel is the material to beat. It’s:

Stainless steel bending and stamping are commonly used in electronics, kitchen equipment, medical devices, and industrial machinery—anywhere performance and appearance matter.

Stainless Steel Stamping Accessories

Stamping is the process of forming parts by pressing sheet metal with a die. It’s used to create complex shapes quickly and accurately. Stainless steel stamping accessories can include:

These accessories are small but critical—they hold devices together, maintain electrical contact, and contribute to a product’s overall design and function.

Benefits of Custom Sheet Metal Work

1.Precision and Repeatability

Once your design is set, every part is made exactly the same, ensuring perfect fit and function.

2.Cost-Effective for High Volumes

Stamping and bending are fast processes, making them ideal for large-scale production.

3.High Strength-to-Weight Ratio

Sheet metal parts are strong without being bulky—perfect for compact, lightweight designs.

4.Versatile Design Options

You can work with various thicknesses, finishes, and configurations to match your exact needs.

Final Thoughts

Whether you’re building electronics, industrial equipment, or consumer goods, using bending sheet metal parts and stainless steel stamping accessories gives you a reliable foundation. These components offer the durability, precision, and clean design your products need to compete in today’s market.

1. Are you a manufacturer or a trading company?

|