| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Horizontal Bead Mill |

|---|---|

| Brand Name: | AllWin |

| Model Number: | SP50, SP100, SP250 |

| Certification: | ISO9001 |

| Place of Origin: | China |

| MOQ: | 1-5sets |

| Price: | USD28000-60000/set |

| Payment Terms: | T/T, MoneyGram, Western Union |

| Supply Ability: | 30sets /month |

| Delivery Time: | 20-30 Working Days |

| Packaging Details: | Wooden boxes |

| Power: | 22KW, 30KW, 37KW,55 KW, 75KW |

| Voltage: | 380 V/220V/415V |

| Litre: | 50/100/250L |

| Disperser's material: | stainless steel, 9Cr18Mo alloy steel, PU coated with stainless steel |

| Motor: | Ex-proof or non ex-proof motor |

| Disperers' structure: | disc type, or disc combined with turbine(complex disc type)) |

| Outter chamber material: | Stainless Steel |

| Application: | Chemical Fiber |

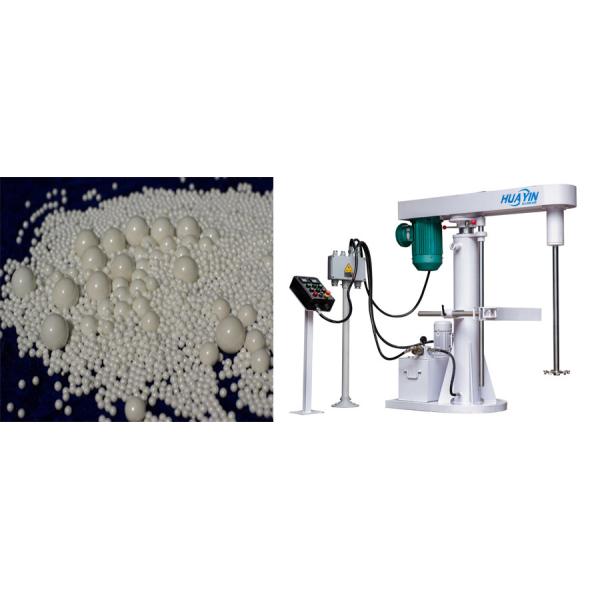

High Production Energy Saving PU Coated Complex Disc Type Horizontal Bead Mill For Wet Slurry Grinding

Grinding is a very important part of fiber processing , and sand grinding mills are the significant fator for the quality of papers. Therefore, it's rather crucial to choose the proper mills.

Most bead mills are suggested according to customer's different requirement and capability, and finally customers get great usage experience, allwin also win great reputation in peers and customers.Inner cylinder, it's an very important parts of grinding with massive touching space when operation, we often advice according to following referrence.

1. ceramics cylinder bead mill with high efficiency, lower temperature is suitable for customers with high standard and longterm vision;

2. bead mills with inner cylinder material 9Cr18Mo wearable stainless steel is more suitable for normal standard products;

3. the PU coated with stainless steel mills are much fitable for no pollution griniding with comparatively higher temperature.

All of them are reasonable, just choose the right mills. All mills owns one year warranty, vulnerable spare parts are exclusive. The motor power can be choosed by your decision or our enginner's consideration.

All of them are reasonable, just choose the right mills. All mills owns one year warranty, vulnerable spare parts are exclusive. The motor power can be matched with parameters. All the operations for operator is easy, and the operation experience is reflected greatly.

The mian feactures:

1. Extend service life: processing with high advanced equipment,operating without runout

2. Decrease the temperature:choosing the proper materials,and also special and mature cooling system

3. Strenghten the fineness:mastering the core grinding and dispersing technology, calculating the proper screenring gaps and matched grinding medium size

4. Enhance the efficiency: considering 5-12 factors influencing the grinding elements comprehensively

5. Lessen the personnels:increasing alarming indicators

Main instructions:

| No | Main parts | SP series | Notes |

| 1 | Outer cylinder | 304 stainless steel | |

| 2 | Internal cylinder | 9Cr18Mo wearing-resistant alloy steel, stainless steel, ceramics, pu coated with stainless steel | others you required |

| 3 | Dispersing shaft | 40Cr with hard chromium plating | Brand: NSK |

| 4 | Dispersing disk | 304 Stainless steel | |

| 5 | Mechanical seal | Double Mechanical seal | |

| 5 | Feeding and discharging end covers on the cylinder | 304 stainless steel | |

| 6 | Turbine centrifugal separator and pegs | 304 stainless steel and YG6 pges | |

| 7 | Static discharge screen ring | 304 stainless steel screen ring with 304. | gaps can be calculated based on grinding medium size or fineness requirement |

| 8 | Mechanical seal | Intelligent double mechanical seal with mandatory lubricating-cooling system | |

| 9 | Feeding pump | G1",G1.5" , G2"aro diaphram pump | Brand: Ingersoll Rand |

| 10 | Operating control | button type or PLC (optional) |

Packing and delivery: Wooden boxes and FUL or LCL container

Related products:

Allwin also offer related grinding mediums and dispersing machines for grinding and dispersing processing.More informations can contact our sales manager.

The After sales service:

1. Video instructions for installation and commissioning, if need,

we will arrange engineer to your factory.

2. 12-24H feedback any customers questions, firstly offer the video

help you solving, if need arrange maintenance engineer for you.

If need more detailed information and price ,please contact us soon and warmly welcome to visit us!

|