| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | PET Recycling Line |

|---|---|

| Brand Name: | BEAKELAND |

| Model Number: | 1000KG/H |

| Certification: | CE |

| Place of Origin: | JIANGSU,CHINA |

| MOQ: | 1 SET |

| Price: | Negotiation |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram |

| Supply Ability: | 10 SET/ YEAR |

| Delivery Time: | 65 WORKING DAYS |

| Packaging Details: | Standard Export Package |

| Keywords: | PET Washing Recycling Machine Line |

| Application: | PET bottle recycling |

| Production capacity: | 800-1000kg / h |

| Voltage: | 380V,50HZ,3P(customized) |

| Final products: | PET flakes |

| Final moisture: | 1 - 2% |

| Material processed: | Crushing washing drying |

| Part contact with material: | SUS304 |

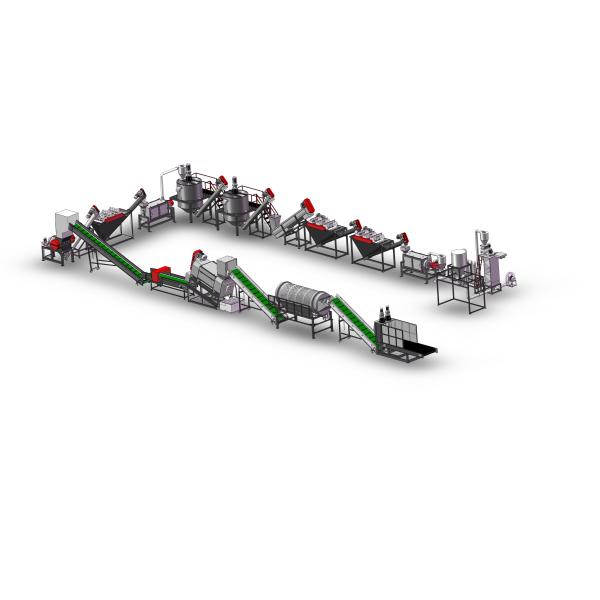

Stainless Steel Plastic Bottle Recycling Machine 800kg H Pet Bottle Washing Line

Post-Consumer Plastic Bottle PET Washing Recycling Machine Line

Despriction:

PET bottle washing line is the best solution for PET bottles recycling and washing. The complete washing machine line could turn baled dirty polyester bottles into clean and dry PET flakes which could used be pelletized to granulas or for PET fiber making. This line is controlled with a central electrical control panel from the begining to the end

Components of a typical PET bottle washing plant :

Models&specifications:

| Model | BKL-500 | BKL-1000 | BKL-1500 | BKL-2000 | BKL-3000 |

| Capacity(kg/h) | 500 | 1000 | 1500 | 2000 | 3000 |

| Installation Power (kw) | 150 | 250 | 300 | 400 | 500 |

| Labor | 2-4 person | 3-5 person | 5-6 person | 6-8 person | 8-12 person |

Final PET products quality for reference:

Machine line Features:

Detailed Photos:

Debaler

Sorting conveyor Crusher

High friction washing machine Water Label remover

Hot washing machine Washing line parts

|