| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Horizontal Bead Mill |

|---|---|

| Brand Name: | AllWin |

| Model Number: | SP30 SP50 SP100 |

| Certification: | ISO9001 |

| Place of Origin: | China |

| MOQ: | 1set |

| Price: | USD23000--USD45000/set |

| Payment Terms: | T/T, Western Union, MoneyGram |

| Supply Ability: | 30sets /month |

| Delivery Time: | 20-30 working days |

| Packaging Details: | Wooden box |

| Materials: | silicon carbide ceramics |

| Power: | 30 37 55kW |

| Volume: | 30 50 100L |

| Fineness: | <10 um |

| Output capacity: | 300-1500 Kg/h |

| Application: | furniture paint,emusify paint,corrosive paint,car paint,etc |

| Explosion performance: | EX-proof, flammable |

| Voltage: | 220V 380V |

| Screen gap: | 0.5mm |

| Grinding bead: | 95% zirconia beads |

30% Enery Saving Ceramics Wet Grinding Horizontal Bead Mill Machine For Paint Production

Hrizontal bead mill machines are one of the most important

equipments in processing flow, and you can have many types of bead

mill for option. While disk type is the most widely used, and

ceramics cylinder chamber is the best for its great wear resistance

and heat dissippation,especially for those which have tough

requirement of grinding temperature and white color.

The main parameters of Sand Mill Machine:

| No | main parameters | SP30 | SP50 | SP100 | Note |

| 1 | Explosion-proof motor kW | 30kW | 37kW | 55kW | (Ex) |

| 2 | Effective volume of | 30 | 50 | 100 | |

| 3 | Water pressure (MPa) | 0.3 | |||

| 4 | Cooling water consumption (L/min) | 2.5 -3m3/h | Advise offer the Cooling water less 10°C | ||

| 5 | Dimension*W*H (mm) | 1840*900*2000 | 2000*900*2000 | 2200*900*2000 | |

| 6 | Weight (kg) | 1350 | 1650 | 2000 | |

The main instructions:

| No | Main parts | SP30 SP50 SP100 | Notes |

| 1 | Outer Chamber | 304 stainless steel | |

| 2 | Inner Chamber | silicon carbide ceramics | |

| 3 | Dispersing shaft | 40Cr with hard chromium plating | |

| 4 | Dispersing disk | 304 stainless steel | |

| 5 | Feeding and discharging end covers on the chamber | 304 stainless steel | |

| 6 | Static discharge screen ring | Wire Wound screen ring with 304 stainless steel ,Gaps: 0.5mm. | |

| 7 | Mechanical seal | Intelligent double mechanical | Allwin technology |

| 8 | Feeding pump | SP30 /SP50 with 1” ARO diaphragm pump; | |

9 | Appliance configuration | Explosion-proof machine, suitable for water base materials, motor 30 /37/55kW. Explosion-proof parts: operation column, electrical appliance boxes; electric contact pressure gauge, temperature, solenoid valves with ex electrical contacts. | |

| 10 | Fasteners and connecting parts | Stainless steel clamp-type | Quick and convenient |

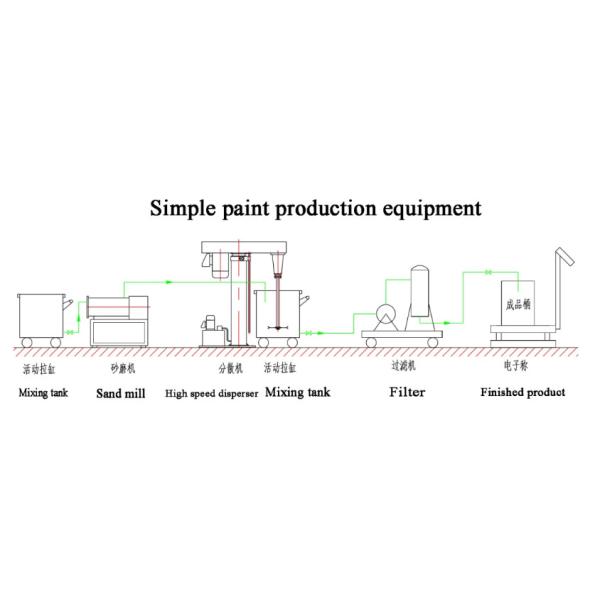

Simple prodution processing flow for paint

Other related machines

The After sales service:

1. Video instructions for installation and commissioning, if need, we will arrange engineer to your factory.

2. 12-24H feedback any customers questions, firstly offer the video help you solving, if need, arrange maintenance engineer for you.

The package and shipping: Be covered with anti-abrasion film and then packed in wooden boxes, then seashipping by FCLor LCL.

If any detailed information and price ,pls contact me, also warmly welcom to visit us.

|