| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

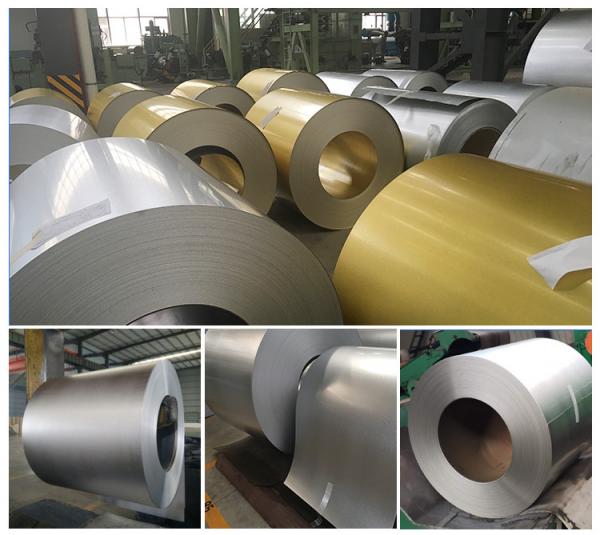

| Categories | Prepainted Aluminum Coil |

|---|---|

| Brand Name: | JBHD |

| Model Number: | DX54D, S220GD, S250GD |

| Certification: | CE、ISO、SGS |

| Place of Origin: | China |

| MOQ: | 1 ton |

| Price: | Negotiation |

| Payment Terms: | T/T, L/C, Western Union, MoneyGram |

| Supply Ability: | 10000 Ton |

| Delivery Time: | 7-15 working days |

| Packaging Details: | Standard seaworthy package |

| Oiled or Non-oiled: | Slightly Oiled |

| Coating: | AZ41-AZ150 |

| Color: | RAL Color |

| Technique: | Cold rolled/Hot Rolled |

| Tolerance: | ±1% |

| Processing Service: | Bending, Welding, Decoiling, Cutting, Punching |

Color Coated Aluminum Coil And Ppgl Galvalume Steel Coil

Can Galvalume touch aluminum?

When used in mild-to-moderately corrosive environments and/or mild-to-moderate humidity, contact between a galvanized surface and aluminum is unlikely to cause substantial incremental corrosion.

Should you paint Galvalume?

It can be painted if a painted appearance is desired with many of the paints which are recommended for galvanized sheet. To paint Galvalume good coating practice should be observed as with painting any surface. The areas to be painted should be dry and clean of visible soil, grease, oil or other contaminants.

Is Galvalume strong?

Galvalume and Galvalume Plus are highly resistant to rust, weather elements and fire and they also provide a very strong protective covering. Compared to galvanized steel, Galvalume is more resistant to corrosion. Both are available with coating or bare.

Is Galvalume an alloy?

The alloy-coated product contains 55% aluminium, 43.5% zinc and 1.5% silicon by weight. Made with the traditional hot-dipping process, Galvalume is a suitable match for applications that demand high corrosion resistance and heat reflectivity.

Standard: | AISI,ASTM,BS,DIN,GB,JIS |

Brand Name | SHANDONG BLUESCOPE NEW MATERIAL CO., LTD. |

Thickness | 0.17mm-0.8mm |

Length | As request |

Width | 760mm to 1250mm |

Surface Treatment | pre-painted/color coated |

Color | As request (All RAL Colors) |

Zinc coating | 40-180g/M² |

Coat | 2/1 (two coats for Front, one coat for Back) {25±5μm on front

coating and 7± 2μm on back coating} |

Base material | GL, or AL-ZINC steel |

Delivery Detail | within 7-25 days after receiving pre-payment (as per the order

quantity) |

Product Advantages

1. Cheap: The cost of aluminized zinc is lower than that of other

coatings.

2. Reliable: The aluminized zinc coating is metallurgically bonded

to the steel and forms part of the steel surface,so the coating is

more durable.

3. Strong toughness: The aluminized zinc layer forms a special

metallurgical structure that can withstand mechanical damage during

transportation and use.

4. Comprehensive protection: Every part of the plated piece can be

aluminized zinc, and is fully protected even in depressions, sharp

corners and hidden places.

5. Save time and energy: Aluminized zinc process is faster than

other coating methods.

Product Application

Aluminized zinc steel coil products are mainly used in

construction, light industry, automobile, agriculture, animal

husbandry, fishery and other industries. Such as building roofs,

highway guardrails, sheet metal processing, roof grilles, household

appliance enclosures, ventilation ducts, chimneys, kitchen

utensils, grain storage and transportation, frozen processing of

meat and aquatic products, etc.

|