TOBO GROUP sales head offce in Shanghai.

We are one of the Professional manufacturers Exporter Pipeline

products in China .Our company was established in 1998, the plant

covers 550, 000 square meters and a construction area of

6,8,000square meters, existing 260 workers and 45 technicians.

We have five branch factories which can supply the best quality

pipes, tubes, fittings flanges and related accessories. Now, it

owns a number of advanced pipe production equipments, metal,

forging, machining, cold forming, hot extrusion, such as heat

treatment process, producing 60, 000 tons of pipe fittings. Company

with a variety of detection devices, such as nondestructive

testing, chemical analysis, metallographic examination, physical

experiments. The technical is very strength, our main products

contain fittingsforged socket welding fittings and threaded

fittings, pipe weld and the materials of the products contain

stainless steel ,duplex-stainless steel alloy steel.

In addition, we are authorized by more than 120 top-class mills

from South Korea,Japan and China like JFE,SUMITOMO,POSCO,BAOSTEEL,

TISCO,LISCO,.TPCO,HENGYANG VALIN and so on .

Our main products as follows:

Stainless steel pipe & tube

(seamless pipe / welded pipe / square pipe / rectangular

tube,duplex stainless / inconel tube)

Carbon / alloy steel pipe & tube

(seamless pipe / ERW / SSAW / LSAW / UOE / hollow section pipe /

Galvanized Pipe)

(line pipe,water pipeline,gas pipeline,oil pipeline)

(copper tube/titanium tube/aluminium tube/nickel alloy )

(round bar/angle steel /flat steel/channel steel/steel wire)

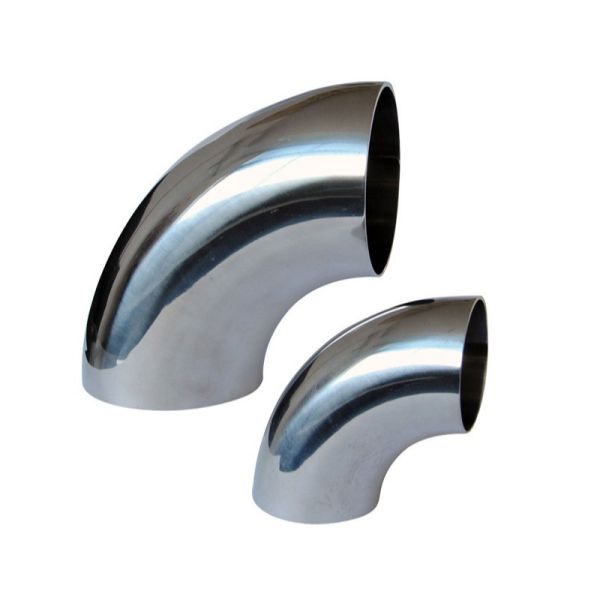

(eblows, equal / reducing tees, concentric/eccentric reducers,

caps, crosses, bends, dish end/end cup, stub ends, unions,

couplings / hex couplings, swage nipples , nipples, hex. plug,

sockolet, weldolet, thredolet, etc)

(DIN flange/ AISI flange/blind flange/welding flange/stainless

flange/slip on flange)

(stainless steel/carbon steel/alloy steel/galvanized

steel/aluminium )

(ball valve/gate valve/butterfly valve/globe valve/swing check

valve/ check valve)

In order to comply with the global modernization services

development trends and eliminating the varieties distress of the

global enterprise‘s purchase in the consumables.. We coordinate the

pressure pipe manufacturer which with the scale of

production,quality control and high cost performance (has passed

ISO 9001 quality series attestation, ccs,

DNV,PED/97/23/EC,AD2000-WO,special equipment manufacturing

license,ASME-SA182.through a variety of effective assort mechanism

to make up the shortage of supply and Post-processing of VAT

enterprise, and to supply high quality pipe fittings, because of

the superior quality and good service, we have established long

term business cooperation with more than 60 countries and

areas,which covers Europe, Africa, South America, North America,

Middle East, Taiwan and South East Asia and so on.

With many years effort and support from our valuable customers,

these products have obtained a big market share in the world.

Our business principle is "Superior quality, Competitive price,

Timely delivery and Considerate service " Standing to the principle

of “Enterprises focus on the core business”, TOBO will actively

promotes the globalization of business strategy approach, using

advanced supply chain management technology to service for clients

with higher quality and more competitiveness ‘ s products. At the

same time, we sincerely reply your inquiry, honesty waiting for

your visiting and wish to have cooperation with you at the any

time. We welcome all the customers to contact us for more

information. We assure you, with our technical knowledge and

experience, our company will be one of your Stable, Continuate

business parters in China.

info@tobo-group.com