| Sign In | Join Free | My benadorassociates.com |

|

| Sign In | Join Free | My benadorassociates.com |

|

| Categories | Horizontal Bead Mill |

|---|---|

| Brand Name: | Allwin |

| Model Number: | SH30/60 |

| Certification: | ISO9001 |

| Place of Origin: | China |

| MOQ: | 1 unit |

| Price: | USD30000---60000 Per Unit |

| Payment Terms: | T/T, Western Union, MoneyGram |

| Supply Ability: | 30 Units per Month |

| Delivery Time: | 20-30 Work Days |

| Packaging Details: | Wooden Boxes |

| Inner Chamber Matrial: | Stainless steel, 316/304 |

| Outter Chamber Material: | SUS 304 Stainless Steel |

| Dispersing structure material: | Stainless steel, 316/304 |

| Effective Volume: | 30L 60L |

| Motor Energy: | 22KW, 37kW |

| Application: | liquid medicine, capsule coat |

| Dispersing type: | pin type structure |

| Discharging manner: | static discharge |

316L Stainless Steel Horizontal Bead Mill Applicated In Pharmaceutical Industry

Food grade stainless steel wet grinding horizontal bead mills are

usually used in not only in food industry, but also in

pharmaceutical industry, such as liquid medicines and capsule

coates for other dry powder medicines.

1. Technical data of large flow horizontal bead mill

| No | Main Parameters | SH30/60 bead mill | Notes |

| 1 | Motor power (kW) | 22/30/37KW | Ex-proof/non ex-proof available |

| 2 | Effective volume of grinding chamber (L) | 30/60L | volume can be suggested according to different grinding materials and usages |

| 3 | Water pressure (MPa) | 0.3 | |

| 4 | Cooling water consumption (L/min) | 2.0 -2.5 m3/h | Advision: Users offer the Cooling water less 10°C |

| 5 | Dimensions:L*W*H (mm) | --- | |

| 6 | Weight (kg) | 1200---1700 | Different as for different chamber volume |

| No | Main parts | SH30/SH60 | Notes |

| 1 | Material of External vessel | SUS 304 stainless steel | |

| 2 | Material of Inner grinding vessel | SUS 304/316L stainless steel | different mateials for choice |

| 3 | Material of Dispersing shaft | 40Cr with hard chromium plating | |

| 4 | Material of dispersing system | 304/316L stainless steel | Choose what you need |

| 5 | Feeding and discharging end covers on the cylinder | SUS 304 stainless steel | |

| 6 | Static discharge screen ring | Wire Wound screen ring with 304.Gaps: 0.5 mm. | dynamic scraper: alloy steel |

| 7 | Mechanical seal | Double end mechanical seal | |

| 8 | Feeding pump | 1" ARO diaphragm pump | IngersoII Rand |

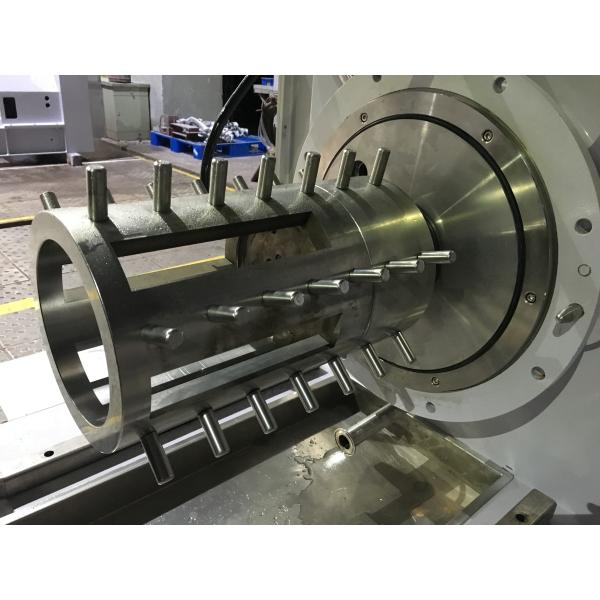

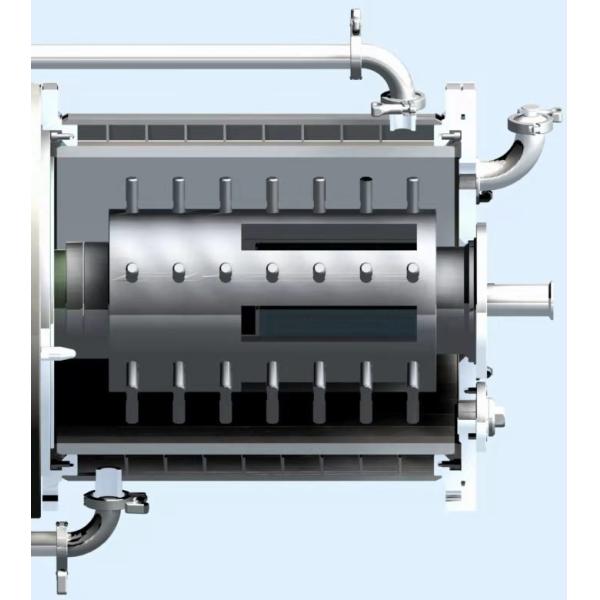

3. The pictures of processing and inspection

inner structure of grinding bead mills for SH series

1. Video instructions for installation and commissioning, if need, we will arrange engineer to your factory.

2. 12-24H feedback any customers questions, firstly offer the video help you solving, if need, arrange maintenance engineer for you.

If need more detailed information and price, please don't hesitate

contact us, Also Warmly welcome to visit us.

|