| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Sand Mill Machine |

|---|---|

| Brand Name: | AllWin |

| Model Number: | SP100,SP250 |

| Certification: | ISO9001 |

| Place of Origin: | China |

| MOQ: | 1-5sets |

| Price: | USD32000-68000/set |

| Payment Terms: | T/T, MoneyGram, Western Union |

| Supply Ability: | 30sets /month |

| Delivery Time: | 20-30 Working Days |

| Packaging Details: | Wooden boxes |

| Inner cylinder material: | silicon carbide, or other materials for optional |

| Power: | 55 kw /75KW |

| Voltage: | 380 V/220V/415V |

| Manner of discharging: | static |

| Litre: | 100L,250L |

| Disperser's material: | stainless steel, 9Cr18Mo alloy steel, PU coated with stainless steel |

| Motor: | Ex-proof or non ex-proof motor |

| Disperers' structure: | disc type, or disc combined with turbine |

| After-sales service provided: | Video technical support,Online support |

| Outter chamber material: | Stainless Steel |

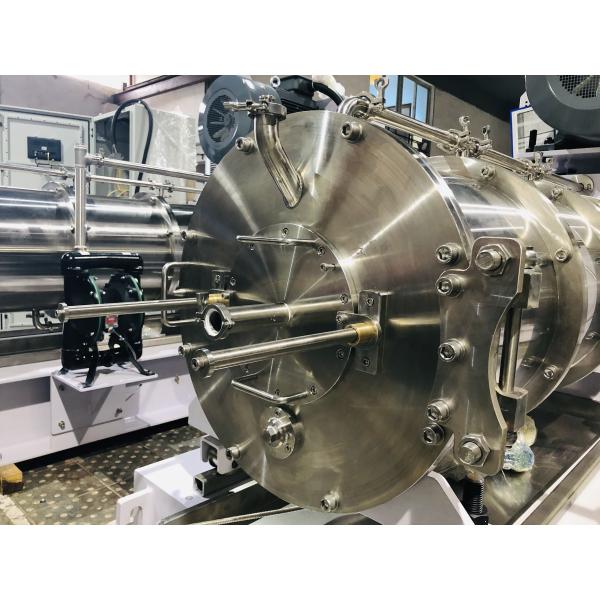

Nano Grinding Sand Mill Machine With High Advanced Technology For Industrial Production

Grinding sand mill machines are used in so many industrials like paper making , printing inks, electronic inks, ceramics ink, MLCC, paint, coat, pigment,etc. While, each seperative field has difference,especially in fineness and slurry particles and solid content when grinding,which means we should suggest the proper sand mills according to different customers and fields.

While how to choose an appropriate bead mill,that's a question for many customers.

Firstly, grinding is a key processing in whole procedure,the fineness must can basicly reach your requirement.

Secondly, the output efficiency is a core element.

Thirdly,mill machines are serrious of enery comusption , energy saving is a great advantage.

Lastly, other considerations like human labor or customized service will be great.

Allwin brand grinding mills are easy to install, and operation is rather humanized considering the safety, working comfort level,etc. All mills are tested before shipping, which makes sure of availability after mills reach to your side. The installstion can be operated with attached installation and maintainence instructions. If there are other problems need our assistance, contact us, we offer on-line assistance as soon as possible.

Main instructions:

| No | Main parts | SP100 /SP250 | Notes |

| 1 | Outer cylinder | 304 stainless steel | |

| 2 | Internal cylinder | silicon carbide ceramics | other materials are optional |

| 3 | Dispersing shaft | 40Cr with hard chromium plating | Brand: NSK |

| 4 | Dispersing disk | 304 Stainless steel | |

| 5 | Mechanical seal | Double end Mechanical seal with Pressure of 0.45 Mpa | |

| 5 | Feeding and discharging end covers on the cylinder | 304 stainless steel | |

| 6 | Turbine centrifugal separator and pegs | 304 stainless steel and YG6 pges | |

| 7 | Static discharge screen ring | 304 stainless steel screen ring with 304.Gaps: 0.5mm. | |

| 8 | Bearing | NSK | |

| 9 | Feeding pump | 1.5" aro diaphram pump | Brand: Ingersoll Rand |

| 10 | Operating control | button type or PLC (optional) |

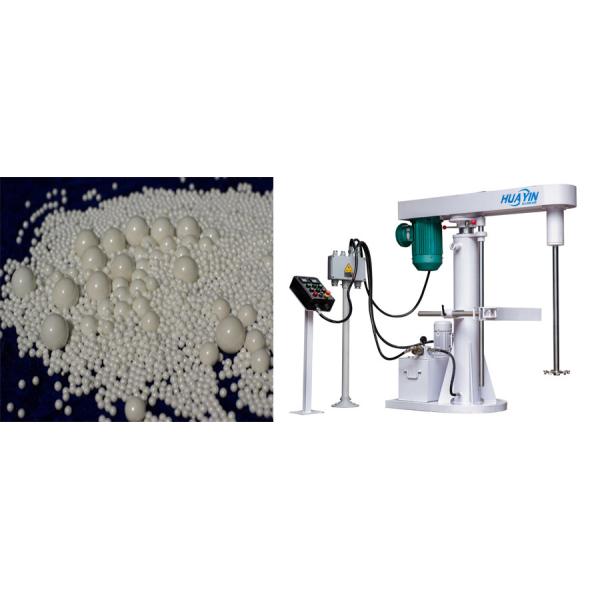

Related products:

Allwin also offer related grinding mediums and dispersing machines for grinding and dispersing processing.More informations can contact our sales manager.

The After sales service:

1. Video instructions for installation and commissioning, if need, we will arrange engineer to your factory.

2. 12-24 hours feedback any customers questions, firstly offer the video help you solving, if need arrange maintenance engineer for you.

FAQ:

Q1:Trading company or manufacturer?

A1: We are the manufacturer.

Q2: Is it available if we want to visit your plant?

A2: Yes, of course. Warmly welcome you to visit our factory to know our process, our technology.and communication face-to-face is rather benecial to built trust degree.

Q3: Do you have own R&D team?

A3: Yes, we have 12 engineers, and our products could be customized for your requirements.

Q4: How about the quality?

A4: We have professional engineers and a strict QA& QC system, Our factory comply with the IS09001 standard strictly. Warranty of all new disperser is one year free.

If need more detailed information and price ,please contact us soon and warmly welcome to visit us!

|