| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Granite Surface Plate |

|---|---|

| Brand Name: | FMS |

| Model Number: | custom-made |

| Certification: | CO |

| Place of Origin: | China |

| MOQ: | 5 |

| Price: | Negotiable |

| Payment Terms: | T/T, Western Union, MoneyGram |

| Supply Ability: | 100PC /30days |

| Delivery Time: | 10 work days |

| Packaging Details: | wooden |

| Material: | black granite |

| application: | high precision industry |

| Tolerance: | 00 grade |

| HS Code: | 90179000 |

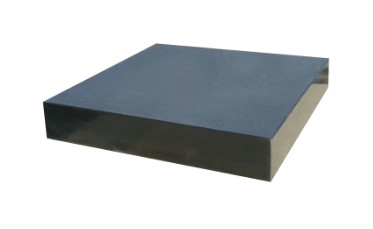

| name: | 1000 X 1000 DIN 876 Black Granite Surface Plate Grades 00 |

| Measure Method: | Manual |

| Optional accessory: | stand for granite surface plate |

| Standard: | DIN876 II |

| Usage: | Laboratory Measuring Tool |

| Company Info. |

| Cangzhou Famous International Trading Co., Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

Granite Surface Plate

Granite Surface Plates are used for precision gauging, inspection,

layout and marking purposes. They are preferred by Precision Tool

Rooms, Engineering Industries and Research Laboratories because of

their following outstanding advantages.

*Well-selected granite materials

*Nice stableness.

*High intensity and rigidity

*Grade 1, 0, 00 are available.

*T-slots or thread holes can be made according to the requirements

* A surface plate made from fine-grained black granite

* This material has many advantages compared to cast iron in this

application, such as being non-magnetic, rustless, twice as

hard, non-burr-forming and not prone to stickiness

* Stress relieved for maximum stability

* Harder than steel

* Non-magnetic and electrically non conducting

A granite surface plate is needed in your workshop to aid with sharpening tools when a flat reference point is required, it is also useful when marking out or checking the flatness of your tools or work. Because the plate is made of solid granite it will not rust or corrode and it is guarenteed not to warp or deform over time

(d is the length of the diagonal)

Specification | Weight (kgs) | Precision Grade (μm) | |||

000 | 00 | 0 | 1 | ||

300 × 200 × 50 | 17 | 1.5 | 3 | 6 | 12 |

300 × 300 × 50 | 19 | 1.5 | 3 | 6 | 12 |

400 × 300 × 70 | 25 | 1.5 | 3 | 6 | 12 |

400 × 400 × 70 | 48 | 2 | 3.5 | 6.5 | 13 |

630 × 400 × 100 | 76 | 2 | 3.5 | 7 | 14 |

630 × 630 × 100 | 155 | 2 | 4 | 8 | 16 |

800 × 500 × 130 | 156 | 2 | 4 | 8 | 16 |

1000 × 630 × 130 | 284 | 2.5 | 4.5 | 9 | 18 |

1000 × 750 × 150 | 338 | 2.5 | 5 | 9 | 18 |

1000 × 1000 × 150 | 450 | 2.5 | 5 | 10 | 20 |

1600 × 1000 × 200 | 963 | 3 | 6 | 12 | 24 |

2000 × 1000 × 200 | 1200 | 3.5 | 6.5 | 13 | 26 |

1600 × 1600 × 300 | 2312 | 3.5 | 6.5 | 13 | 26 |

2000 × 1600 × 300 | 2890 | 3.5 | 7 | 14 | 28 |

2500 × 1600 × 300 | 3612 | 4 | 8 | 16 | 32 |

3000 × 2000 × 500 | 9030 | 4.5 | 9 | 18 | 36 |

4000 × 2000 × 500 | 12040 | 5.5 | 11 | 22 | 44 |

6000 × 2000 × 700 | 25284 | 7.5 | 15 | 30 | 60 |

|