| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Wedge Wire Screen Pipe |

|---|---|

| Brand Name: | Heng Yuan |

| Model Number: | HY122101 |

| Certification: | ISO,CIQ,CE, FORM E etc |

| Place of Origin: | Hengshui City,Hebei,China |

| MOQ: | 1 pcs |

| Price: | Negotiation |

| Payment Terms: | L/C, L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 1000pcs/Month |

| Delivery Time: | 7 days |

| Packaging Details: | Moister-Barrier with each piece,64 pcs per 20GP container |

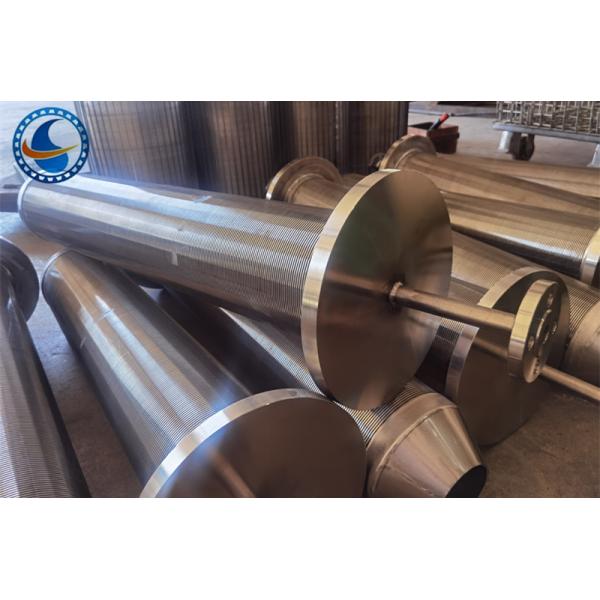

| Name: | Wedge Wire Profile Wire Screen Pipe |

| Material: | Stainless Steel |

| Diameter: | 168mm |

| Length: | 1200mm |

| Slot size: | 1.0mm |

| Wire: | 1.5*2.0mm |

| Support rod: | 2*3mm |

| Surface: | Polished |

| Ends: | Flange |

| Hole shape: | Vee-shaped |

| Package: | Wooden box |

| Filter type: | From outside to inside |

| Company Info. |

| Anping County Hengyuan Hardware Netting Industry Product Co.,Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

Wedge Wire Profile Wire Screen Pipe is made of a screen strip and a support strip (support strip). The wire screen is generally a triangular wire, and the support bar may be a round wire, a triangular wire, a trapezoidal wire or a square steel.

The profile wire are triangular wires (V-shaped wires).

The profile wire is also called a wrap wire, and the profile wire

of Wedge Wire Screen tube product is wound by a sieve bar and

finished to form a screen.

Name | Wedge Wire Profile Wire Screen Pipe |

| Material | Stainless steel 304, 304L, 316L and 321 etc. |

| Profile Wire | 1.0 *2.0 mm 1.5*2mm 1.5*2.5mm 2*3mm 2.3*3.5mm 2.2*4mm 2.2*4.5mm,3*4.6mm,3*5mm etc |

| Support Rods | 2*3mm 3*4mm 3*4.6mm 3*5mm 3*6mm 4*7mm |

| Round | From 2.5mm to 6.0mm |

| Slot Size | 0.025mm, 0.15mm, 0.25mm, 0.3mm ... 100mm etc |

| Pipe Length | Max 6 meter |

| Pipe diameter | 25mm to 1300mm |

| Screen Ends | Plain Beveled ends, male/female threaded, flange or close up. |

1. Production process continuity: V-shaped profile wires creating

slots which enlarge inwardly and therefore avoid clogging and

minimize downtime.

2. Low maintenance costs: Separation at the screen surface which

can easily cleaned by scraping or back washing.

3. Maximum process output: Precise and continuous slot openings

resulting in accurate separation without loss off media.

4. Low operational costs: Large open area with an effective flow,

high yield and a low pressure drop (dP)

5. Long live: Welded at each intersection creating a strong and

durable screen.

6. Reduced installation costs: supporting constructions eliminating

costly support media and enabling a maximum flexibility in the

design of components.

7. Chemical and thermal resistant: A variety of corrosion resistant

stainless steel materials and many exotic alloys suitable for high

temperatures and pressures.

|