| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Stainless Steel Casting |

|---|---|

| Brand Name: | NC9834 |

| Model Number: | 9834 |

| Certification: | ISO9001,CE,SGS |

| Place of Origin: | Mainland China |

| MOQ: | 100 pcs |

| Price: | Can talk |

| Payment Terms: | T/T, L/C, |

| Supply Ability: | 60,000 pcs monthly |

| Delivery Time: | 35 days |

| Packaging Details: | Wooden Case |

| Item Name: | Construction Hardware |

| Application: | Construction |

| Material: | Stainless Steel |

| Process: | Silicon Sol Casting |

| Drawing Types Accepted: | CAD ,STP , PDF ,3D, Files |

| Standard: | GB ASTM AISI DIN BS |

| Company Info. |

| Sunrise Foundry CO.,LTD |

| Verified Supplier |

| View Contact Details |

| Product List |

Construction Hardware Stainless Steel 304 316 Investment Casting Silicon Sol Casting

| Product Name: | steel Investment casting /steel precision casing / lost wax casting |

| Materials: | stainless steels, alloy steel, aluminum |

| Items: | FOB |

| Lead time: | 30 days |

| Place of Origin: | China |

| Software for specification drawings: | PDF, Auto CAD, Solidworks,JPG,Pro-E |

| Main production equipments: | wax injection, CNC-machine, machine-center,Heat treatment Furnace. |

| 1) We can do different kinds of surface treatment after casting, such as machining, polishing, and plating. | |

| 2) We make them by steel precision casting, steel investment casting , lost wax casting( lost wax casting,lost foam casting ) and steel sand casting process in Taiwan | |

| 3) Machine parts (machining parts or machinery parts), metalwork (metal products) and stamping parts . | |

| are suitable to us. | |

| 4) They are using for oilfield drill machinery, pipe connection and others | |

Technical Support

Sunrise Foundry is professional at independent development and design. Our engineers are skilled at AUTO CAD, PRO ENGINEER, SOLID WORKS and other 2D & 3D softwares. We are able to design, develop,produce

and deliver your PO according to your drawings, samples or just an idea. Dual control of standard products and OEM products.

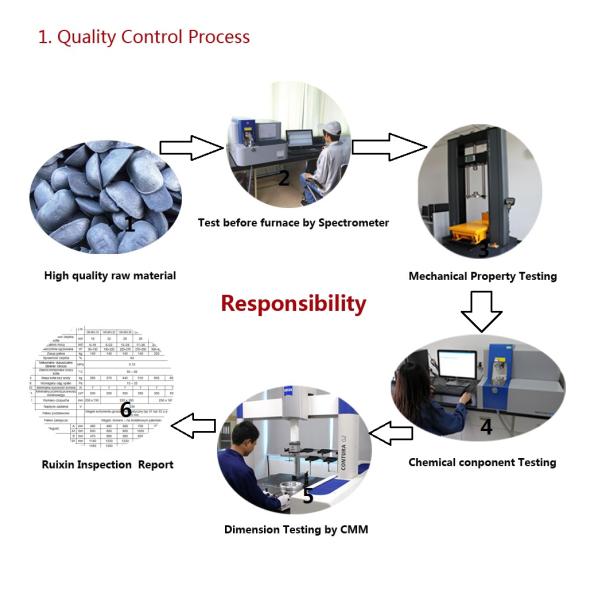

3,Quality Control

1) Checking the raw material after they reach our factory-------

Incoming quality control ( IQC)

2) Checking the details before the production line operated

3) Have full inspection and routing inspection during mass

production---In process quality control(IPQC)

4) Checking the goods after they are finished---- Final quality

control(FQC)

5) Checking the goods after they are finished-----Outgoing quality

control(OQC)

Product Show

Production Process

Quality Control

Our Service

Samples available any time, NO MOQ.

Reply your inquiry within 1hr in working time, with 12 hours in

non-working time.

Customized Service, OEM and ODM acceptable.

Warranty: One year, New replacement or spare parts will be sent

within the warranty period.

shipping cost will be covered by us.

|

|