| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Steel Pipe Production Line |

|---|---|

| Brand Name: | ZTZG |

| Model Number: | ERW 89 |

| Certification: | ISO9001 |

| Place of Origin: | China |

| MOQ: | 1 |

| Price: | Negotiable |

| Payment Terms: | T/T, L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 200 sets/year |

| Delivery Time: | 120 days |

| Packaging Details: | All mechanical equipment is nude packing and electrical parts are packed in wooden cases |

| Item: | Steel Pipe Production Line |

| Raw Material: | Carbon steel, black steel, stainless steel, Steel, HR carbon steel, Q235,S235 |

| Diameter: | 42-89mm |

| Thickness: | 2-6mm |

| Prodution Capability: | 20-120m/min |

| Applicable Industri: | Manufacturing Plant, Construction works, Energy & Mining, Tube mill |

| Welding type: | Solid-state high frequency welding |

| After Warranty Serve: | Video technical support, Online support, Spare parts, Field maintenance and repair service |

| Local Service Location: | Egypt, Turkey, Philippines, Brazil, Peru, Saudi Arabia, Mexico, Russia |

| Marketing Type: | New Product 2021 |

| Warranty of core part: | 1 Year |

| Core Components: | PLC, Engine, Bearing, Gearbox, Motor, Un-coiler, Hydraulic shear |

| Video outgoing-inspection:: | Provided |

| Machinery Test Report:: | Provided |

| Marketing Type:: | New Product 2020 |

| Warranty of core components:: | 1 years |

Machine Introduction

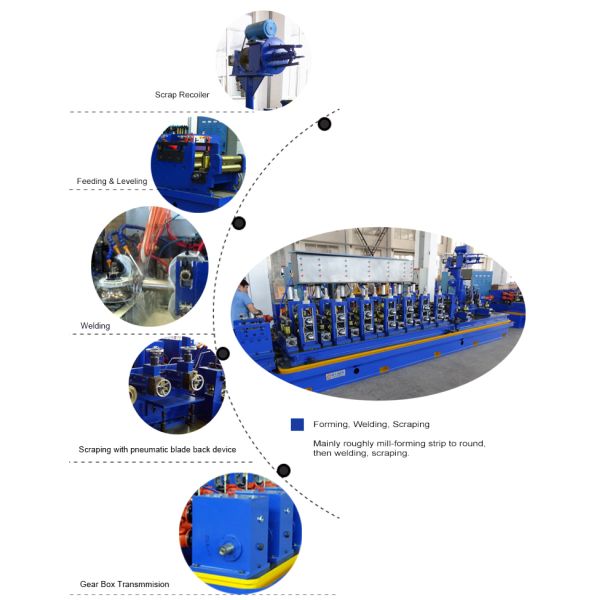

High-frequency welded pipe machinery is the production of low carbon low alloy steel material welded pipe special equipment, the specifications of the steel belt feeding machine will do the trick, by forming roller steel with curled up into a tube, then using high-frequency proximity effect and skin effect for tube side heat quickly to welding temperature, and under the squeezing roller extrusion complete welding, then through cooling, Sizing and roughing to the required size of steel pipe.

Steel coil→→ Double-head uncoiler →→Strip-head Cutter and welder→→Spiral Accumulator→→Forming section(Flattening unit +Main driving unit +Forming unit +Guide unit +High frequency induction welding unit +squeeze roller)+ Deburr frame →→Cooling unit →→ Sizing unit and straightener →→Flying saw under computer-control →→ Run-out table

Application

1. Waterpipe

2. Heating pipe

3. Low-pressure process pipeline

4. Low-pressure fire fighting a pipeline

5. Sewage Pipes

6. Steel Scaffolding Pipe

7. Wire and cable protection pipe

8. Structural support Steel Pipe

9. Industrial Steel Pipes

10. Decoration Pipe

11. Oil & Gas Pipes

Main advantages:

High production efficiency,

Highly automated

High strength, the machine can run at high speed and stably,

improve product quality

Reduce production losses

Save roller changing time

Save rollers

FAQ

Q: Are you a manufacturer?

A: Yes, we are a manufacturer. We have 4 factories ( Machining,

Assembling, Heat treatment, and Moulding ). We also have our own

R&D department. Welcome to visit us.

Q: What kind of payment term do you do?

A: We do T/T.

Q: What info do you need before giving me the price and proposal?

A: Since we design individual machines based on our customer's

requirements, we need your desired products' basic dimensions,

including all the pipe diameter(or tube length), thickness range,

usage, raw material steel grade, coil weight, and degree of

automation.

Q: What should I do if I just start a new business?

A: Contact us immediately, we provide a free consultant for

pre-sales service. Also, we can help you solve the raw material

(steel coil) purchase, worker training, international market price,

and more.

Q: How do you do QA?

A: We have a special team to do strict QA, this is one of our

strengths:

(1)Every gearbox will be tested for 8 hours with oil inside to

guarantee there is no leak.

|